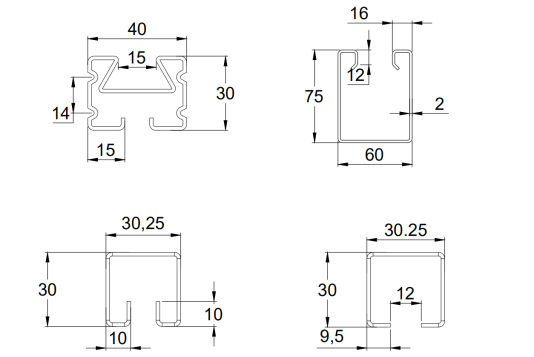

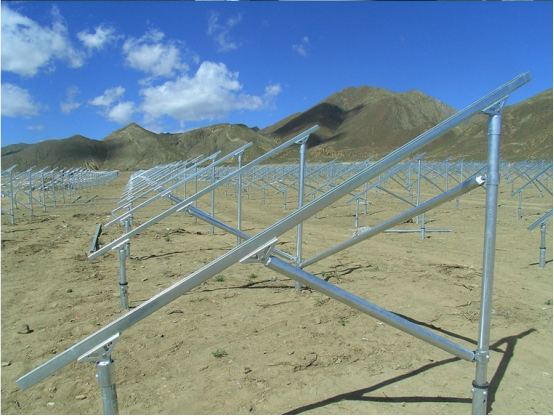

Description:The Strut Channel Roll Forming Machine serves two primary applications: one is known as the seismic support roll forming machine or seismic channel roll forming machine, dedicated to producing components used for mounting, bracing, supporting, and connecting lightweight structural loads in building construction. The other application is referred to as the solar rack roll forming machine or photovoltaic (PV) rack roll forming machine, specifically designed to manufacture PV support brackets for solar panel installations.

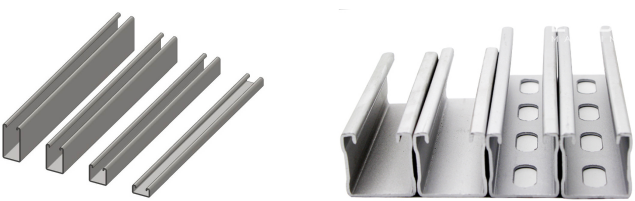

Strut channels are primarily made from galvanized steel, which offers excellent corrosion resistance and durability. However, they can also be made from aluminum or stainless steel for applications requiring additional resistance to corrosion or specific aesthetic considerations. And they come in different sizes and configurations to suit specific applications.

