Galvanized steel CD UD double line ceiling light steel roll forming machine

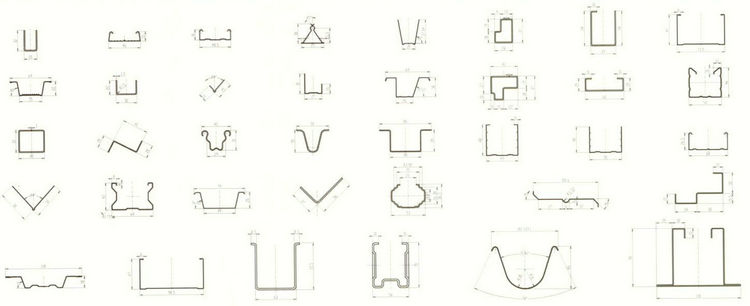

Light steel roll forming machine can make the product which is used for partition system and ceiling system.There are lot of product sizes according to the architectural feature in different countries or areas. We have summaried some regular sizes as below for ceiing system and partition system.

Some profiles can be made on one machine, means the machine is adjustable. We can provide different machine design concepts based on customers' requests.I will share some machine pictures with you:

The main elements of the light steel roll forming machine as below:

1. 1.5 ton vertical manual decoiler two sets

2. roll forming machine with two working lines

3. The transmission system is independent

4. Hydraulic cutting and PLC control are independent for each line as well

5. 3 meters long product receiving table two sets

The advantage of the double lines light steel roll forming machine:

1. All transmission system, cutting system and PLC control system are independent,

ensure the two lines can work separateply according to the production order.

2. We adopt the flying cutting system to improve the work speed

3. This machine is equal two sets machine, we use one basic frame.

It can save lot of working space and save some cost.

4. The normal working speed is 25m/min, even we can make it more faster till 60m/min or more,

depends on customers' requests.

The specification of the double line light steel roll forming machine

1. roller material: Cr12 with quenched treatment

2. rolling station number: 10-12 stations

3. Shaft material: 45# steel with tempering treatment

4. Shaft diameter: 40mm

5. driving motor power: 3+3 kw

6. hydraulic motor power: 3+3kw

7. structure: vertical arch frame

8. control system brand: Delta or as required

9. control panel language: English/Spanish/Arabic/French (as required)

9. Encoder brand: Omron

10. work speed: 25m/min or as required

11. voltage: 220/380/440V-50HZ-3Phase (depends on the local one)

1. We can give you the guarantee by money, you can take the machine first without balance and try the quality.Meanwhile, can help customer solve the fund issue.

2. Because the machine is customized, the customers will provide us the profile drawing by themselves.But some customers don't have such profile drawings, then we can recommend the model types according to the local market standard.

3. We can operate the machine with material before the customer put order if you come to my factory.

4. Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installtion and training will be more clear and easily.

5. We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.

6. The machine will be tested before shipment with coil, ensure everything is ready

7. We will be at your service always, our customres can get in touch with us anytime, even have the time difference.