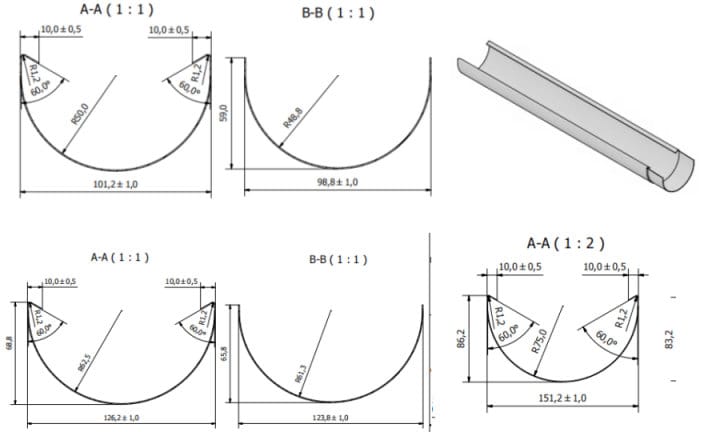

Description: Half round gutters rolling forming machine is designed to make the half round gutters by rolling forming machine principles in batch fully automatically.

Half round gutters get their name because of their shape. There are 2 types of half-round gutters:

European Bead / Traditional Single Bead – This was the standard, and is the old fashioned way to make gutters. The front bead curls out (a manual process), while the back of the gutter features an open hem. This gutter is commonly sold in copper or zinc.

Double Bead Half Round Gutters – The old fashioned way to make half round gutters, with the curled bead in the front and back side of the gutter. Manufacturing can be done in up to 19.5′ lengths. This gutter can be secured / installed via double bead hangers with rods.

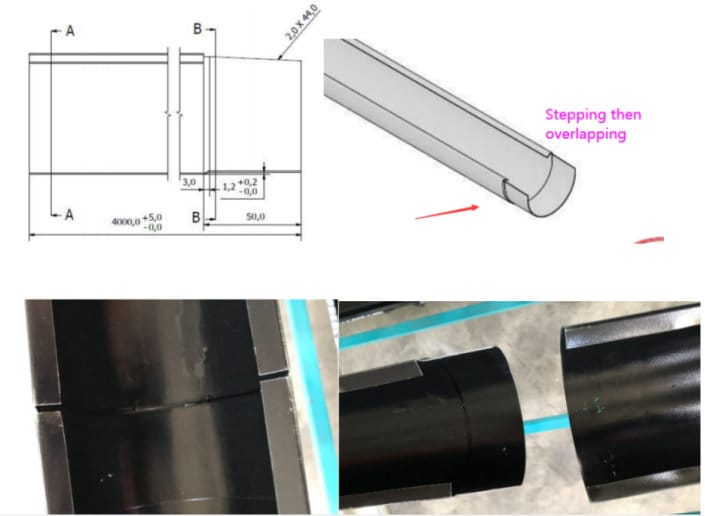

Reverse Bead Gutter – The new industry standard. Reverse single bead gutters allow for more economical materials, such as aluminum or steel to be used. This is due to the front bead curling in, and not revealing the other side of the metal, which is normally not finished. Here are some drawing profiles for your reference. Also for installation easily and overlapping easily, here are also some designs:

Note: all above sizes we made by one machine by fasting changing type. For the gutter machine the most important is that confirm the material, as the material is different and then the machine design will be different.

This is the traditional half round gutter, when do the overlapping, it has some problems. Now we have some new ideas like this:

Half round gutters rolling forming machine:

Half round gutters rolling forming machine design ideas:

1. About the accuracy control:

1) The shortest cut length is 100mm, and the longest cut length is 6000mm

2) Length error range: -0/+1 mm

3) Straightness deviation of water tank: 1mm/1m

4) Sink width error: ± 1 mm

5) Small bending width: 0.1mm/1m

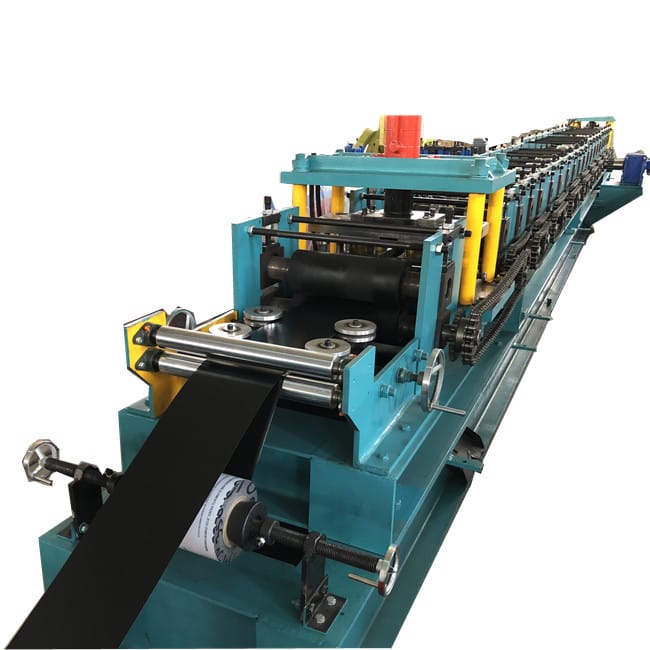

2.About the machine working flow:

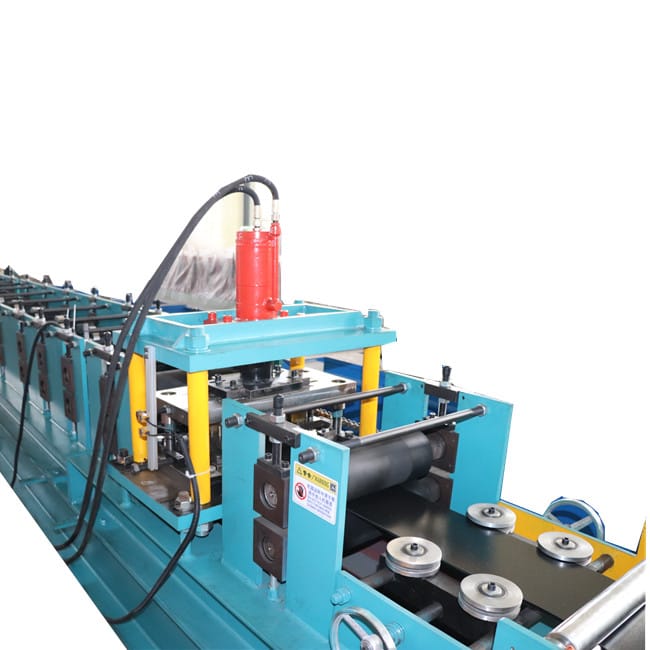

The equipment consists of the following parts: a 3-ton mechanical discharge rack, a guide device, a punching device, a forming system, a cutting (closing) system, a support device, a hydraulic system, and an electrical control system.

3.About the detail parameters of Half round gutters rolling forming machine

Plate specification and material: color steel coil; Strength: 235Mpa; Thickness: 0.3-0.7mm; Width: mm

Forming speed: 0-25m/min Adjustable

Power requirement: Main motor power: 7.5 KW (gear reducer)

Hydraulic motor power: 4KW (with air cooling)

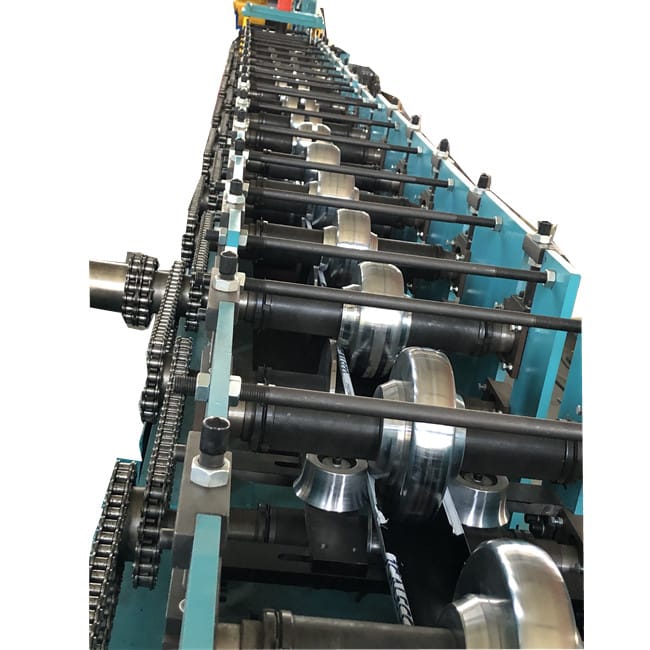

Host structure wall panel (blackened surface treatment, bolted frame connection) chain (single row 1-inch chain) structure, H350 steel base frame, with 200mm foot height

Cutting method: stop cutting

18 to 20 forming passes,

Control system Yaskawa frequency converter, Siemens PLC, Siemens touch screen (cantilever) (control cabinet is a separate type of machine tool that only displays English and Chinese)

Cutting method: fixed length cutting after forming

Power supply requirement 380V/50Hz/3Phase

Safety protection chains, gears, and other transmission parts are enclosed in a 1.0-mm thick box plate shape as a whole