Description: Automatic stud and track rolling forming machine is designed to make the stud and track in batch fully automatic of sizes changing. The speed is optional from 25 to 125 meter per minute. High speed and normal speed stud and track machine.

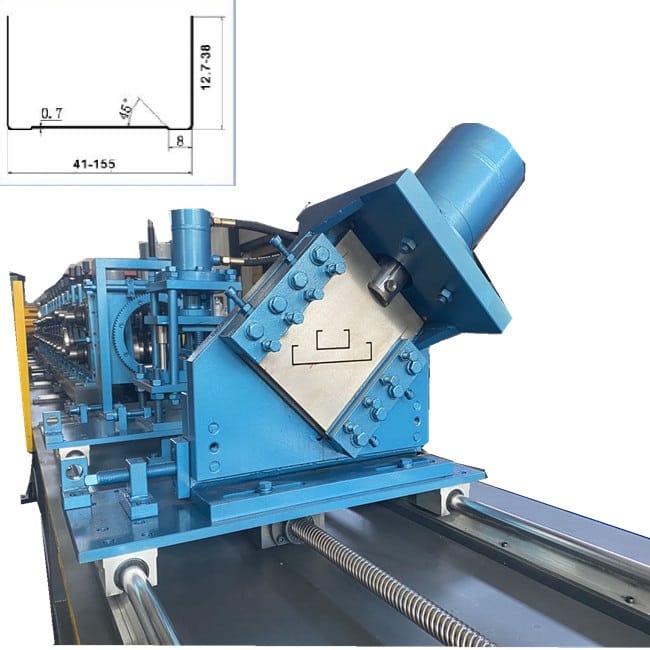

Automatic stud and track rolling forming machine is designed to make the stud and track in batch fully automatic of sizes changing. The speed is optional from 25 to 125 meter per minute. High speed and normal speed stud and track machine. Steel Stud Drywall Framing System provides a durable, practical and lightweight structure for internal plasterboard walls and for specific external walls. The availability of various sizes, complimentary components such as nogging tracks, curved tracks and special cleats ensure Rondo Stud and Track wall systems are available to suit almost all situations. Here we will take some drawing profile for your reference:

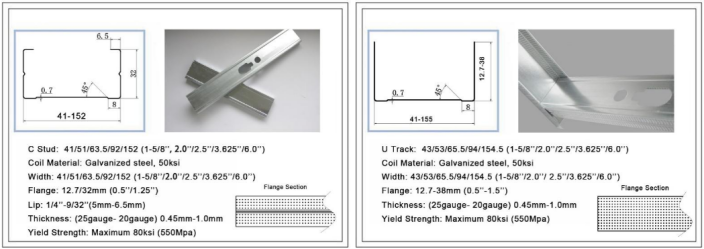

For example, it can support the following sizes:

Stud:

Sizes: C41/63.5/92/102/152 (1-5/8’’, 2.0’/2.5’’/3.625’’/6.0’’)

Material :GI Coil

Bottom width :(1-5/8’’, 2.0’’/2.5’’/3.625’’/6.0’’)

Web flange:32mm(0.5’’/1.25’’)

Lip sizes: 5-6.5mm (1/4’’ – 9/32’’)

Track

Size:U43/65.5/92/102/154(1-5/8’’,2.0’’/2.5’’/3.625’’/6.0’’)

Material :GI Coil

Bottom width:(1-5/8’’, 2.0’’/2.5’’/3.625’’/6.0’’)

Web flange:12.7/32mm/75mm

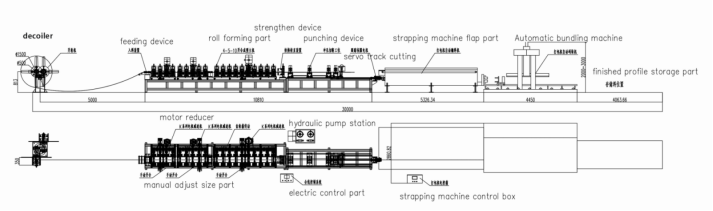

Work flow for automatic stud & track machine:

Automatic stud and track rolling forming machine features:

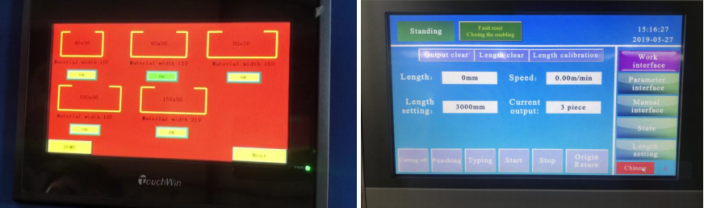

1. Sizes are adjusted by PLC fully automatically. The shaft with rollers are movable.

2. Handrail at the leveling part with guiding system, for feeding coil easily.

3. With oil drops to cool the roller and make it durable and use for a long time.

4. Gearbox transmission to make sure fast speed. For our machine the speed could be adjusted from 25 to 120 meter per minute.

5. Separated rollers for sizes adjustments.

1. Use two motors for main transmission system to give the power evenly.

2. Use servo motor for tracking shearing.

3. Use energy tank for non-stop punching and shearing. By this way, the shearing is more beautiful no bur.

4. With the adjustable embossing rollers and ribs, you can make them according to your own design.

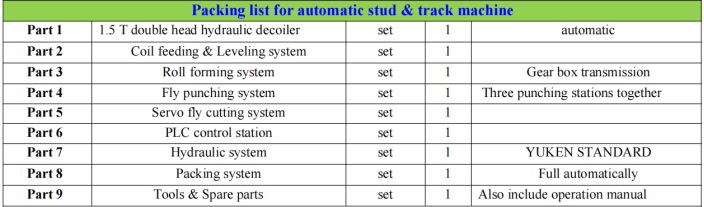

For the part:

Normally speaking, the high speed stud and tack rolling forming machine speed will be delayed by the punching system. Different with others, we use the non-stop punching, by this way, no matter how many types you want to punch, we still can reach the speed of 70 to 120 meter per minute.

About the package system:

When the machine working in high speed, the workers are hard to do the collection of the stud and track. Then you can choose the automatic package system, it can help you package the profiles orderly and then package them well for loading.

Here is the Automatic stud and track rolling forming machine working videos for your reference: