ZTRFM High speed corrugated roofing sheet machine

High speed corrugated roofing sheet machine brief introduction

High speed corrugated roofing sheet machine are also a type of roof tile forming machine. Their ripple-like appearance makes them popular with many customers. Corrugated roofing sheet are also a popular design in the construction industry. The machine boasts a production speed of up to 40 m/min. It utilizes a gearbox drive (achieving a stable 1:1 ratio) and servo-driven cutting (enabling non-stop cutting and improving production efficiency), enabling fully automated production.

High speed corrugated roofing sheet machine is also equipped with a hydraulic decoiler with a trolley, eliminating the difficulties encountered when installing and unwinding steel coils in customer facilities without a trolley. The hydraulic trolley can carry the steel coil horizontally, as well as ascend and descend to assist in loading it onto the hydraulic uncoiler.

For the finished sheet material handling area, we also have a conveyor and palletizer. The conveyor slows down the production of finished roof tiles, while the automatic palletizer neatly arranges and stacks the sheets. Workers only need to periodically remove the finished products, significantly saving manpower.

High speed corrugated roofing sheet machine advantages

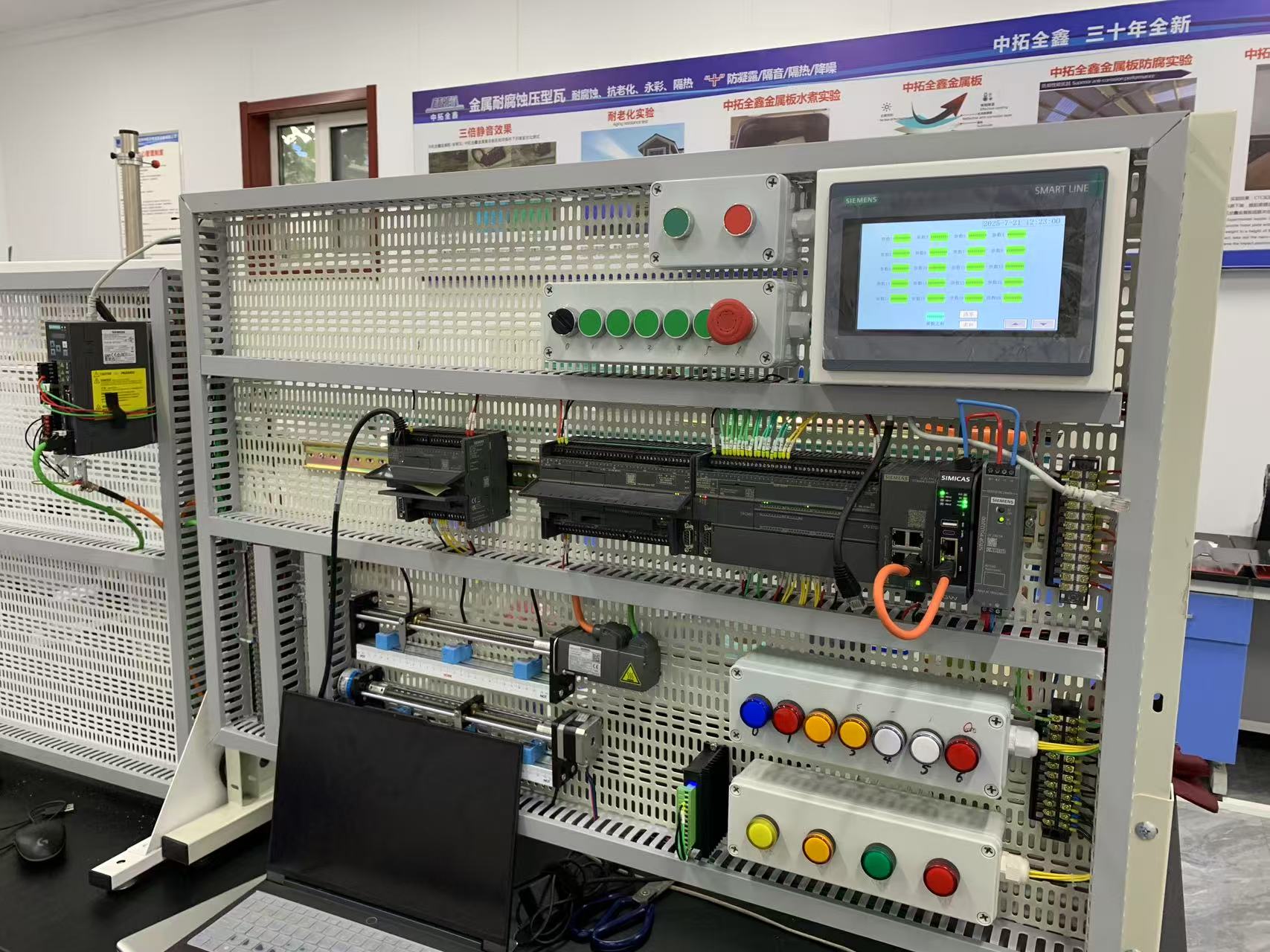

1. Highly Automated: Our corrugated roofing sheet roll forming machine's electronic control system uses imported Delta/Siemens brands. Production speed, finished product length, and production quantity can be set directly from the control unit, and remote control and debugging are supported.

2. Better Quality and Durability: Our corrugated roof tile make machine's rollers and shafts are connected and secured using keys and keyways. The shafts are made of 45# steel, which has been high-temperature quenched, and the rollers are chrome-plated, achieving a higher level of hardness.

3. High Efficiency and Fast Profit: Based on customer feedback, our standard-speed machine can earn back its investment in finished roof tiles in approximately six months.

4. Perfect Details: ZTRFM corrugated roofing sheet make machine frame is welded, polished, and then repainted three times to ensure effective paint adhesion and a more refined appearance.

High speed corrugated roofing sheet machine Technical parameters

Part 1. Hydraulic decoiler with loading car

Hydraulic decoiler

A. Supporting the coils and doing uncoiling. The capacity is 10 Tons(max).

B. It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter of coils. It is equipped with the cantilever.

C. Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.

D. The core can ensure the expand range φ450 of the coils inner diameter. It will provide the rubber band to ensure the 550 mm diameter.

Carrying capacity: 5 tons

Max coil width: 1250 mm

Feeding speed: 0-40 m/min (adjustable)

Driving motor power: 7.5 kw

Hydraulic motor power: 3 kw

Structure: welding by the steel plates and profiled bar.

Remark:The speed sensor of the decoiler enables the decoiler to adjust the speed to match up the production of the roll forming machine automatically.

Hydraulic entry loading car

A. The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler.

B. It is driven vertically by hydraulic cylinder with 4 guide pillars

C. The level movement is driven by motor

D. Capacity:5 T

E. Driving motor power: 7.5 kw

Function: It is used to lift up and down, move forward and back to make it easy to load the coils on decoiler. Hydraulic controls lifting, motor drives moving. The car is controlled on the auxiliary control panel. Its moving speed is 40 m/min. When the coils on decoiler, the car will return back to the start position. It can also carry back the unfinished coils from decoiler.

Part 2.Main roll forming machine

Main roll forming machine | |

Machine frame | Cast iron archway ,high precision and better stability |

Material of rollers

| High grade 45# forged steel |

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Forming stations

| Roller stations :22 rows |

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

Diameter of shafts | Φ80mm solid |

Material of shafts | High grade 45#,with heat treatment |

Forming speed | 40 m/min |

voltage | 480V/60HZ/3P (as requested) |

Transmission way | Gear box transmission(bevel gear inside) Advantage: can improve the speed directly after cutting |

Main motor | 11 KW |

Cutting blade material | Gcr12 quenched treatment |

Cutting type | Servo cutting system |

Part 3: PLC control system with transistor to Faster acceleration

Control system PLC brand:Delta/Siemens

Frequency brand: Delta

Counter brand :Omron

Screen type: Touch screen & buttons

Screen language: English/Chinese/as request

Brand: Siemens

Low pressure electrical part :Schneider

Part 4: Currguated roof tiles cutting system with energy than and servo motor

Type of cutting: Hydraulic cutting

Driving method. By pillar type Cylinder, same with the one on the high speed corrugated roofing sheet roll forming machine

Hydraulic motor power: 11kw

Cutter material : GB-Cr12

Cutting length tolerance: ±1 mm

Cutting feature: Steady and safe working condition and low sounds

Oil tube and wires connection; All the tubes and wires will be marked by the numbers or letters,So that it will be very easy to connect for the new.

Part 5: Product autoatic stacker

1. Auto stakcer for reception of the cut profiles: allows free unloading of each cut profile and automatic placement on the stack of previously made products,

2. Stacking principle: the top sheet will not damage the sheet below, the profile of the sheet below will match the profile of the top sheet;

3. Unloading of the finished products (moving of the stack of finished products from the high speed corrugated roofing sheet machine production line): mechanic, it will be possible to pick the stack using a fork-lift or in a similar manner (fork-lift will be provided by customer).