Sigma Purlins Machine

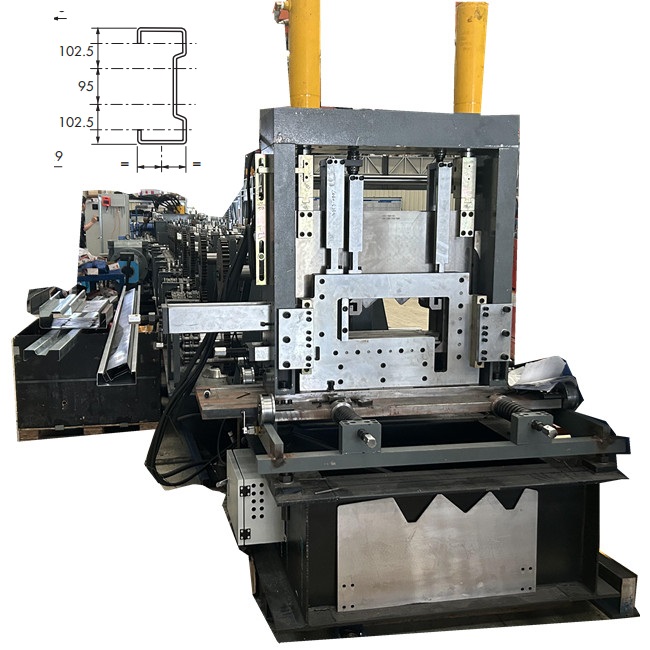

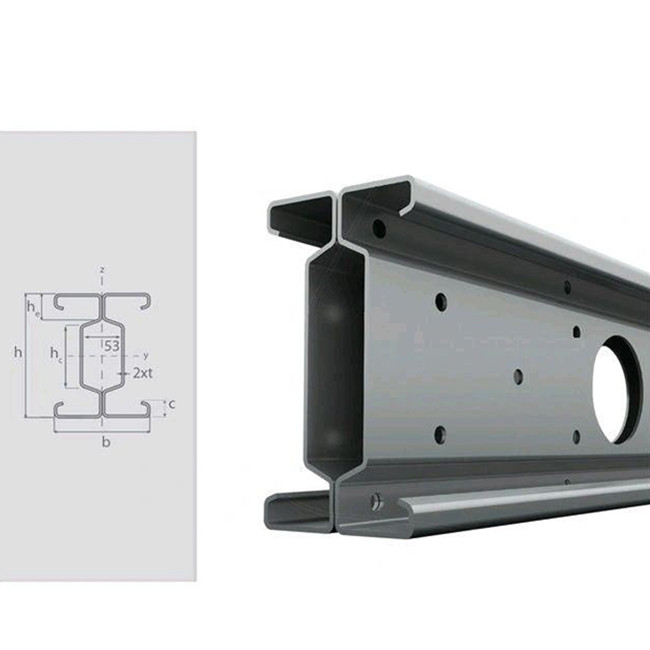

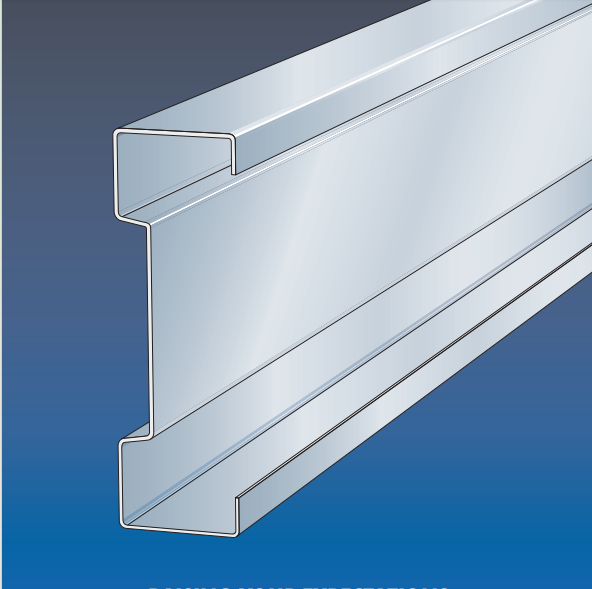

Sigma Purlins Machine is designed to make the sigma purline in batch fully automatically. Meanwhile it can be used to make C purline, U purline also. The sigma purlin system has been developed in conjunction with for many years. The system is designed primarily for use, on roofs, as secondary sheeting support.

Sigma sections are manufactured by cold roll forming pre-hot dipped galvanised steel, grade S450, having a minimum yield stress of 450N/mm2. Here we developed one rolling forming machine for making such profile with multiple punching.

