High speed roofing sheet machine

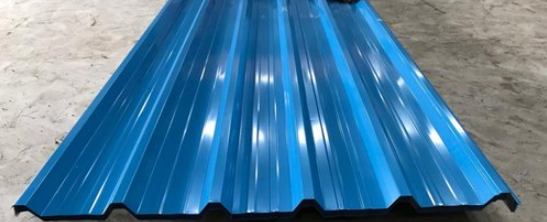

Description:High speed metal roof sheet rolling forming machine is designed to make the metal roofing sheets in batch fully automatic in the speed of 40 meter per minutes. Compared with the normal metal panel roofing sheet machine, its working efficiency is equal to normal one 3 times.

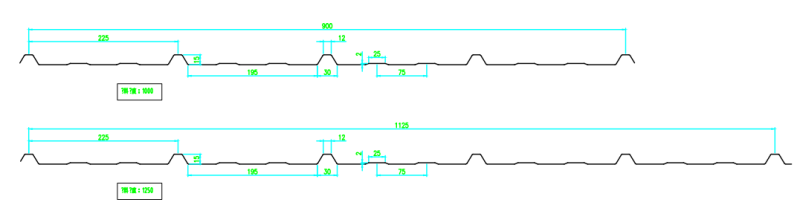

The machine we design use the gearbox as transmission, servo flying shearing tracking hydraulic cutting . The hydraulic decoiler speed also can reach 40 meter per minutes. This high speed machine is good fro those countries where the working salary is quite high. Take the following drawing profile for example to show how the High Speed Metal Roof Sheet Roll Forming Machine is designed.

According to the features, we design high speed metal roof sheet Roll Forming Machine like the following pictures:

Features of High speed metal roof sheet Roll Forming machine

1. Working speed can 40m/min, PLC control with the servo motor,flying shearing tracking hydraulic cutting, the shearing speed is fast.

2. Molding frame adopt cast steel, when working the machine is more steady,and the transmission is gearbox, Gear box transmission, speed up fast, ensure that the molding is completed with the minimum force, and increase the service life of the equipment.

3. The basic frame with diagonal bracing inside,this makes it not deformed when the machine is transported and hoisting.

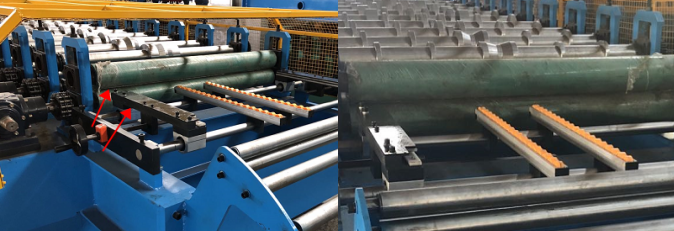

More details pictures of the machine

The plastic rubber roller at the feeding port can protect the paint surface from scratches and is convenient for feeding.

Packing list-sliding profile roll forming machine | ||||

No. | Name | Unit | Quantity | Remark |

Part 1 | 7 T decoiler with loading car | set | 1 | Automatic |

Part 2 | Main roll forming machine | set | 1 | Gear box drive |

Part 3 | PLC control station | set | 1 | Delta brand |

Part 4 | hydraulic system | set | 1 | For cutting |

Part 5 | Product automatic stacker | set | 1 | 6m length |

Overlooking picture of this machine