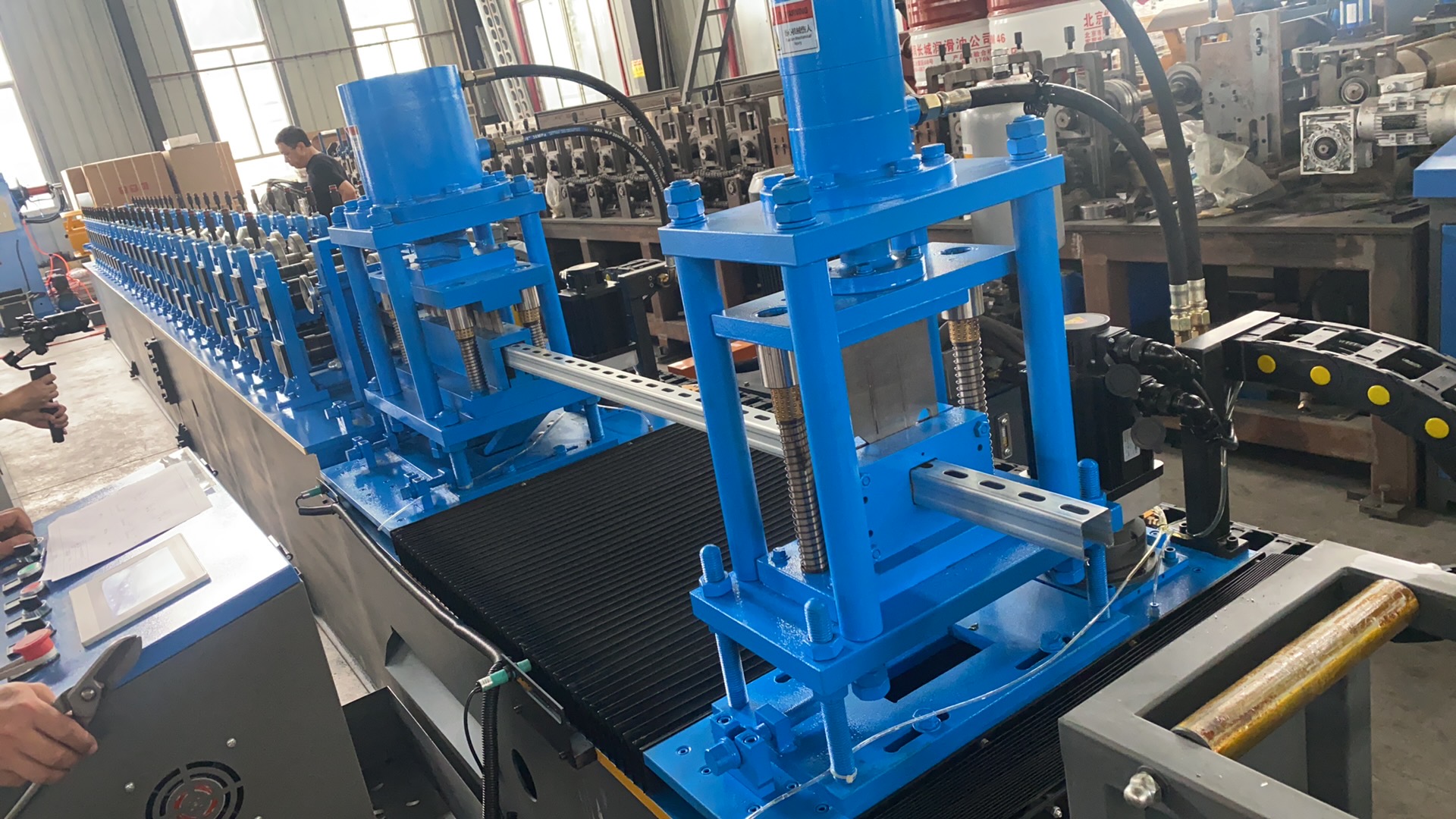

Fast Speed 20m/min-Strut Channel Roll Forming Machine

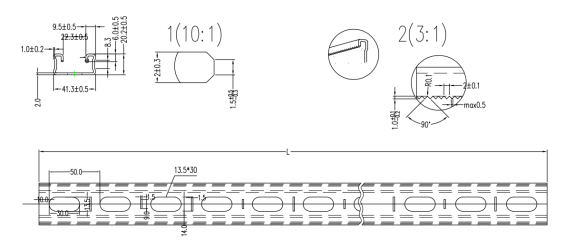

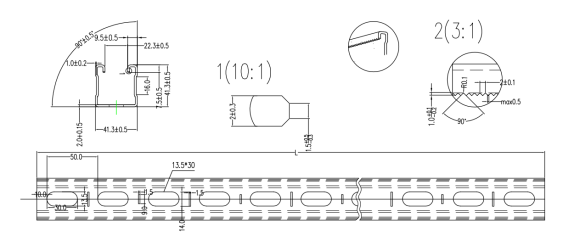

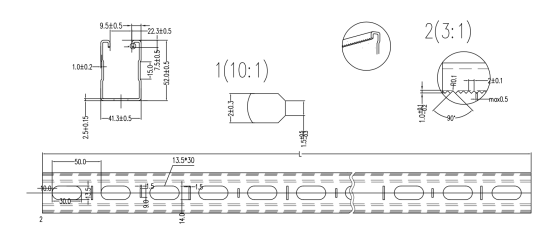

Strut channels are commonly categorized by their width and height dimensions. The most common widths are 41mm and 21mm, while the height can range from 21mm to 41mm or more, depending on the specific requirements of the project.

