Light gauge steel machine drywall profile stud track roll forming machines

Drywall Profile Stud and Track Forming Machine is designed to produce non load-bearing partitions in galvanized steel. It has a wide range of applications, from small and residential needs to large commercial and industrial aplications. Using start-stop technology, these machines can make 8 profiles that make up all the basic metal frames for plasterboard walls and ceilings: three different with supporting stud and track (e.g. 48, 70 and 90mm), a ceiling profile (F530) and the relative wall angle.

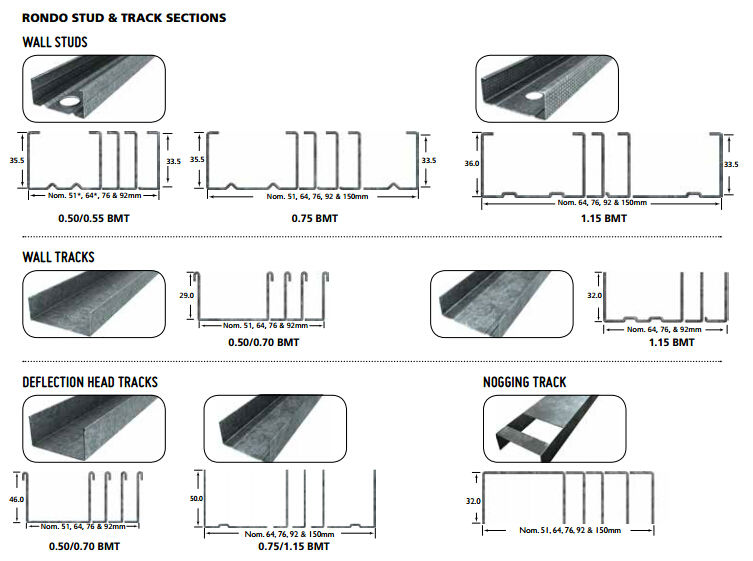

Here is metal stud and track drawings:

Machine produce the 60*27C shape and 28*27 U shape, this is one of the standard size for ceiling products.

This is the combined roll forming machine, the two working lines are independent.

We provide two sets transmission and control system.

Each line can make its own profile and cutting to different length. The profile is provided by you or us.

The feature of this design concept is that save the work space in the workshop and save some cost compared two sets machines.

The machine on the photo is the normal speed of 25m/min, we also can make the high speed one up to 60m/min. So you can choose the one which workable for you.

Details:

Parameter of Light gauge steel machine drywall profile stud track roll forming machines :

No. | Main parameter of | |

1 | Length of the main part | 3300*1000*1400mm |

2 | Weight of main part | 3.5 T |

3 | Voltage | 380V-50HZ-3P (as customer’s request) |

4 | Roller fixer | Guide column |

5 | Frame | Memorial arch frame type |

6 | Frame thickness | 25mm |

7 | Drive mode | Gear or chain |

8 | Material of rollers | 45# steel with tempering |

9 | Material of shafts | 45# steel with tempering |

10 | Diameter of shafts | φ40mm |

11 | Number of rollers | 10 rollers |

12 | Main power | 4kw (Cycloidal planetary gear speed reducer) |

Light gauge steel machine drywall profile stud track roll forming machines working videos for your reference: