Width Adjustable Metal U Channel Steel Lining Profile Roll Forming Machine

What is the function of steel lining? What are the situations where steel lining must be installed?

1. Doors and windows in buildings must withstand environmental influences, mainly wind pressure and rain and snow invasion, as well as the switching force and self gravity during use.

2. Wind force is the main cause of bending and deformation of door and window components (such as horizontal bars, mullions, and window frames), as well as frames and sashes. The safety of doors and windows mainly depends on their ability to withstand wind force, usually measured by the gas pressure value they bear per unit area.

3. The mechanical properties of hard PVC plastic are far inferior to those of steel, aluminum, and wood, especially the bending strength of hard PVC plastic is only 1/4 of that of wood, 1/28 of that of aluminum, and 1/84 of that of steel. Under the same cross-sectional shape and size as aluminum and steel profiles, the bending performance of hard PVC plastic profiles is much worse.

4. To compensate for this disadvantage, the cross-sectional dimensions of the hard PVC profiles used for making doors and windows are designed to be larger than those of steel and aluminum door and window profiles.

5. At the same time, the mechanical properties of its cross-sectional shape should be as reasonable as possible to meet the stress conditions of doors and windows.

6. The above methods cannot fully meet the mechanical performance requirements of doors and windows.

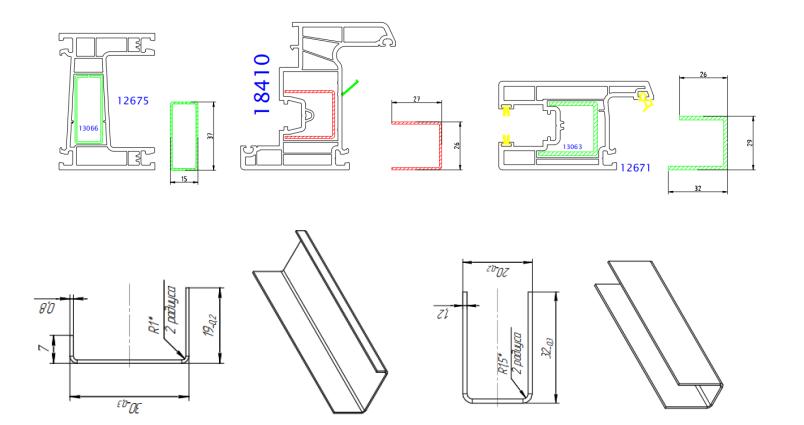

7. Another important measure is to add steel reinforced steel, also known as steel lining, to the cavity of PVC plastic profiles when a single profile of doors and windows exceeds a certain length.

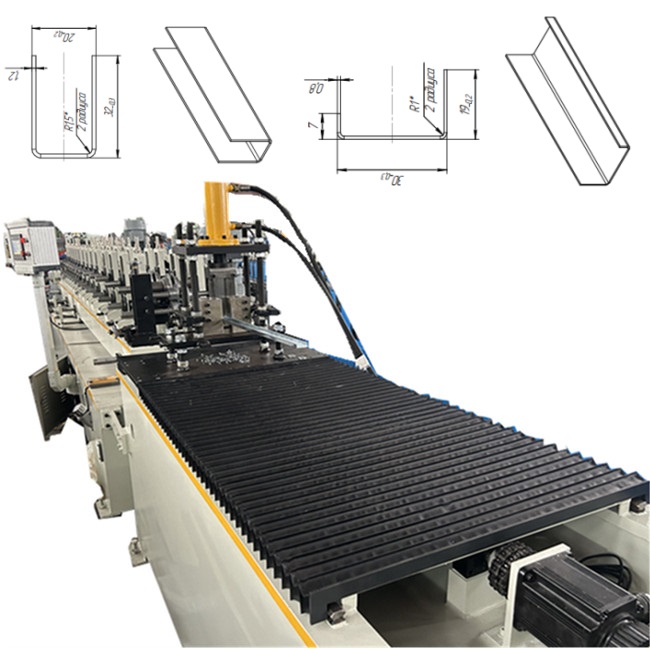

Here are some metal U channel steel lining profile sizes and drawing profile for your reference:

Width adjustable metal U channel steel lining profile roll forming machine

Features of Width adjustable metal U channel steel lining profile roll forming machine:

