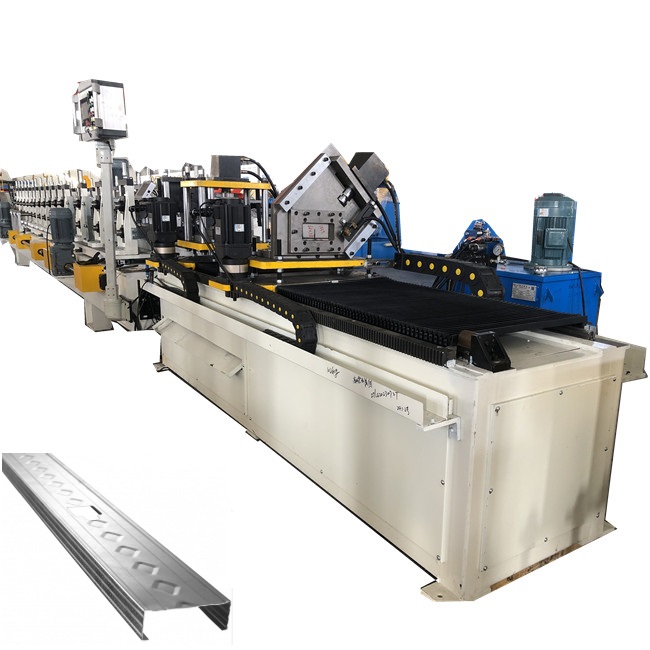

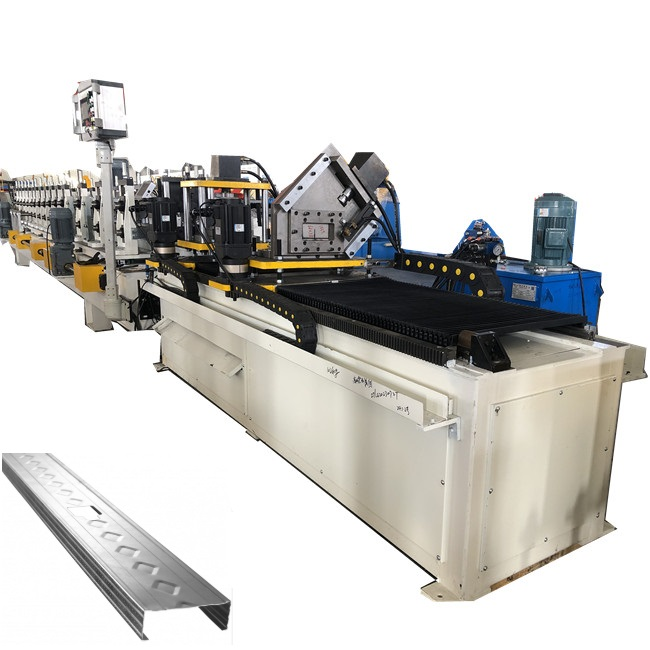

High speed automatic seismic drift track machine rolling forming machine

Description:C Stud&U Track Roll Forming Machine,100% made in China,is to fully produce automatically the production of C Stud and U Tack with options for punching holes and embossing customer logos their main advantages are stable operation with a strong body frame and customized designs.

High speed automatic seismic drift track machine rolling forming machine

C Stud&U Track Roll Forming Machine,100% made in China,is to fully produce automatically the production of C Stud and U Tack with options for punching holes and embossing customer logos their main advantages are stable operation with a strong body frame and customized designs.

Metal framing include furring channel,carrying channel,studs,tracks,wall angle,and main frame channel used in concealed grid gypsum ceiling of light weight structure.Two most commonly used frames are metal U Track,used as the horizontal framework of stud partitions,in conjunction with vertical studs(C Studs).

Strong,lightweight,simple to install,and available in a variety of sizes,metal studs and channels provide for the ideal and cost-effective wall and ceiling applications when used with several layers of gypsum board.

