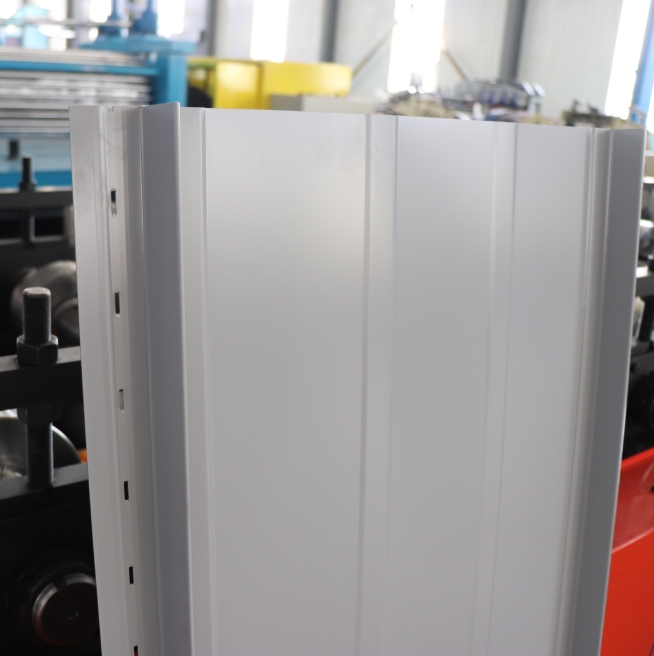

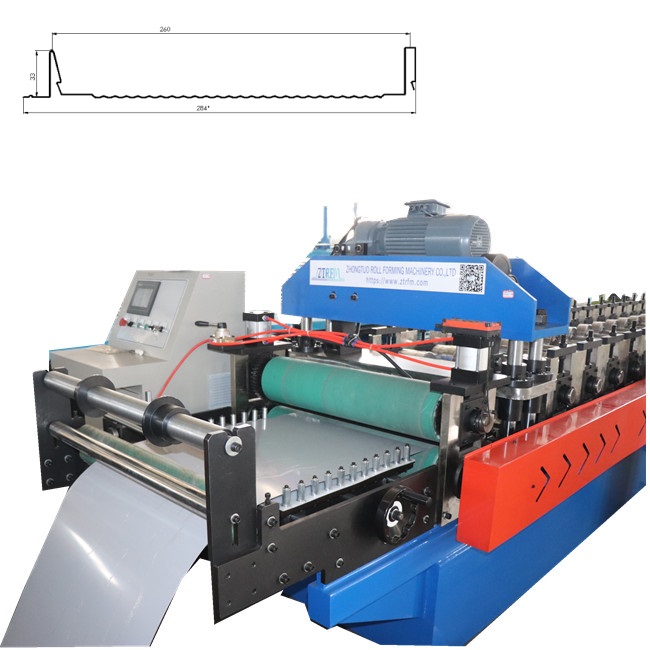

Snap Lock Standing Seam Roofing sheet machine

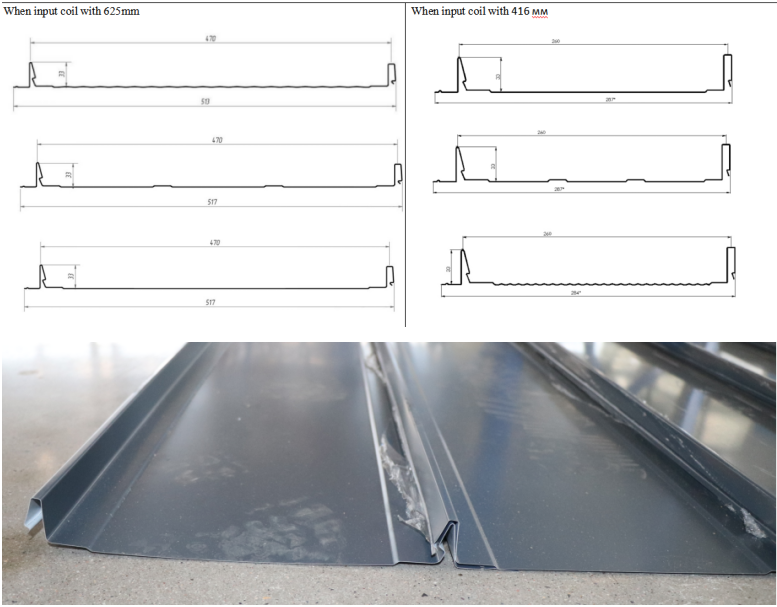

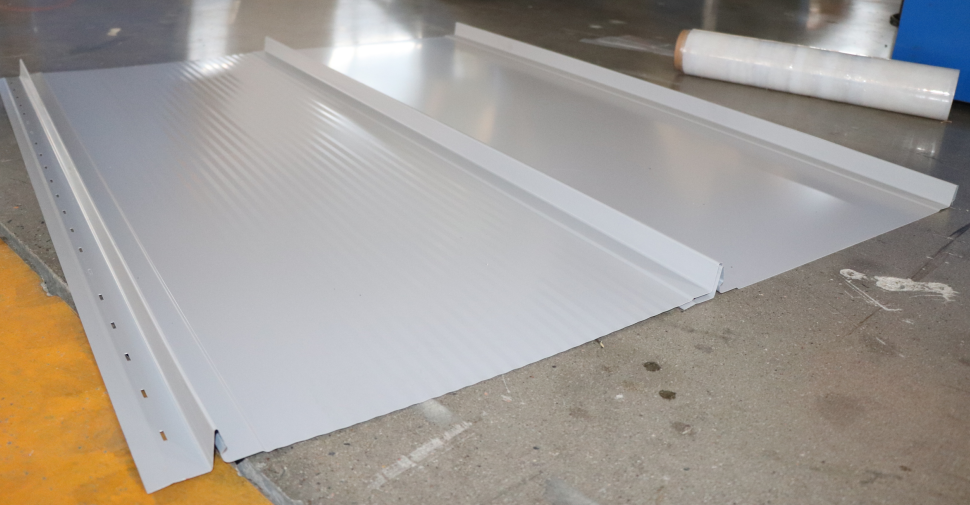

Zhongtuo's roof sheet roll forming machine was more and moer popular in all the world ,there are some different profile options for the roofing panels-including mechanical seam, snap-lock, and nail strip/fastener flange - are distinctly different in terms of performance, engineering and testing, slope requirements, attachment method, price, and so on. Here we will introduce one type width adjustable standing seam profiles, snap lock type here, also the metal embossing type also adjustable. Here are some drawing profiles for your reference:

