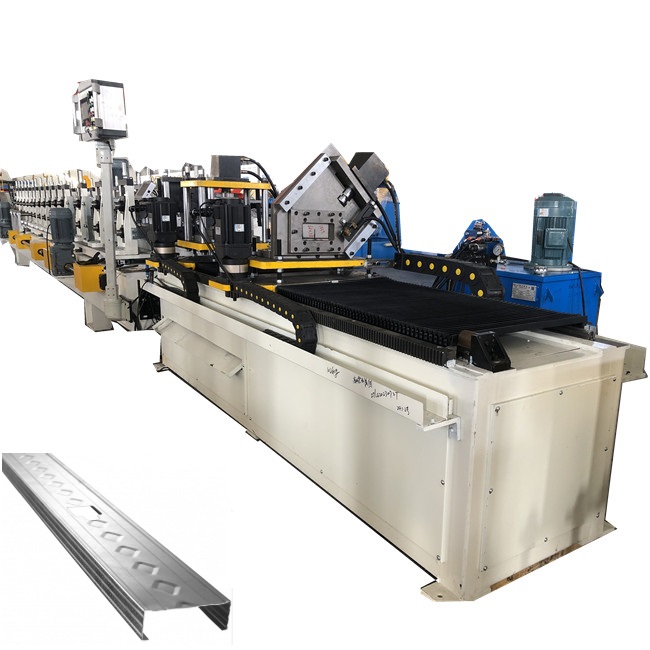

High Speed Automatic Drywall Track Rolling Forming Machine

High Speed Automatic Drywall Track Rolling Forming Machine, also known as drywall framing machines or metal stud roll forming machines, are specialized industrial machines used in the construction industry for manufacturing metal studs and tracks for drywall partition systems. These machines automate the process of producing metal framing components, providing efficiency and precision in the construction of interior walls.

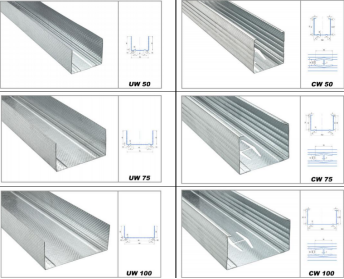

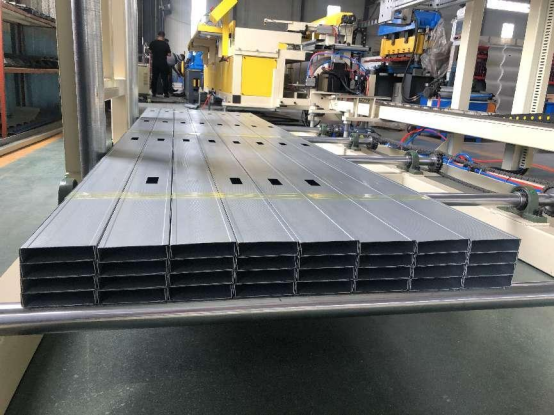

Here is one drawing profile and finished product:

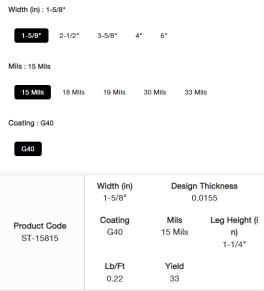

Select your product below:

Product details:

A proven interior steel stud solution; ZTRFM Interior Drywall products are manufactured under ISO 9001 and ISO 14001 certified Quality and Environmental management systems. Featuring a wide range of components, ZTRFM Interior Drywall Studs are rolled from China made steel. The ZTRFM Interior Drywall systems are available in:

1/5/8″, 2-1/2″, 3-5/8″, 4″ and 6″ wide steel stud sizes

Design thicknesses from 0.0155 – 0.0346

15, 18, 19, 30, 33 Mils Solutions

High Speed Automatic Drywall Track Rolling Forming Machine

How do High Speed Automatic Drywall Track Rolling Forming Machine work?

1. Material Feeding: The machine is equipped with a material feeding system that supplies a continuous strip of galvanized steel coil or other suitable metal material. The material is typically per-punched with holes to facilitate screw attachment during installation.

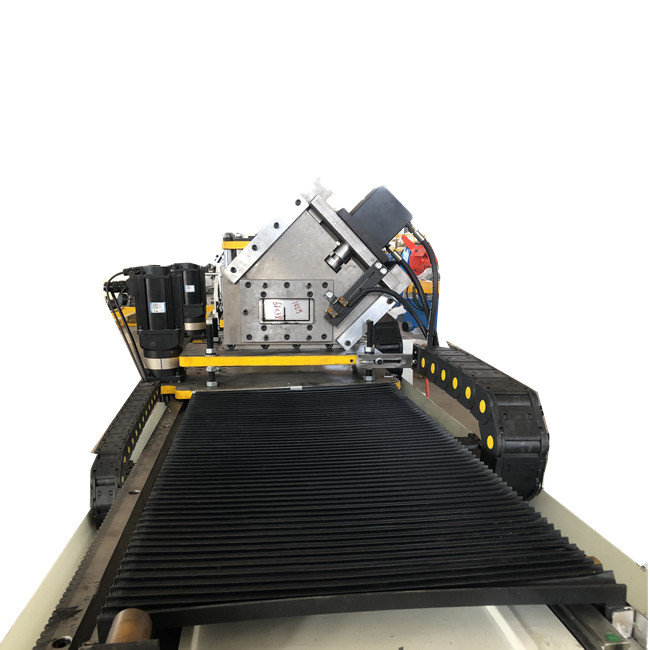

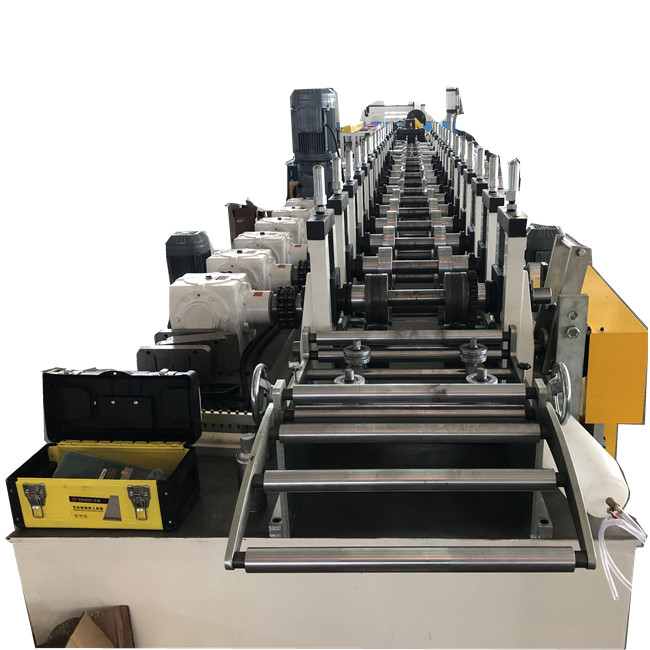

2. Roll Forming: The metal strip passes through a series of rollers that gradually shape the material into the desired profile. For stud and track production, the rollers are designed to create the specific dimensions and features required for metal studs and tracks. This includes forming flanges, lips, and embossments for strength and rigidity.

3.Cutting and Punching: Once the desired length of the stud or track is achieved, the machine includes cutting and punching mechanisms. The cutting mechanism can be a flying cutoff, shear, or other cutting method, which cuts the formed metal component to the desired length. Simultaneously, the punching mechanism creates holes for electrical wiring, plumbing, and other utilities to pass through the studs and tracks.

4.Stacking and Packaging: After the metal components are formed, cut, and punched, they can be automatically stacked and packaged for easy transportation and installation. The machine may incorporate an automated stacking and bundling system to efficiently handle the finished components.

What are the benefits of High Speed Automatic Drywall Track Rolling Forming Machine?

High Speed Automatic Drywall Track Rolling Forming Machine offer several benefits, including:

1.Efficiency: These machines automate the manufacturing process, reducing manual labor and increasing production speed. They can produce consistent, high-quality metal studs and tracks at a rapid rate.

2.Accuracy and Precision: High Speed Automatic Drywall Track Rolling Forming Machine ensure precise shaping, cutting, and punching of the metal components, resulting in accurate dimensions and hole alignments. This facilitates easier and faster installation on the construction site.

Flexibility: The machines can be set up to produce different sizes and profiles of metal studs and tracks by adjusting the rollers and tooling. This allows for customization based on specific project requirements.

3.Cost-effectiveness: By producing metal studs and tracks in-house with a dedicated machine, contractors can save on purchasing per-fabricated components, reduce material waste, and have better control over the supply chain.

4.Stud and track machines are essential equipment in the drywall construction industry, providing a streamlined and efficient solution for manufacturing metal framing components.