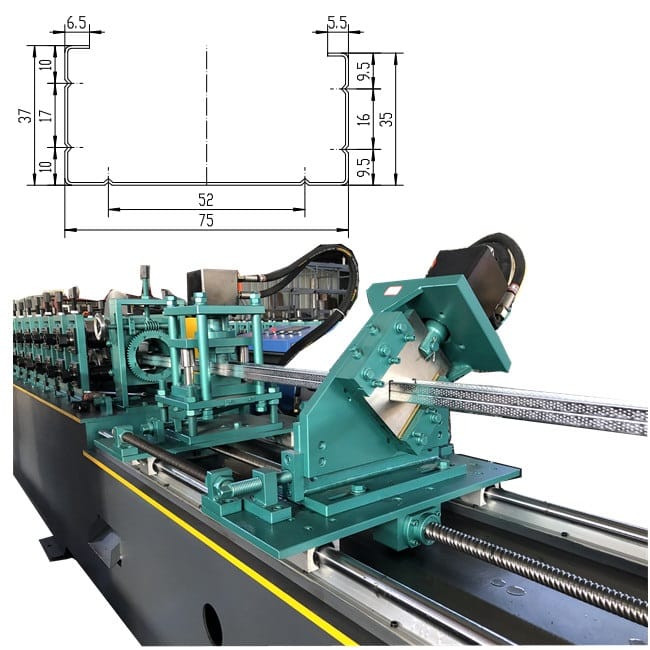

Metal profile stud rolling forming machine

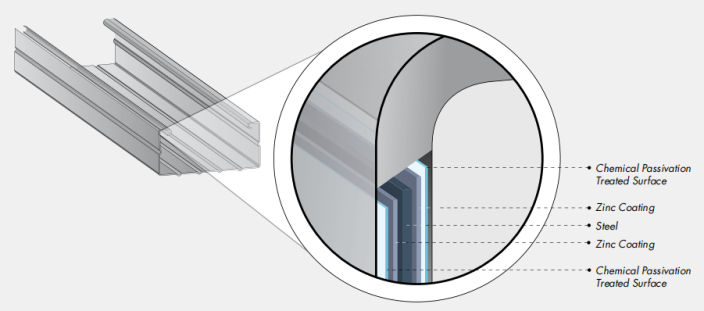

Metal profile stud rolling forming machine is designed to make the metal profiles in batch fully automatically. Metal profiles are precision-engineered, high-quality steel sections that are used to form the metal substructure of the Drywall or ceiling Systems. All metal sections produced from high-grade hot dip galvanized steel coils with the cold rolled forming process by the rolling forming machine. Here we will take some random drawing to show you how the metal profile rolling forming machine is designed.

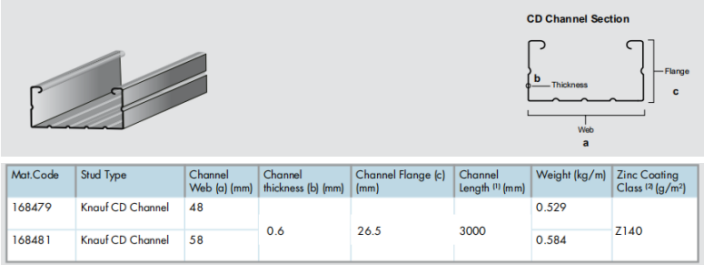

Sturdy 0.6 mm sections with full set of compatible accessories

Part of a complete ceiling system

Only one type of channel for main and furring functions

Increased web width for faster/easier installations and smoother joints

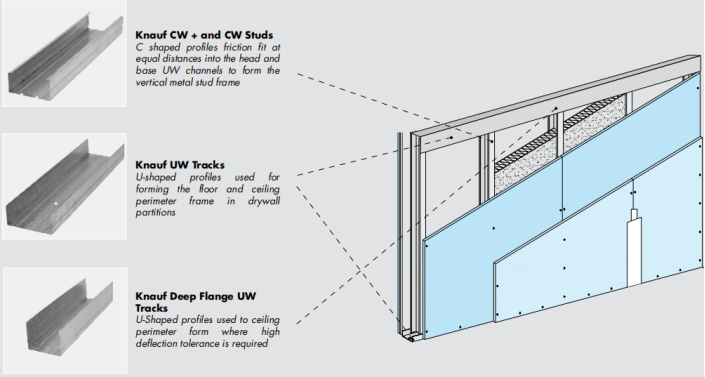

Where to use of those profiles:

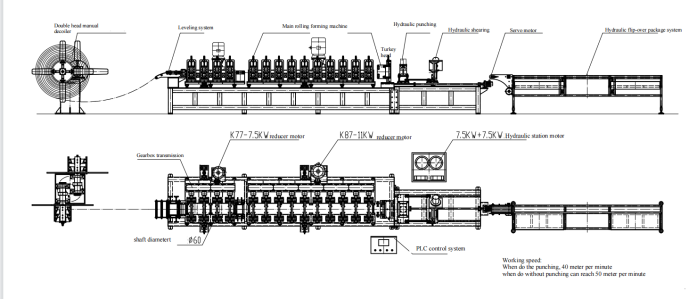

Metal profile stud rolling forming machine

Metal profile stud rolling forming machine parameters and options for your reference.

1. We have the following speed options for your reference:

Normally 25 to 35 meter per minute without punching

High speed is from 50 to 75 meter per minute with punching

Highest speed now we can reach 120 meter per minute with punching.

2. Adjustment options.

We have manual adjustment by spacer.

We have PLC control fully automatic type.

The machine working flow like this:

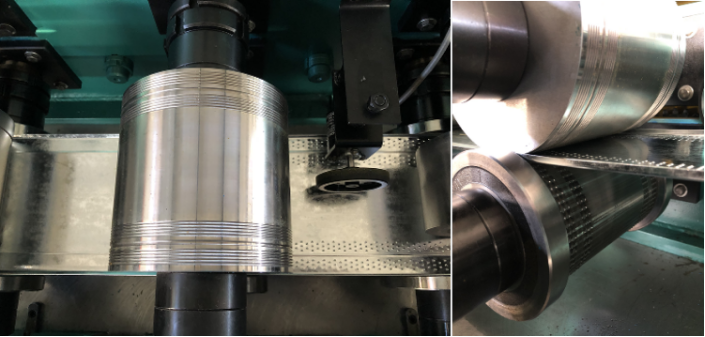

Note: We use split rollers to realize one machine to produce C products with different bottom widths. | |

Voltage | 380V ,50Hz, 3Phase (as customer request) |

Frame type | Memorial arch frame of thickness 30mm |

Drive mode | Heavy duty gearbox as transmission |

Material of rollers | GCr12mov |

Material of shafts | 45# steel with tempering |

Diameter of shafts | Φ70mm |

Number of rollers | 15 rollers With more rib roller one more station |

Main power | 7.5 kw and with one more motors 11kw |

Raw Materials of the steel coil | Galvanized steel plate |

Material thickness | 0.5-1.5 mm |

Forming speed | 50 m per minute without punching hole |

The following we share the manual adjustment machine. The advantages of it, that manual adjustment cost is more lower and if you have the engineers who are professional for machines, manual adjustment will be best options.

If you need to add the punching or the embossing, we can also add for you. We can design the dotting embossing or various types holes either non-stop or stop punching.