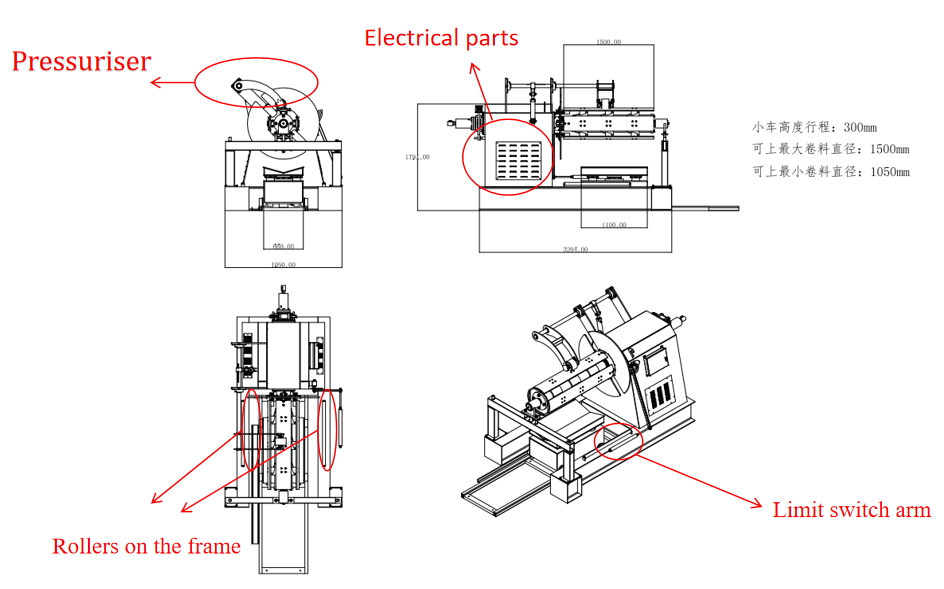

Hydraulic Decoiler

ZTRFM Hydraulic decoiler is used to unroll metal materials in rolls (e.g. steel plates, aluminum plates, etc.) from rolls and feed its into the tile forming machine for subsequent forming process.

During the material feeding process, the hydraulic unwinders are able to provide proper tension control of the material to ensure that the material is not overstretched or wrinkled during the molding process.

Automation: Hydraulic unwinders are usually coupled with the automation control system of the tile press molding machine, which can realize automatic loading, automatic unwinding and automatic adjustment to improve production efficiency.

ZTRFM hydraulic decoiler flow chat:

Hydraulic decoiler advantages

1. Improve efficiency:

the use of hydraulic decoiler can greatly reduce manual operation and improve the automation of the production line, thus increasing production efficiency.

2. Strong adaptability:

Hydraulic decoiler can adapt to different thicknesses and materials of the coil, a wide range of applications.

3. High stability:

Hydraulic decoiler adopts hydraulic system, which has better stability and reliability and ensures the smoothness of the production process.

4. Accurate tension control:

hydraulic decoiler can precisely control the tension of the material to ensure that the material will not be deformed or other quality problems in the molding process.

5. Simple operation:

the operation of hydraulic decoilers is usually simple and easy to start, reducing the difficulty of operation.

6. High safety:

Hydraulic Decoiler are designed with operator safety in mind, and usually have safety guards to reduce the occurrence of safety accidents.

Pneumatic braking system