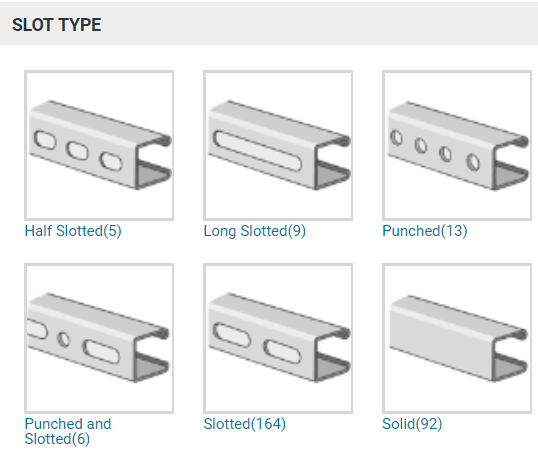

According to slot type, we have many different types of strut channels. These holes allow for easy attachment of fittings, brackets, and other accessories, making them versatile for various installation needs:

Solid channel has no holes predrilled, and must either be drilled on site or mounted in another fashion.

Punched channel has round holes, large enough for 5/8 inch threaded steel rod or bolts, punched in the top of the channel at regular 1 7/8 inch centers.

Half-slot channel has short, rounded end rectangular slots punched out on 2 inch centers. Slot channel has longer slots on 4 inch centers.

In addition, shapes are manufactured with two lengths of channel welded together back to back, side to side or three or four welded together in various patterns, to form stronger structural elements.

Application:

Solid Type Reforced and teeth type

Machine Production Process

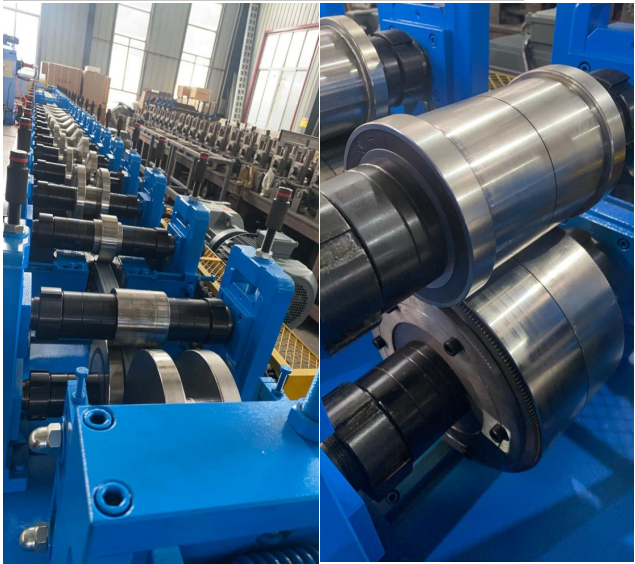

This production line consists of several essential components, including the decoiler, leveling machine, punching system, storage track, roll former, and cutting system. The roll former is designed with a robust cast-iron frame and high power motor to ensure stability and strength in the production process. Meanwhile, the cutting system adopts hydraulic cutting, eliminating the need for saw blade replacements, reducing costs, and minimizing noise issues. The combination of these features makes this production line highly efficient and cost-effective for various manufacturing needs.

Fast Speed 20m/min-Strut Channel Roll Forming Machine

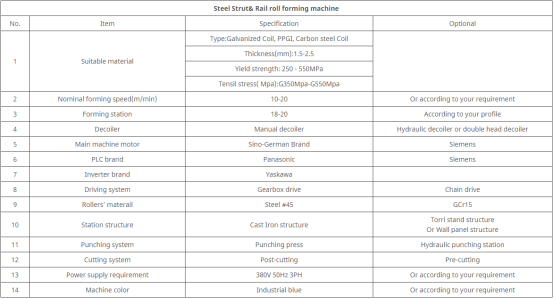

Technical Specification

Solar panel frame roll forming machine product application

Detailed Images of Fast Speed 20m/min-Strut Channel Roll Forming Machine

Fast Speed 20m/min-Strut Channel Roll Forming Machine straightened device

Fast Speed 20m/min-Strut Channel Roll Forming Machine puncher and the step into device

Fast Speed 20m/min-Strut Channel Roll Forming Machine arc feeding device

Fast Speed 20m/min-Strut Channel Roll Forming Machine rollers

Fast Speed 20m/min-Strut Channel Roll Forming Machine hydraulic post cutter

Profile drawings