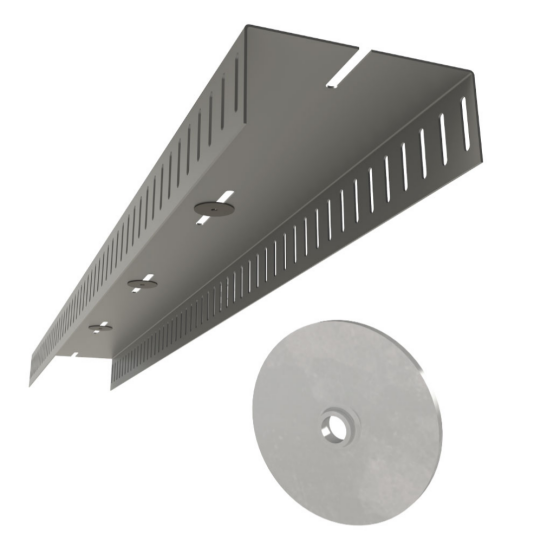

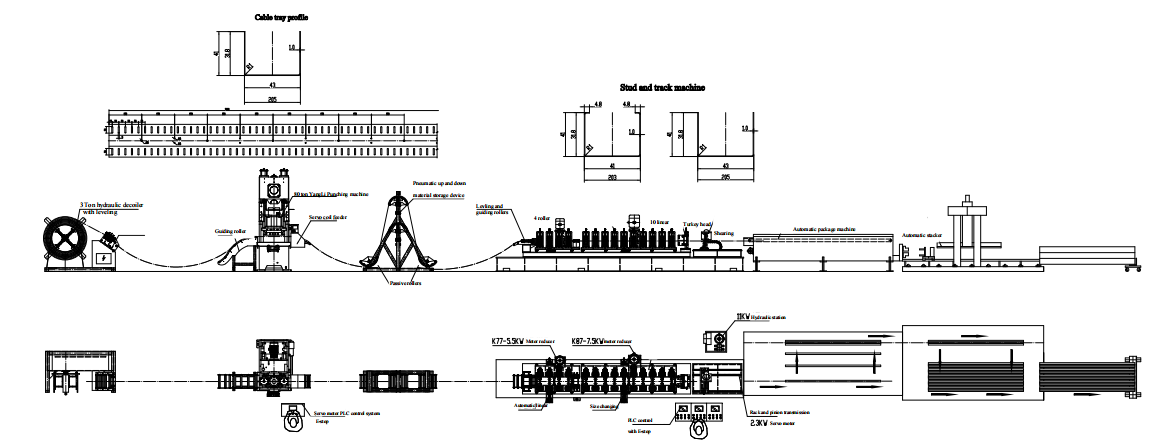

Here is one drawing profile and finished product:

What is the seismic drift track?

ZTREM Seismic Drift Track (D) allows for lateral movement of the main building structure, while still accomodating head-of-wall deflection and fire ratings for interior and exterior walls. The Seismic Drift Track comes with an extruded metal insert that aids in the connection of the track to the main structure.

The differences of product:

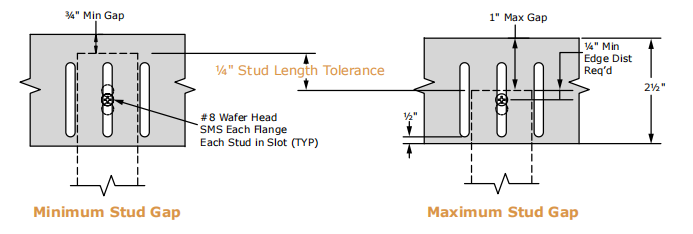

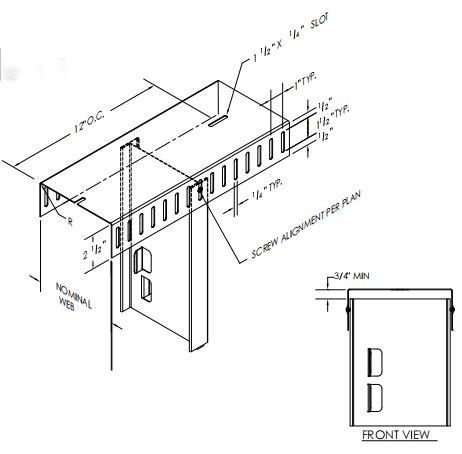

SLT - Standard Slotted Leg Track

The SLT Slotted Deflection Track allows for a positive attachment of the stud to the

top track through the slots designed to accommodate the vertical movement of the

primary structure, in compliance with Section 713.2 of the IBC.

The SLT is designed to allow a total vertical movement of 1 ½" (+/- ¾").

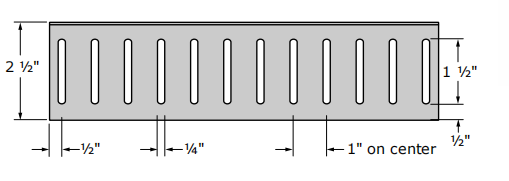

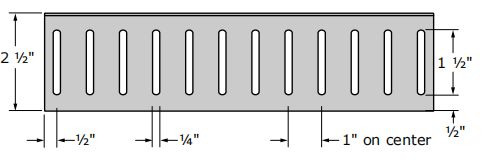

Dimension

The section legs (flanges) are 2 ½" in length and have 1 ½"

long by ¼" wide vertical slots spaced every 1" along the length

of the member.

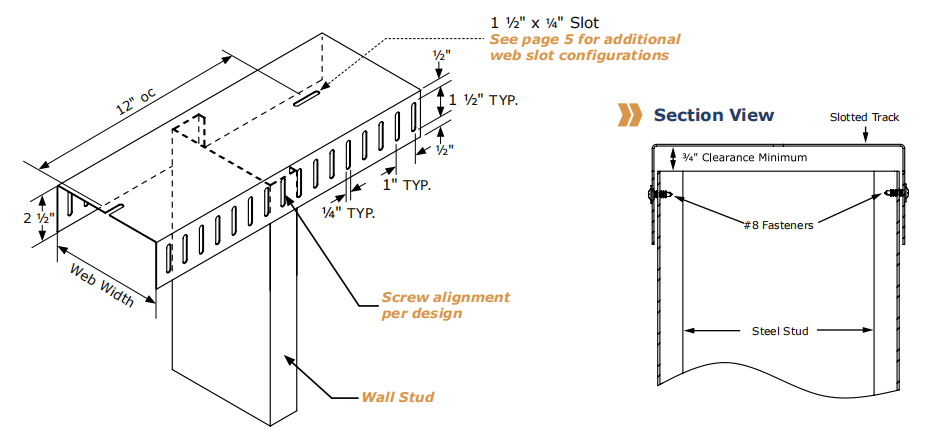

Standard Slotted Leg Track Detail (SLT)

Specifications

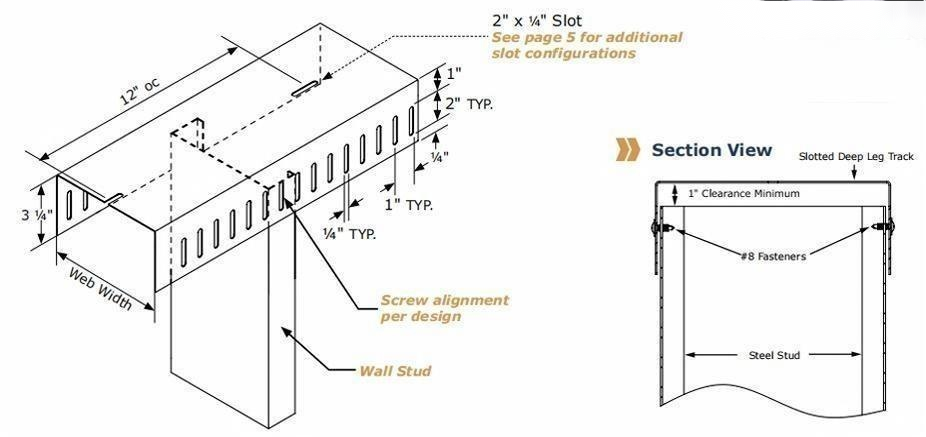

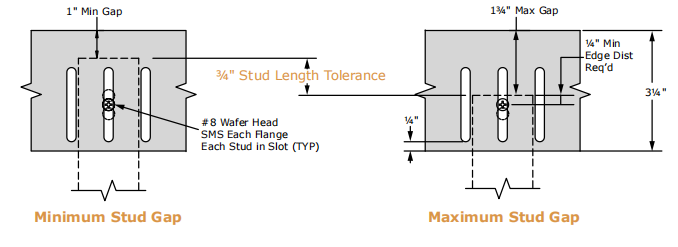

SDLT - SLOTTED Deep Leg Track

The SDLT Slotted Deep Leg Track allows for a positive attachment of the stud to the

top track through the slots designed to accommodate the vertical movement of the

primary structure, in compliance with Section 713.2 of the IBC.

The SDLT is designed to allow a total vertical movement of 2" (+/- 1").

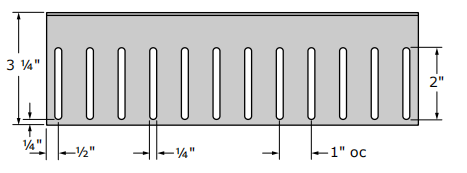

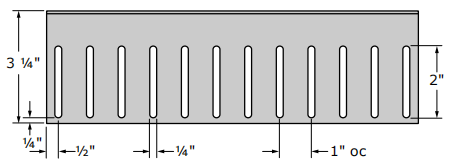

Dimension

The section legs (flanges) are 3 ¼" in length and have 2" long by

¼" wide vertical slots spaced every 1" along the length of the member.

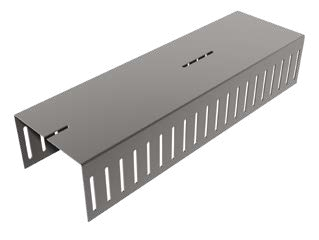

Slotted Deep Leg Track Detail (SDLT)