The above range can not be made by one range, as thickness range too big, Normally thickness 1.5 to 4.0mm, or 3.5mm that will be better. Here are some usage for your reference:

Speed: 30 meters per minute, comprehensive speed of 12 meters per minute to 15 meters per minute (depending on the number of holes drilled);

1. C width (80~350) mm, Z width (120~350mm) can be freely transformed;

2. Small edge (8-20mm) and small edge ≤ 0.8 * (waist height -20);

3. Waist height (30-100) mm and waist height ≤ 0.95 * (bottom width - small edge -30);

4. Adjustable plate thickness t (1.0~3.5) mm;

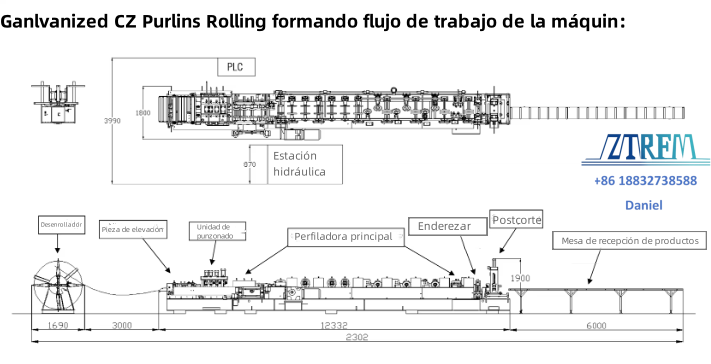

Working flow chat : Uncoiling → Feeding material into machine →Leveling → punching and pre-shearing →roll forming →Products receiving table

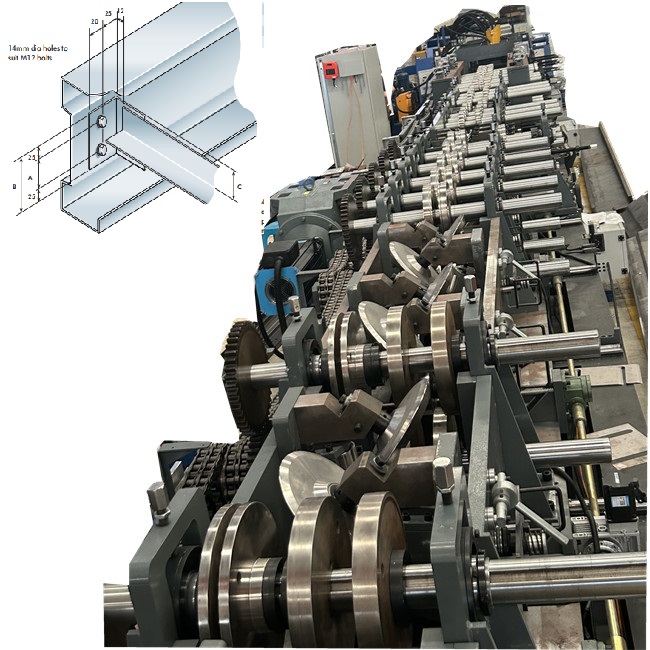

The first 8 roller station are for Sigma ribs width adjustable according the bottom width change. PLC control the width adjustable.

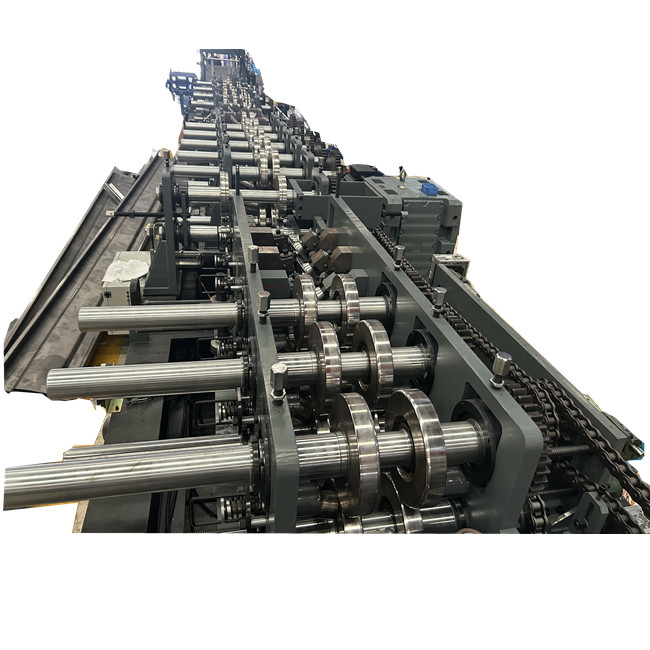

Diameter of shafts:Φ90 mm solid

Double row chain for transmission+shaft end support

Material of shafts:

40 Cr CNC processing HRC28-32 ,finish turning and electroplate

Forming speed: max 15m/min

Voltage: 380V/60HZ/3P (as requested)

Transmission way :

Double chains + shaft end support

Sizes changing: Automatically by PLC

C and Z purling change : By manual

Roll material: Cr12, precision machined inner hole after vacuum heat treatment

Processing technology: CNC machining followed by heat treatment to HRC58-60, precision machining

Shaft material: 40Cr (diameter 90/diameter 75)

Processing technology: quenching and tempering treatment HRC28-32 after CNC processing, and then fine turning and electroplating.

If you want to know more about this machines, please contact Daniel at any time and forever.