This Automatic C Z two in one purlin roll forming machine is used to manufacture series of C and Z sections. The machine is mainly composed of uncoiler, flattening device, punching device, cutting equipment, roll forming machine, collection table, hydraulic station, and PLC control system, etc. It can produce 80 - 300mm wide C and Z purlins, height from 45 - 80mm. The raw material is cold rolled steel, galvanized steel, etc, material thickness is 1.5 - 3mm. Or if you need, we can make it to 4.0mm

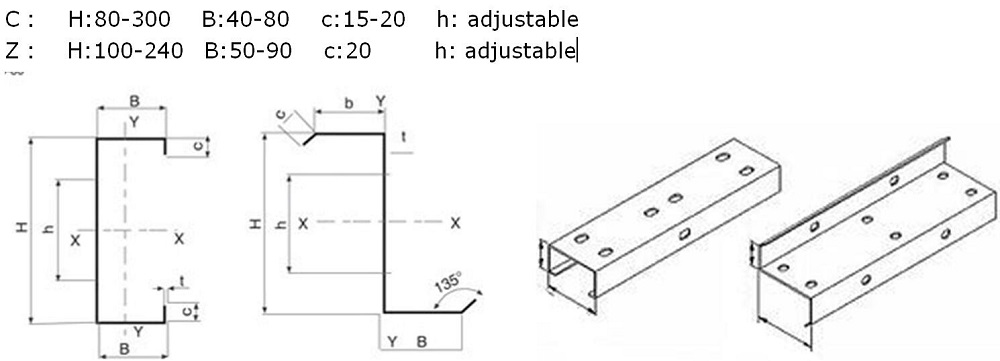

Here is drawing of all C Z purlin for your reference:

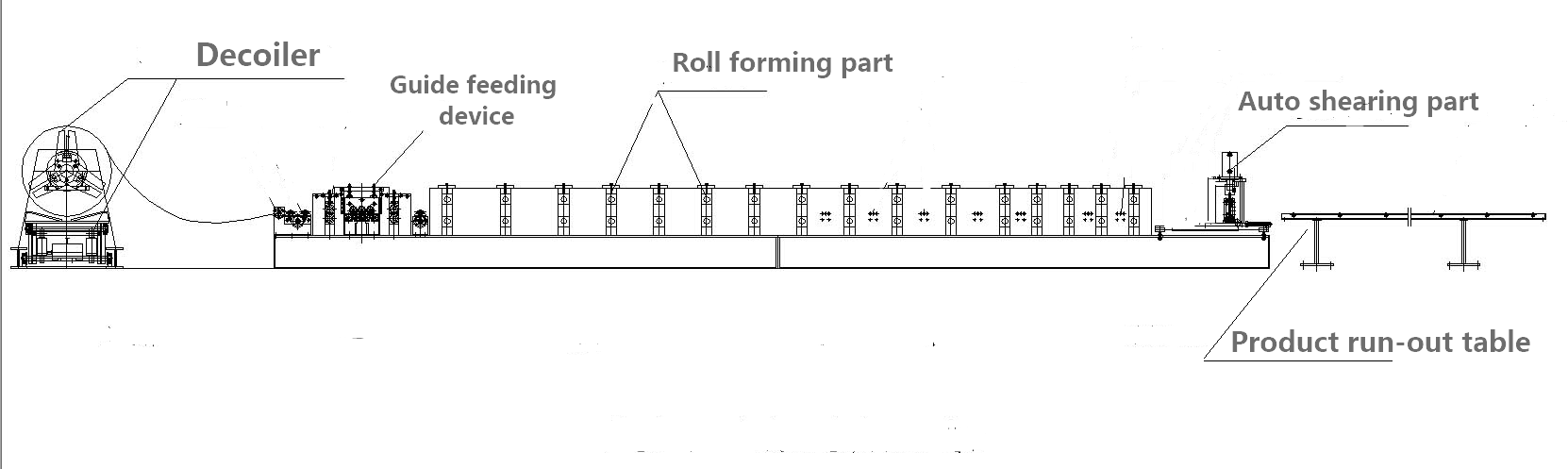

Work flow:Uncoiling→ Feeding material into machine →Roll forming →Punching part→Auto shearing part→Products receiving table

1.Main features of Automatic C Z two in one purlin roll forming machine:

The advantages of CZ purlin machine AUTOMATIC size-change type are as follows:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost.

4.Infinite sizing(any size within machine range),help to save material.

5.Optional Punch hole at any position of purlin web side and flange side.

Main parameters of Automatic C Z two in one purlin roll forming machine:

| 1 | Machine name | Automatic C Z two in one purlin roll forming machine |

| 2 | Dimension | 11000*1500*1700mm |

| 3 | Weight | 8T |

| 4 | Total power | 21KW |

| 6 | Voltage | 380V/50HZ/3PH |

| 7 | Material | GL/GI |

| 8 | Forming speed | 15m/min |

| 9 | Material thickness | 1.5-3.0mm |

| 10 | Tolerance | ±1mm |

Here the C purline and Z purline machine working video for your reference: