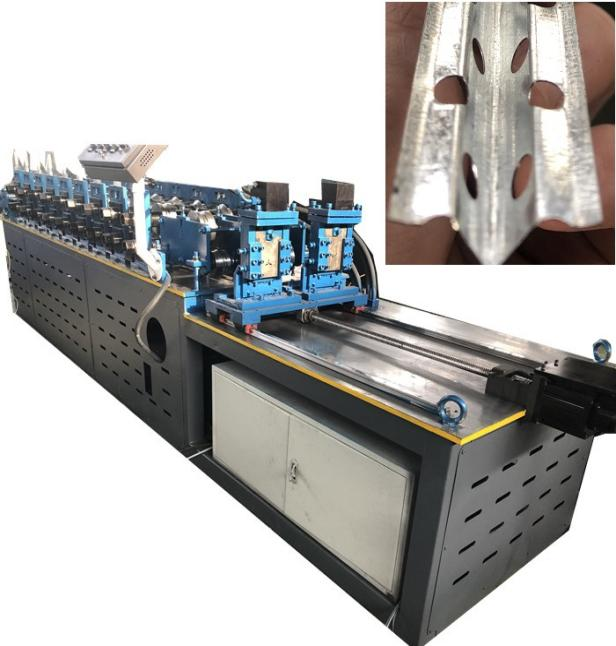

Double u track and stud rollformer drywall system cd ud double line machine

Introduction of Double u track and stud roll former

The finished galvanised steel C stud, U track, channel, v angle, furring panels made by our light keel sheets roll forming machines offer builders a competitive alternative to traditional wood trusses. The advantages of this roll forming machine are realizing material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling. This machine provides significant improvements over other light gauge steel trusses currently available. Flexibility and design advantages allow architects, engineers, contractors and owners' exceptional versatility and performance characteristics not available with any other type of truss material.

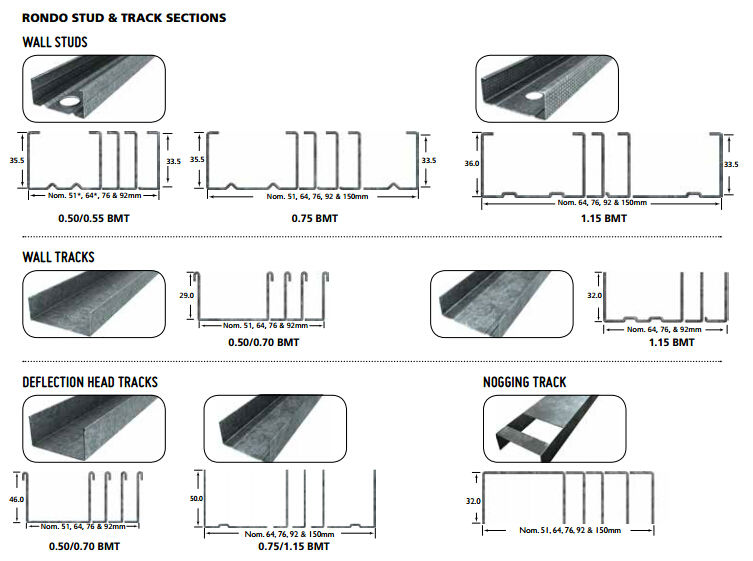

Here are some popular u track and stud drawing profiles for your reference:

Machine produce the 60*27C shape and 28*27 U shape, this is one of the standard size for ceiling products.This is the combined roll forming machine, the two working lines are independent.We provide two sets transmission and control system. Each line can make its own profile and cutting to different length. The profile is provided by you or us.The feature of this design concept is that save the work space in the workshop and save some cost compared two sets machines.The machine on the photo is the normal speed of 25m/min, we also can make the high speed one up to 60m/min. So you can choose the one which workable for you.

Components of production line

No. | Name | Unit | Qty |

1 | 1.5T Manual decoiler | set | 1 |

2 | Main forming machine | set | 1 |

3 | LC control system | set | 1 |

4 | Hydraulic pump station | set | 1 |

5 | Post cut | set | 1 |

6 | Electric motor | set | 1 |

7 | Output table | set | 1 |

We have more options and design of the machine for your reference:

ZT Machinery is a professional machine manufacturer, for drywall production now we can give following options for your reference:

Option A: One machine for all profiles 50-75-100 CU 6 profiles, manual adjustment by spacer.

Option B: One machine for all profiles 50-75-100 CU 6 profiles, automatic adjustment by PLC.

Option C: High speed like 35m/min, 80m/min, that is optional

Option D: Combined stud and track machine by two machins, one is for C and one is for U, for easy manual adjustment.

For detail option, please refer to following pages.

Here is combined stud and track machine working videos for your reference: