Comprehensive Technical Profile of Cangzhou Zhongtuo's Stone-Coated Tile Machinery

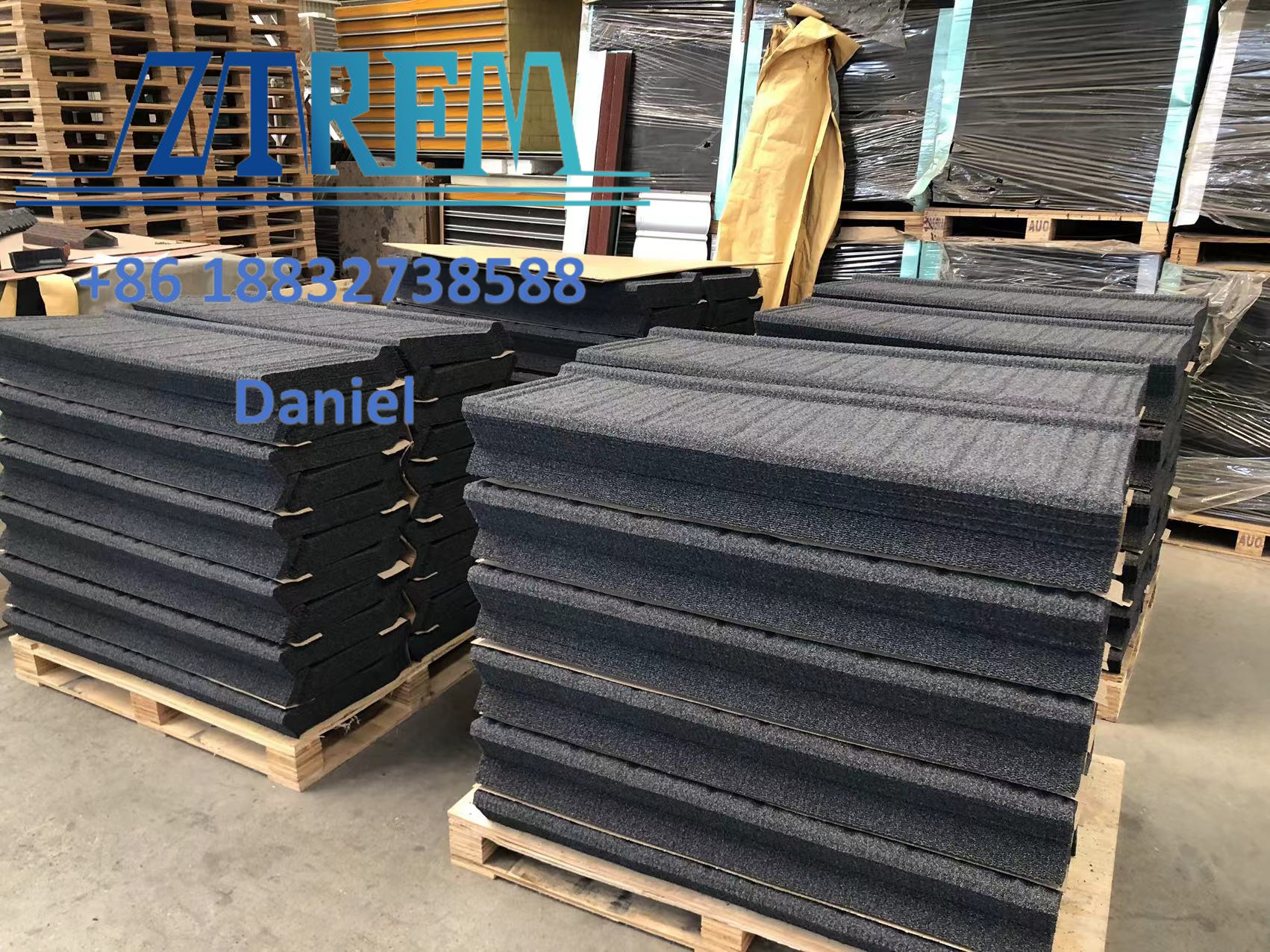

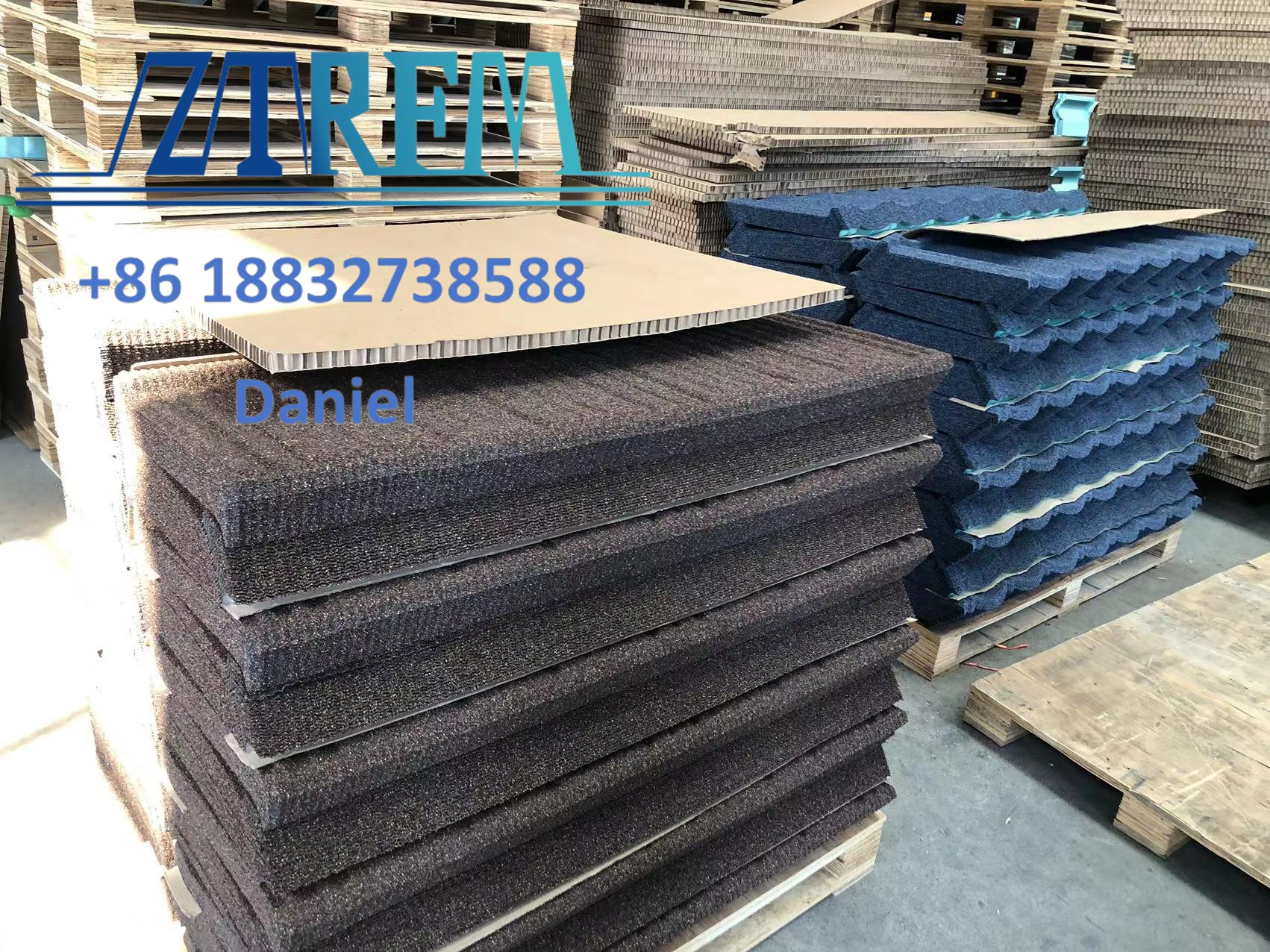

Stone-coated roofing sheet machine combine durability, aesthetics, and eco-friendliness. Stone coated roof tile making machine weather-resistant design withstands extreme conditions (UV rays, hail, heavy rain) while maintaining color vibrancy for decades. Lightweight yet strong, they reduce structural load and simplify installation, cutting labor costs.

