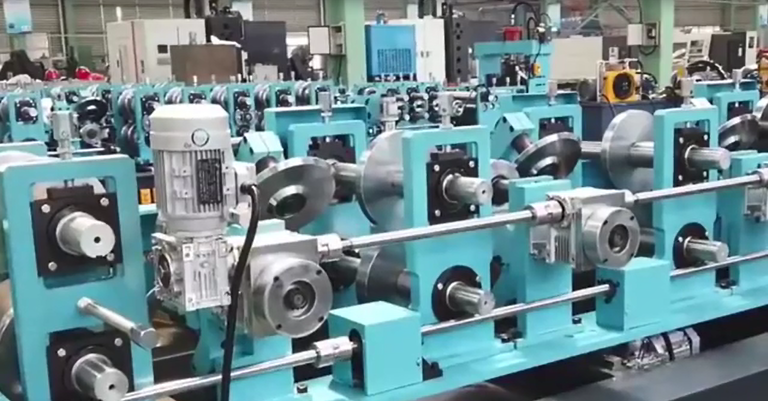

C/Z Purlin Roll Forming Machine

Purlins bear the loads from the roof deck or the sheathing materials, and they are supported by large rafters, building walls, steel beams, and other structures. When compared with rafters that are closely spaced, the application of purlins is quite prevalent in prefabricated metal construction systems, as well as in both the traditional post-and-beam construction techniques and the newer pole construction methods for framing.

Purlins transfer the roof loads to the major structural components that support the roof. The shape and layout of purlins are important design factors, which are determined by the magnitude of the roof loads and the maximum lengths of the sheets to be used. Ultimately, in the design of a concrete roof structure, it is essential to fully understand and comply with the local building codes.

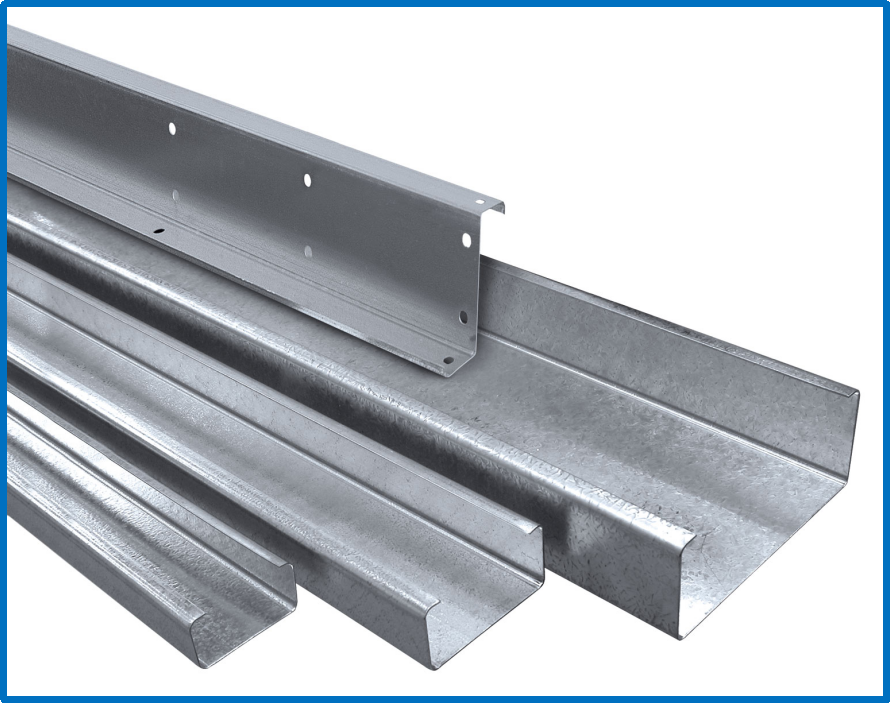

Bansal's C-section purlins offer a diverse range of thickness options. They can be manufactured precisely according to customers' exact specifications, with no limitation on length. This feature allows them to be easily adjusted to suit buildings of various scales.

Bansal also produces C-section purlins that are undrilled, as well as those with pre-drilled holes of different diameters. (Oval-shaped and round-shaped holes of any size can be provided upon request.) The web height of these purlins can reach up to 300 millimeters, and the thickness can be up to 3.2 millimeters.

Another type of Z purlins is sturdier than C purlins, and they are mostly used in combination at the joints and overlapping parts. Z purlins are horizontal beams that serve to form the roof and wall joists of a building's shell structure. Positioned between the roofing sheets and the building, they function as supports for the sheets, ensuring that the roofing sheets are firmly installed and secured in place. Thanks to the relatively high flexibility and lightweight characteristics of Z purlins, they are most frequently applied in agricultural and industrial buildings. This enables them to be easily adapted to buildings of various specifications.