Specifications

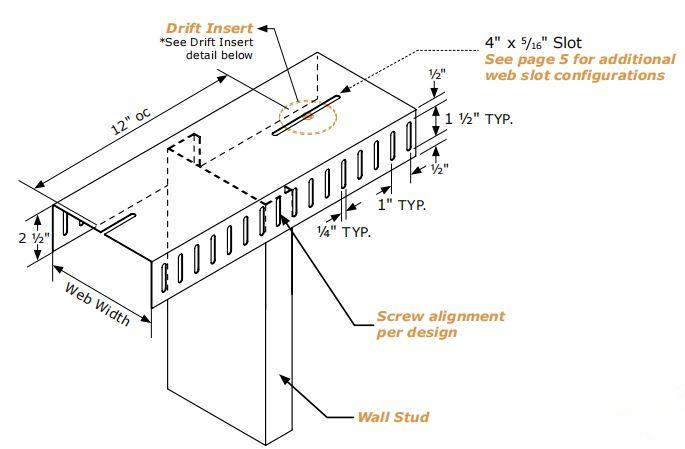

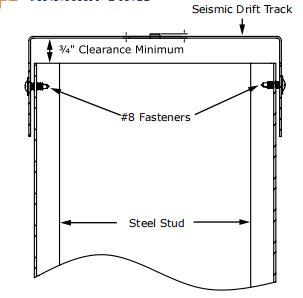

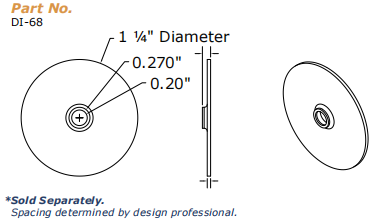

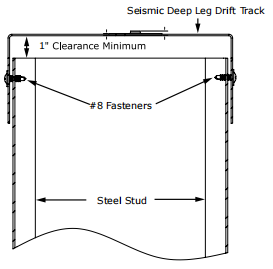

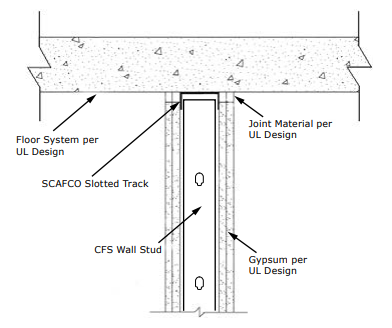

D - Seismic Drift Track

Seismic Drift Track (D) allows for lateral movement of the main building

structure, while still accomodating head-of-wall deflection and fire ratings for interior

and exterior walls. The Seismic Drift Track comes with an extruded metal insert that

aids in the connection of the track to the main structure.

Dimension

The section legs (flanges) are 2 ½" in length and have 1 ½" long by ¼"

wide vertical slots spaced every 1" along the length of the member.

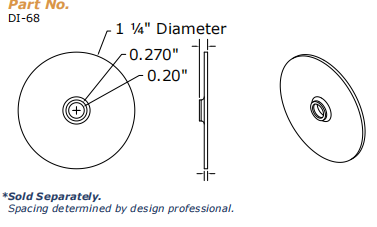

Seismic Drift Track (D)

Drift Insert Detail Section View

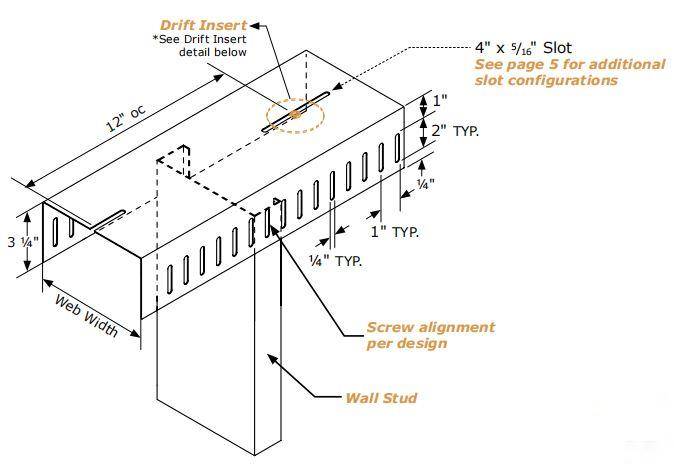

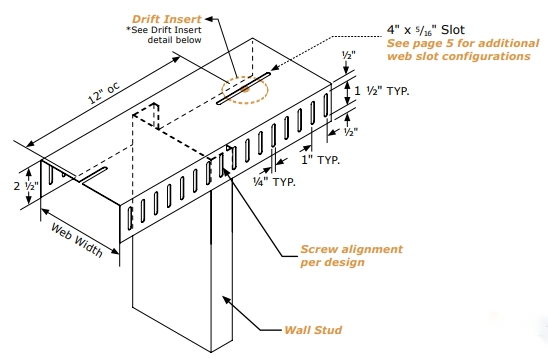

DD - Deep Leg Seismic Drift Track

Deep Leg Seismic Drift Track (DD) allows for lateral movement of the main

building structure, while still accomodating head-of-wall deflection and fire ratings

for interior and exterior walls. The Deep Leg Seismic Drift Track comes with an

extruded metal insert that aids in the connection of the track to the main structure.

Dimension

The section legs (flanges) are 3 ¼" in length and have 2" long by ¼" wide

vertical slots spaced every 1" along the length of the member.