I. Core Functional Advantages

1. Multi-Layer Composite Technology

8-Layer Material Integration: Processes substrates with alternating aluminum foil/polymer films/foam layers, achieving 35% better thermal insulation than conventional EPS panels while reducing weight by 22%.

High-Speed Bonding: 5-stage thermal lamination at 180°C ensures 0.02mm precision in adhesive distribution, eliminating warping defects common in single-layer materials.

2. Precision Hydraulic Forming

200-315T CNC Presses: Deliver ≤0.1mm dimensional tolerance for complex curved tiles (≥30cm radius), with servo-controlled pressure adjustments for varying thicknesses (0.3-1.2mm).

Dual-Mode Operation: Switchable between traditional PPGI sheets and composite materials without tooling changes, reducing setup time by 70%.

3. Automated Surface Treatment

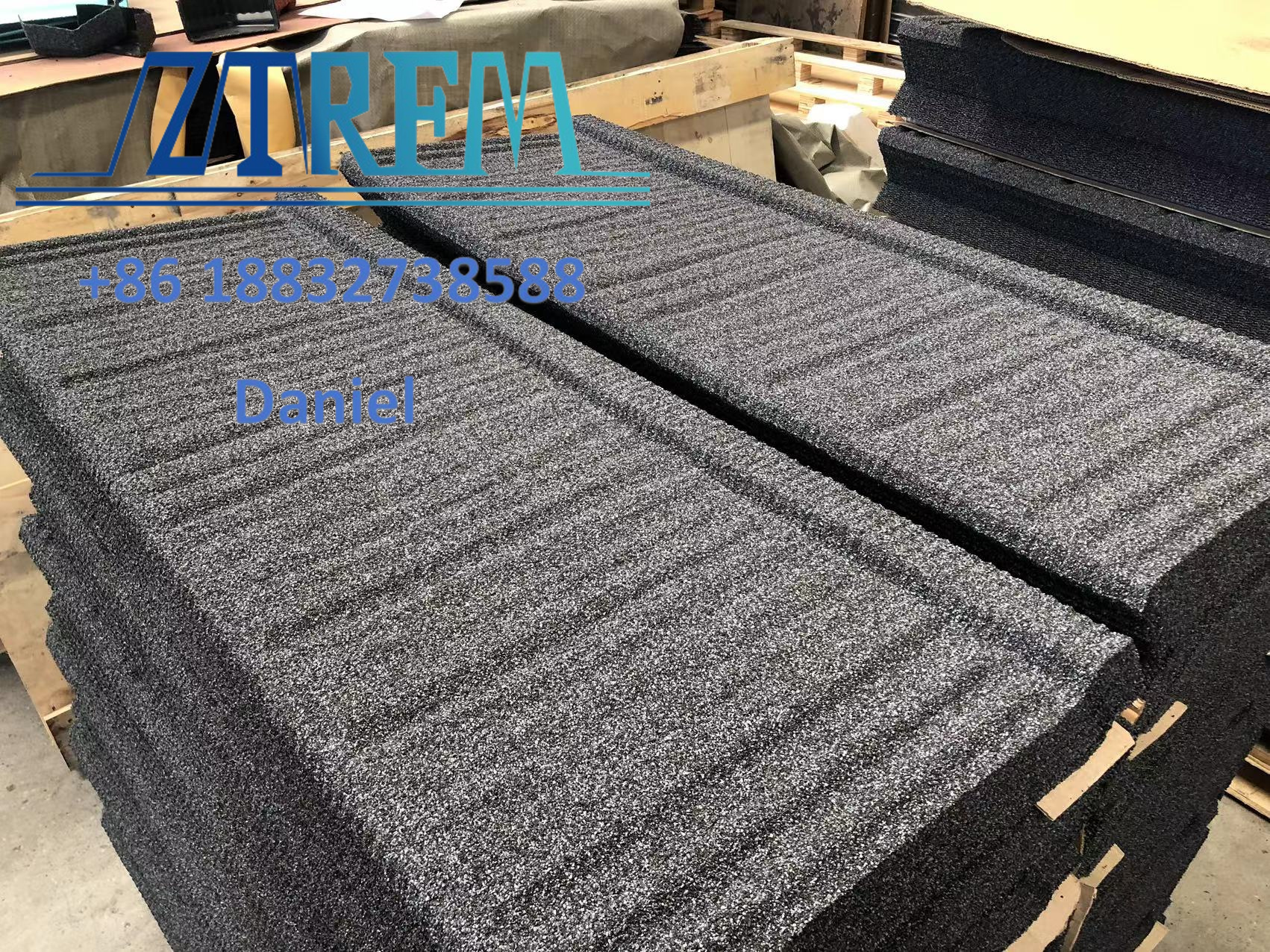

Robotic Spray System: Applies acrylic resin coatings at 12㎡/min with 98% coverage uniformity, embedded with quartz sand (3-5mm granules) for UV-resistant textures.

Closed-Loop Recycling: Captures 95% of oversprayed adhesives via electrostatic precipitation, cutting material costs by $1.2/㎡.

II. Market-Differentiating Features

1. Smart Manufacturing Integration

Siemens IoT Platform: Real-time monitoring of 23 production parameters (e.g., roller temperature ±1°C, hydraulic pressure ±2Bar) with predictive maintenance alerts.

Auto-Stacking Conveyors: AI-powered vision systems sort tiles by pattern/color at 120 pieces/min, reducing manual handling by 85%.

2. Energy Efficiency Innovations

Regenerative Drying: Recaptures 65% waste heat from coating ovens to preheat substrates, lowering energy use to 1.8kWh/㎡ (industry avg: 2.5kWh).

Modular Design: Allows incremental capacity expansion from 15㎡/h to 60㎡/h by adding parallel processing units.

3. Compliance & Certifications

Fire Safety: Meets ASTM E108 Class A standards with self-extinguishing composite cores (flammability index ≤25).

Corrosion Resistance: Salt-spray tested for 1,000 hours without blistering (equivalent to 50-year coastal service).

III. Commercial Benefits for Stakeholders

1. For Manufacturers

ROI Optimization: 18-month payback period via 40% labor reduction and 15% higher yield rates compared to manual lines.

Export Readiness: CE-marked configurations available for EU markets, with voltage adaptability (380V-480V, 50/60Hz).

2. For Architects/Contractors

Design Flexibility: Produces tiles mimicking slate (Chisel Edge), clay (Roman), or cedar shake profiles from the same machine.

On-Site Adaptability: Mobile decoiler units enable direct material feeding at construction sites, minimizing transport damage.

3. For Sustainability Advocates

Circular Economy: 100% recyclable output with 30% recycled aluminum-zinc content, qualifying for LEED v4.1 MR credits.

Carbon Footprint: 2.1kg CO₂/㎡ (vs. 3.8kg for conventional tiles) due to cold-forming process.

IV. Case Validation

Installation : Achieved 98.7% uptime in tropical storm conditions, producing 12,000 ㎡/month for hurricane-resistant roofing.

Client Feedback: 40% faster installation vs. imported European machines, with 30% lower spare parts consumption.