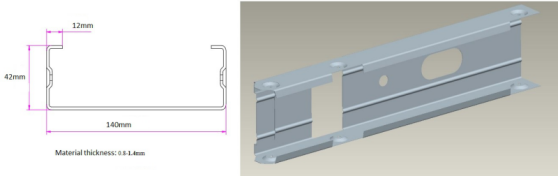

Villa Frame Rolling Forming Machine C140

C140 villa frame machine is designed to make C140 in batch fully automatically.

Compared with C89, C140 is much bigger than C89, C100 and others. C140 is good when you want to build higher layer building like 6 layers, 5 layers out wall stud and track.

Here is C140 villa frame machine pictures for your reference.

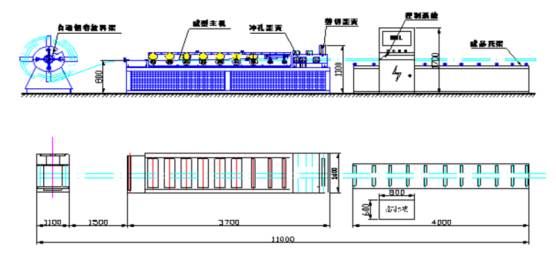

Machine working flow:

Supported material | G550 high tension grade plate, zine coated plate, 350 to 550 MPA (G 450 middle carbon steel in better.) |

Material thickness | 0.7 to 1.4mm |

Villa Frame Rolling Forming Machine C140

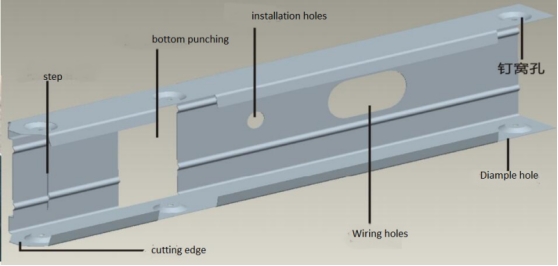

Main elements of the villa machine

Manul decoiler ID is 450 - 550mm Coil load 3 ton | |

Punchin device 6 sets Punchine die material (SKD11) 1.50X12mm side hole 2. Beehive holes 3.Function bolt for easy installation 4. 60x30mm for cable tray holes 5. 89x50 for the square holes 6. web hole and 45 degree bending or shearing. Note: if your country bolt sizes are different, please tell me in advance. |

|

Main rolling forming machine 1. Transmission, we use gear, chain as tranmission. 2. Main servo motor: 5.5kw 3. Roller material: SKD11 4. Shaft mateiral : 40Cr 5. Forming speed: 30m/min 6. Production capacity: 80 to 100 square meter per day, if you work 8 hours per day. | |

Shearing System Hydraulic station 1. Power: 5.5kw 2. Oil tank: 120OL 3. Brand: Yuken series |

|