Deep Leg Seismic Drift Track (DD)

Drift Insert Detail Section View

I-Stud Shaftwall System

UL Head-of-Wall Joint Systems Design Numbers

Seismic drift track features and applications:

1.Fire-rated deflection system

2.UL Classified in over 80 approved fire-rated systems

3.Standard Slotted Track allows up to 1½” of vertical movement

4.Custom shapes and slot sizes available

5.Custom widths and thicknesses available

6.Positive attachment provided for wall strength

7.Absorbs head-of-wall and floor extension or compression movement

8.Integrated with traditional wall systems

9.Easy installation reduces labor costs

Material / Product Specification:

Nonstructural (Drywall) Products:

Ø 18-30 mil: 33 ksi

Ø 25EQ: 50 ksi

Ø 20EQ, 30EQD: 57 ksi…………ASTM A1003/A653, C645

Structural Framing Products:

Ø 33-43 mil: 33ksi

Ø 33EQS, 43EQS: 57 ksi

Ø 54-127 mil: 50 ksi…………ASTM A1003/A653, C955

Coating Specification

Nonstructural (Drywall) Products:

Ø 25EQ, 20EQ, 30EQD, 18-30 mil: G40…………ASTM A1003/A653, C645

Structural Framing Products:

Ø 33EQS, 43EQS, 33-97 mil: G60…………ASTM A1003/A653, C955

Note: Contact ZTREM for heavier coating thickness availability.