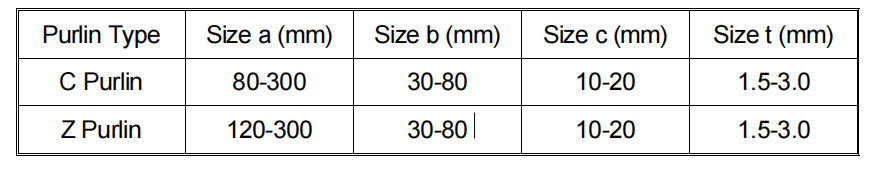

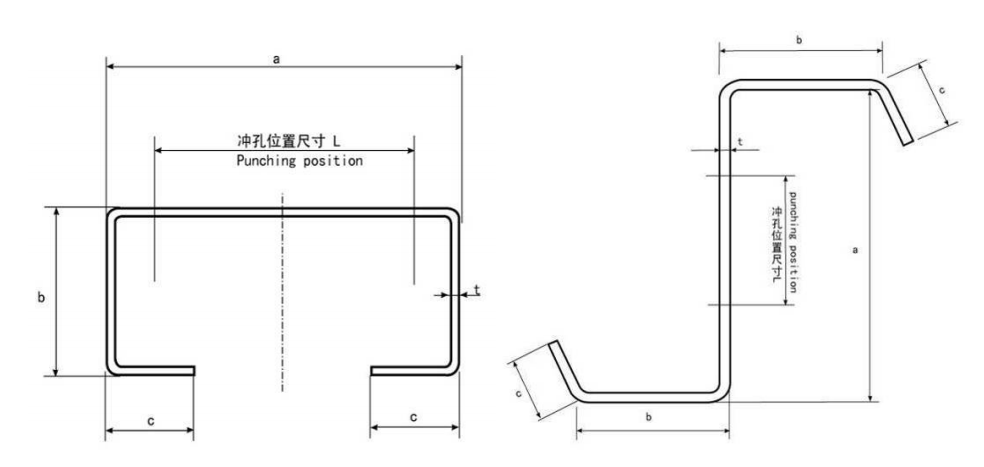

Here are Standard Purlin specifications

Different adjustment methods

Purlin Size adjustment

CZ transform adjustment

Application pictures of prulins structures

Size adjustment :

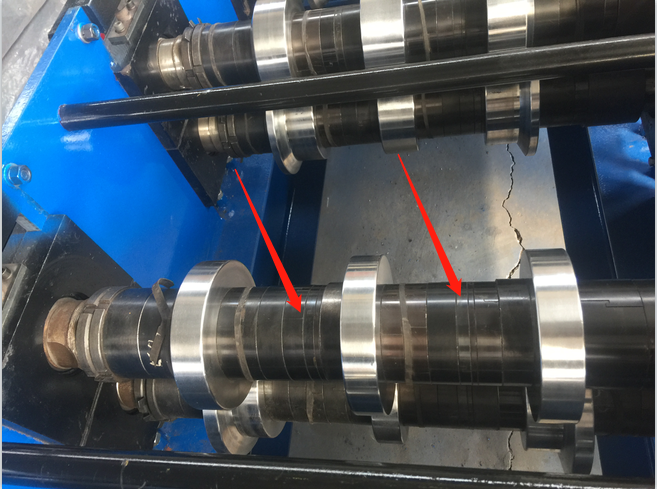

(1) Adjusting the spacers (manual)

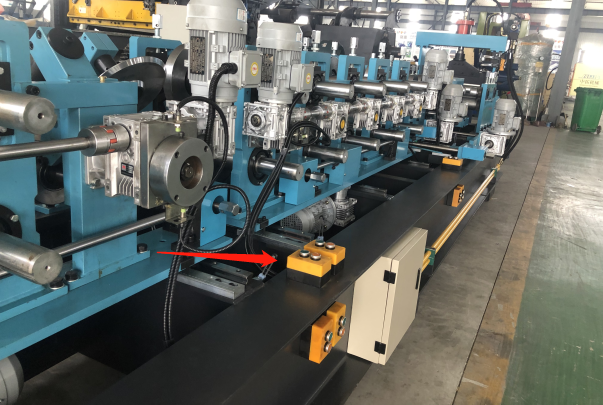

(2) Movable frame and shaft + Servo motor + scale , button touch (semi-automatic )

(3) Movable frame and shaft + Servo motor + Encoder , PLC control directly (Fully- automatic)

CZ transform adjustment :

(1) Adjusting by handrail (manual)

(2) Servo motor + button touch (semi-automatic )

(3) Servo motor + PLC control directly (Fully- automatic)

The greatest advantage of C/Z Purlin Machine Series

The greatest advantage of this series of machines is that you can use one machine to produce products of the same model but in different sizes, and you can also use the same machine to produce products of different models.

Meanwhile, there are various configurations available, which can well meet the production needs within the customers' budgets as well as the demands of the market.

More details about the C/Z Purlin Machine Series

The Standard - CZ prulin Machine has a specification of 13 m x 1.5 m x 1.7 m, weighs about 13 - 14 Tons and has a total power of 32.5 KW. The CZ transform adjustment is manual, while the Purlin Size adjustment is semi - automatic. It features an Arc frame and uses Chains for transmission, with a speed of 20m/min. There are 5 sets of Pre - punching unit. Both the Decoiler and the receiving process are manual, and the price of this machine is USD 45000.

For Configuration replacement, there are several options with their respective price differences. For holes punching per unit, it is USD 1500 more. Using a 3 - Ton hydraulic decoiler instead of a manual one costs USD 3800 more. Opting for gear boxes instead of chains incurs an additional cost of USD 6000. Using a servo motor instead of a normal motor adds USD 4000 to the price. Adding more plate cutting before leveling is priced at USD 1500 more. One - touch PLC fully automatic CZ change has a price difference of USD 5500 more, and a fully automatic package and receiving table is USD 14000 more.