1. Bottom sizes adjust range from 10 to 40mm

2. Height adjustable from 5 to 40mm or more by adjusting the input coil width.

3. PLC control for sizes changing.

4. Speed Max to 45 meter per minute.

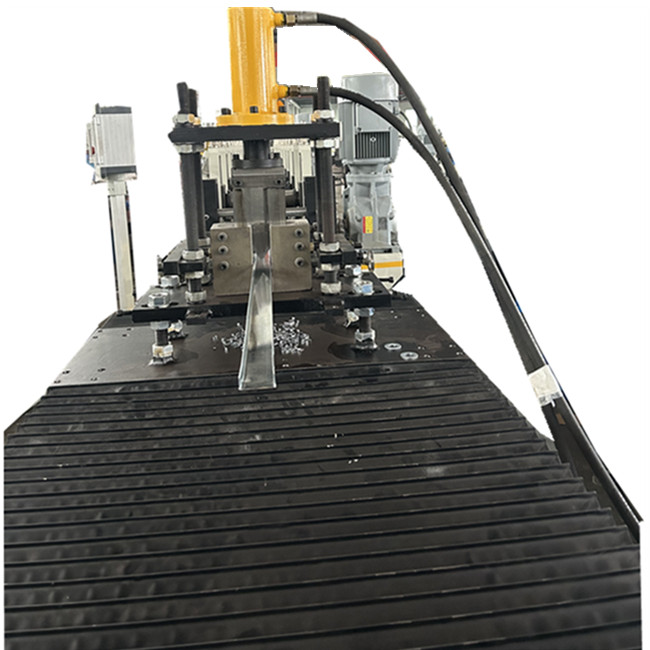

5. Servo tracking shearing system.

6. Rolling Product Rolling Strip Thickness: 0.8-1.2mm

Usage: The cold bending forming machine is used to cold bend the sheet metal to the desired profile.

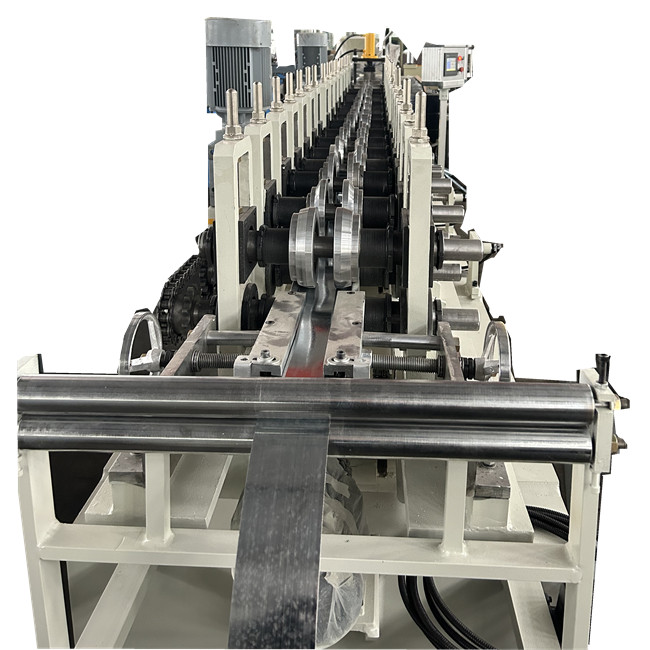

Function and structure: The sheet metal is gradually transformed into the bottom plate required by the drawing by rolling through a 9-component mold.

The roller adopts Gcr15, which is CNC processed after overall quenching, and the hardness can reach HRC56-62 °

Processing technology: rough machining, heat treatment, precision machining, hard chromium plating

Main frame: 8mm thick steel plate welding, pig iron memorial archway, chain drive.

The memorial archway is 170 memorial archway.

Roller shaft diameter: 70mm Material: 45 # steel

Processing technology: quenching and tempering treatment, rough processing, precision processing

Main drive motor: 15kw

Here is the Width adjustable metal U channel steel lining profile roll forming machine

working videos for your reference.

By this video you can learn the following information:

1. How the speed it can work to.

2. How is the sizes change by PLC from the Min to the Max.

But for more detail information, you can contact me at any time.