High speed automatic seismic drift track machine rolling forming machine

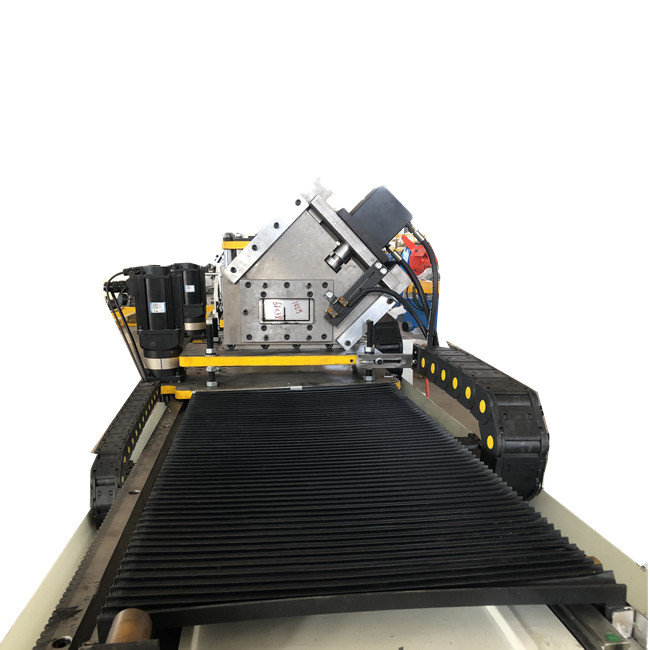

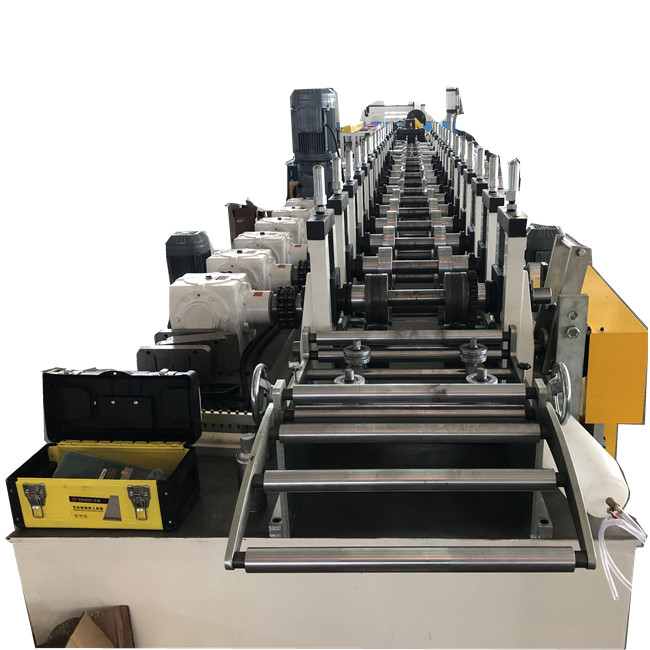

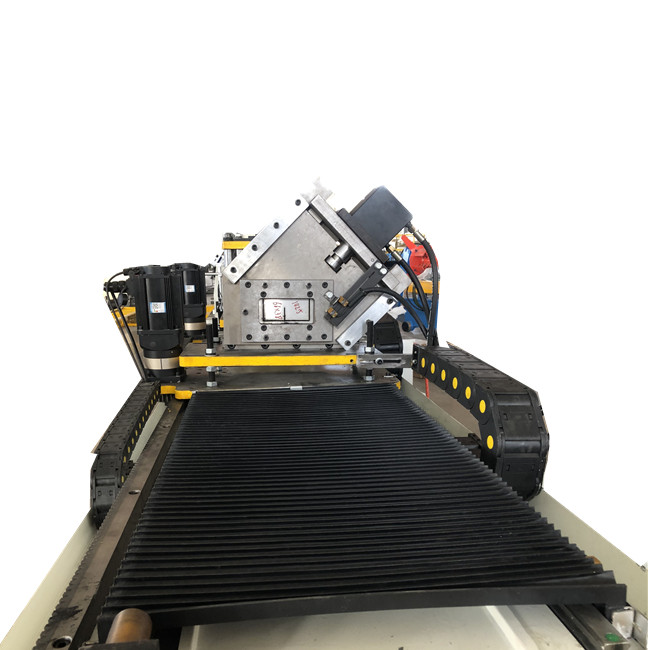

Working flow: 3 ton double head decoiler --cage loop-->80 ton YangLi punching machine- cage loop --main rolling forming machine-stud and track punching--> convey table and stacker.

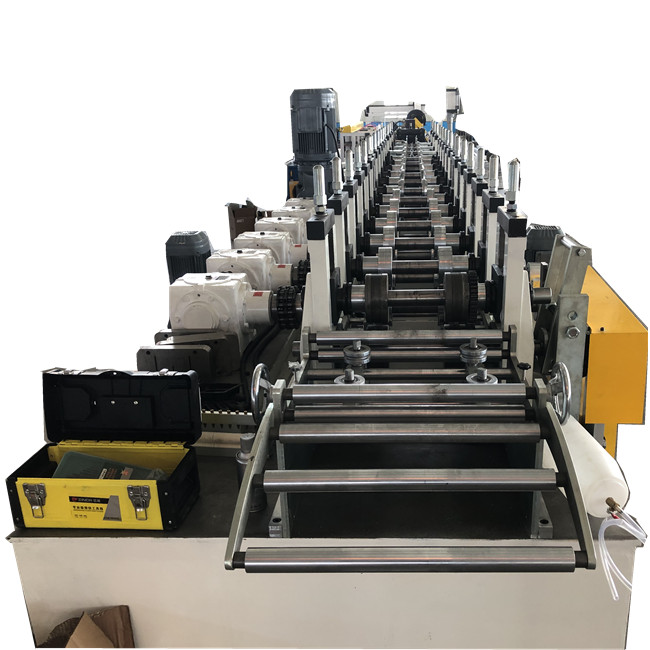

Performance characteristics:

1. The steel plate welding fuselage is rigid and the precision is stable.

2. Dry or wet type pneumatic friction clutch brake, the action is sensitive and reliable.

3.Big gear, gear shaft precision grinding, machine tool running noise is low.

4.Sliding block six-sided guide rail, with pneumatic balance device, smooth operation, accurate accuracy.

5. Adopt hydraulic overload protection device to protect press and mould effectively.

6.The single or multi-machine automatic stamping production line can be formed by using PLC to control the automatic feeding device.

7.In addition to the constant speed, there are two kinds of stepless speed stroke selection, which is more suitable for stamping parts process requirements and improve production efficiency.