There are two types width adjustable: when you use narrow strip or wide coil, you can choose the width range according to your requirements: As to the bottom ribs embossing pattern, we can design according to your requirements.

Here are some parameters for your reference: | |

Feeding device | One set guiding roller |

Steel plate welded platform to carry the sheet and feed into roll forming system | |

Feeding width is adjustable with the handle wheels | |

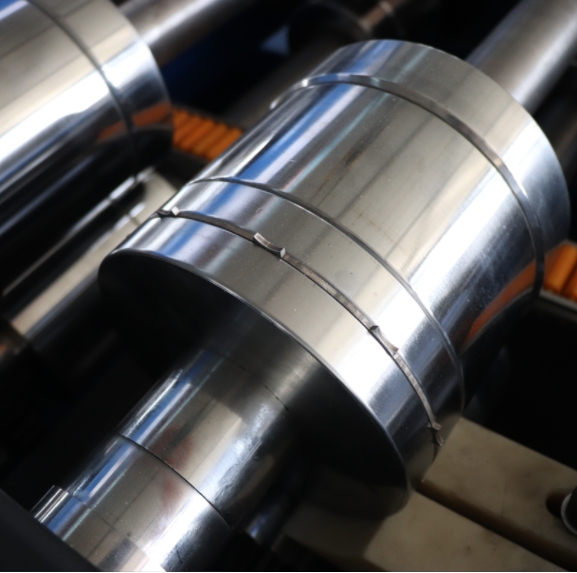

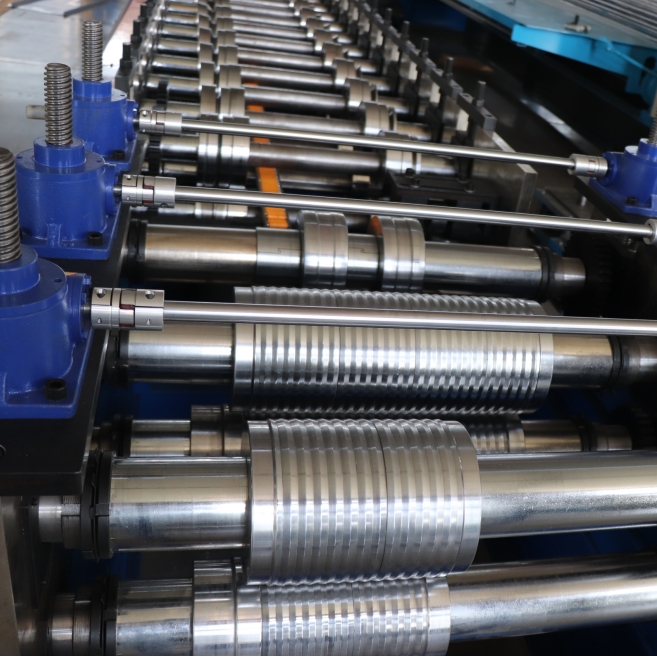

Rolling shaft Roller | Shaft material:45# STEEL |

Shaft diameter: 75 mm | |

Tempering treatment to prevent deformed and improve hardness | |

45# steel | |

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Rolling station | 21 roller station |

Work speed | 20 m/min |

Machine structure | Steel plate welded structure |

Machine basic frame | 500# H steel welded |

Work power | Main motor: 5.5 kw |

Rolling spacer | Anti rusty treatment |

Pull rod | Anti rusty treatment |

Transmission | By Chains with cover |

Noted: please fill the lube in case the chains getting dry | |

Comprehensive Technical Specifications of Snap Lock Standing Seam Roofing Panel Roll Forming Machine

Modern architectural demands require precision-engineered roofing solutions, and our Snap Lock Standing Seam Roofing Panel Rolling Forming Machine represents the cutting edge in metal panel fabrication technology. Designed for both industrial-scale production and specialized custom projects, this machine incorporates seven key technological advancements that ensure superior performance, durability, and output quality.

1. PLC-Automated Width Adjustment System

The machine features a programmable logic controller (PLC) that enables fully automatic width adjustment during operation. This computerized control system stores multiple width presets (typically 300mm-600mm adjustable range) and can switch between profiles within seconds through the HMI touchscreen interface. The servo-driven adjustment mechanism maintains ±0.3mm dimensional tolerance, eliminating manual measurement errors. This automation significantly reduces changeover time between different panel specifications while ensuring perfect seam alignment across production batches.

2. Multi-Profile Embossing Roller System

Our proprietary quick-change embossing roller cassette system accommodates 12-24 different profile configurations (including T-style, vertical leg, and double-lock variations). Each roller set is CNC-machined from 60Mn alloy steel with hardened surfaces (HRC58-62) for wear resistance. The dual-pressure embossing stations create crisp architectural lines and structural ribs with 0.1mm depth consistency. Special anti-vibration bearings prevent pattern distortion at maximum line speeds of 25m/min.

3. Linear Motor Drive Precision System

Unlike conventional chain drives, the direct linear motor propulsion delivers superior motion control with 0.05mm positional accuracy. The brushless servo motor (typically 7.5-15kW) coupled with magnetic linear guides achieves acceleration rates up to 0.5m/s² without slippage. This eliminates the "fish scaling" effect common in hydraulic systems and maintains consistent panel lengths (±1mm over 12m spans). The closed-loop feedback system automatically compensates for material thickness variations (0.4-1.2mm).

4. Heavy-Duty Roller Assembly

The forming mill incorporates 22-32 stations of forged Cr12MoV alloy rollers (80mm shaft diameter) with Timken tapered roller bearings. Each roller undergoes cryogenic treatment (-196°C) to enhance grain structure, achieving 50,000+ operating hours lifespan. The triple-support roller stands prevent deflection when forming high-strength materials (up to 550MPa yield strength). Automatic centralized lubrication ports deliver grease to all critical contact points every 15 minutes.

5. Precision Snap Lock Mechanism

The patented snap lock forming station utilizes spring-loaded cam followers and tungsten carbide inserts to create interlocking seams with 0.15-0.3mm engagement precision. The dual-stage forming process first pre-bends the male leg at 145°, then completes the 90° final fold with 12-ton hydraulic pressure. This produces watertight joints that meet ASTM E1646 water penetration standards without sealants.

6. Configurable Side Locking System

Operators can engage/disengage the side locking function via the PLC interface based on material gauge requirements. The electromagnetic locking pins (6-12 positions adjustable) provide 360° circumferential support during the final forming stage. When disengaged, the system automatically retracts all components to prevent material scratching. Force sensors monitor locking pressure (adjustable 2-8 bar) to prevent panel deformation.

7. Aesthetic Side Roller Package

The finishing module includes 4-6 pairs of spring-loaded side guide rollers with polished DLC (Diamond-Like Carbon) coatings. These maintain panel flatness within 0.5mm/m while eliminating edge waviness. The adjustable roller pressure system (0-50kg/cm²) accommodates different material tempers without causing surface marring.

Economic Alternative: Fixed-Width Configuration

For projects requiring single-profile production, we offer cost-optimized fixed-width versions at 30-40% lower capital investment. These machines maintain the same core quality standards while eliminating the PLC width adjustment and some secondary features. Typical applications include large-volume residential projects or standardized industrial buildings.

Technical Support & Customization

Our engineering team provides comprehensive support including:

On-site installation & calibration (global service network)

Roller tooling design for custom profiles

Annual maintenance contracts with spare parts kits

So thank you can read this passage , more details can tell me , and send me message .