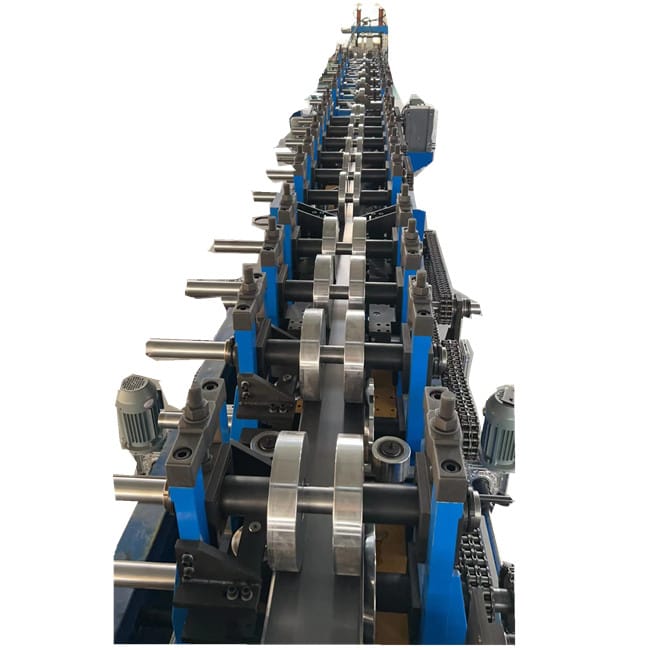

C purline machine, Z purline machine, CZ purline machine

Description: C purline machine, Z purline machine, CZ purline machine more options for you to choose.

Since July 2009 no limit shearing system has been developed, it has been equipped with CZ equipment and make it more flexible .Today CZ series is industrial rolling forming machine and make lots of frame for warehouses and other buildings. It has been formed large-scale, multi-series and multi-category equipment supply. In recent years, ZHONGTUO has been engaged in software and industrial control. The technology in the field is also gradually embedded in engineering and construction products series, realizing high-precision and high-speed servo control industrial computer operation, remote data interaction line programming and other typhoon level breakthroughs.

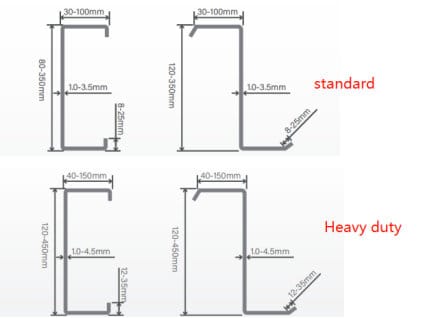

We have lots series for your reference. For example, standard CZ. Heavy duty and big scale CZ purline like picture 2. Please according to the sizes and supported material thickness to choose the proper mode rolling forming machines.

To make sure more easy to choose, we make CZ purline machine, C purline machine and Z purline machine in the following mode:

Mode 1: C purline rolling forming machine MC、LS(LS21、LS31) MC 1. The forming and shearing method is punching and shearing after forming 2. Production specification C width (50~250) mm; Small side (8~20) mm and small side ≤ 0.39 * waist height; Waist height (25~60) mm and waist height ≤ 1.4 * (bottom width - small side - 21); 3. The plate thickness t (1.0~2.5) mm is adjustable; Q195/q235 plate thickness to 2.5mm under normal pressure, q345/355 manganese high-strength plate to 2.0mm under normal pressure and occasionally to 2.5mm 4. Standard configuration: one group of single hole and one group of double holes | Mode 2: C purline rolling forming machine LS75-300(LS21/LS31) 1. LS21 punching shearing mode is punching shearing after forming, LS31 punching shearing before forming+shearing after forming 2. C width (75~300) mm; Small side (8~20) mm and small side ≤ 0.37 * waist height; Waist height (30~80) mm and waist height ≤ bottom width - small side - 20; 3. The plate thickness t (1.0~3.0) mm is adjustable; Q195/q235 plate thickness to 3mm under normal pressure, q345/355 manganese high-strength plate to 2.5mm under normal pressure occasionally to 3.0mm 4. Standard configuration: one group of single hole and one group of double holes |

CZ integrated rolling forming machine SX series (SX10, SX20) SX10 is post-forming punching shear, SX20 is pre-forming punching shear+post-forming shear 1. C width (75~300) mm, Z width (120~300 mm); Small side (8~20) mm and small side ≤ 0.8 * (waist height - 20); Waist height (30~80) mm and waist height ≤ 1.2 * (bottom width - small side - 30); 2. The plate thickness t (1.0~3.0) mm is adjustable; Q195/q235 plate thickness to 3mm under normal pressure, q345/355 manganese high-strength plate to 2.5mm under normal pressure occasionally to 3.0mm 3. A group of single holes and a group of double holes are equipped as standard SX series version (traditional hydraulic motor version (22KW), traditional ordinary motor version (18.5KW+11KW), intelligent version (servo motor 22KW+11KW)) | CZ integrated rolling forming machine LN series (heavy duty type) Punching and shearing before forming+shearing after forming 1. C width (80~300) mm, Z width (120~300 mm); Small side (8~20) mm and small side ≤ 0.8 * (waist height - 20); Waist height (30~100) mm and waist height ≤ 1.2 * (bottom width - small side - 30); 2. The plate thickness t (1.0~3.0) mm is adjustable; Q195, q235, q345/355 can be pressed to 3.0mm in normal time 3. One set of single hole and two sets of double holes are equipped as standard LN series version (traditional hydraulic motor version (22KW), traditional ordinary motor version (22KW+11KW), intelligent version (servo motor 30KW+11KW)) |

Why choose Zhongtuo C purline machine, Z purline machine, CZ purline machine:

1.Stepless rapid type change roller forming equipment | motor | servo motor | hydraulic pressure

2. Strong upgrading of professional performance

3. N series breaks through conventional specifications in purlin production,

4. With multi-version models, it has fast board output and stable output power,

5. High precision type change, high durability and other characteristics can meet your production needs under different conditions.

6.Higher accuracy of double alignment 10-roll CZ special two-axial alignment+four-roll two-axial alignment double-alignment system, easily improve the accuracy of C-type and Z-type.

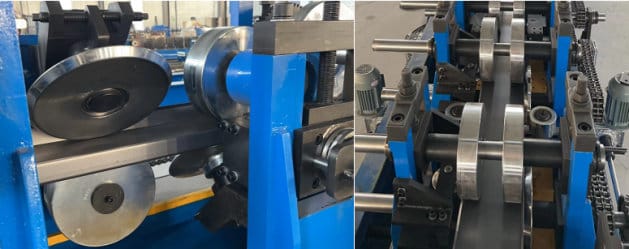

In the punching part, our frame of punching die holder much more strong, and also the oil pipe, we use high pressure type .

Strong in rollers design but with Conical design, in this way, it can make sure more beautiful but more strong when using.

Zhongtuo C purline machine, Z purline machine, CZ purline machine

In the punching part, our frame of punching die holder much more strong, and also the oil pipe, we use high pressure type .

Strong in rollers design but with Conical design, in this way, it can make sure more beautiful but more strong when using.

Here is one CZ purline machine working videos for your reference: