Description:The strut Channel roll forming machine is a powerful and versatile piece of equipment capable of meeting the production needs of strut channels in solar photovoltaic mounting systems. It boasts features like high precision, long service life, ease of operation, and provides various optional features and customization options.

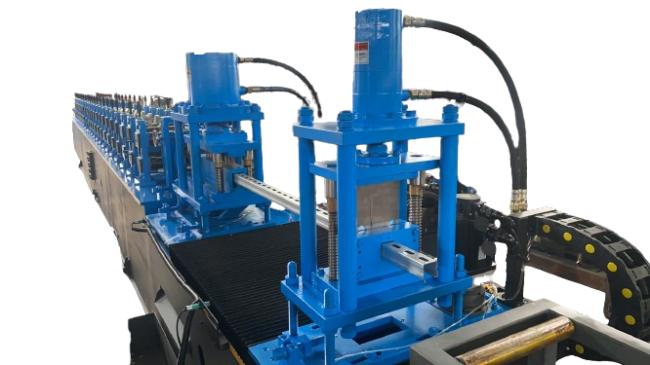

C Strut Channel Forming Machine

ZTRFM manufacture most popular type and size of slotted strut channel roll forming

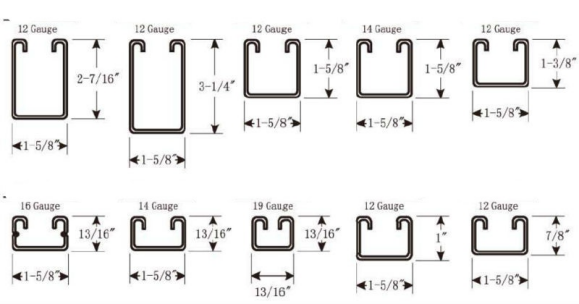

41mmx41mm

41mmx 21mm

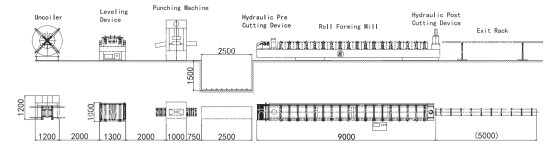

Strut channel forming machine process:

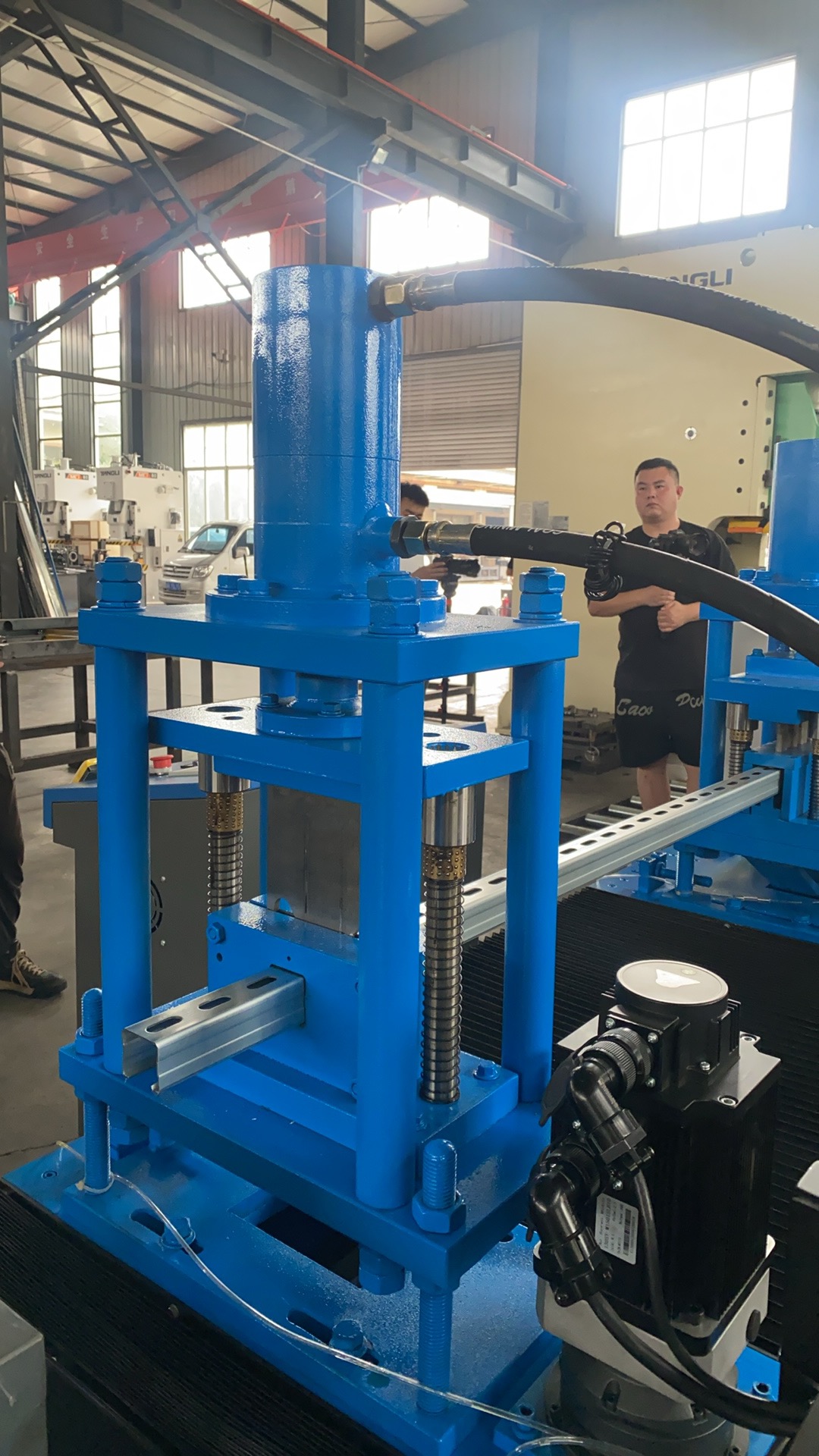

Decoiler the coil- leveling- servo feeding- punch -forming – cut- run out table

Main features of c struct channel forming machine:

Suitable for material1.2-2.5mm

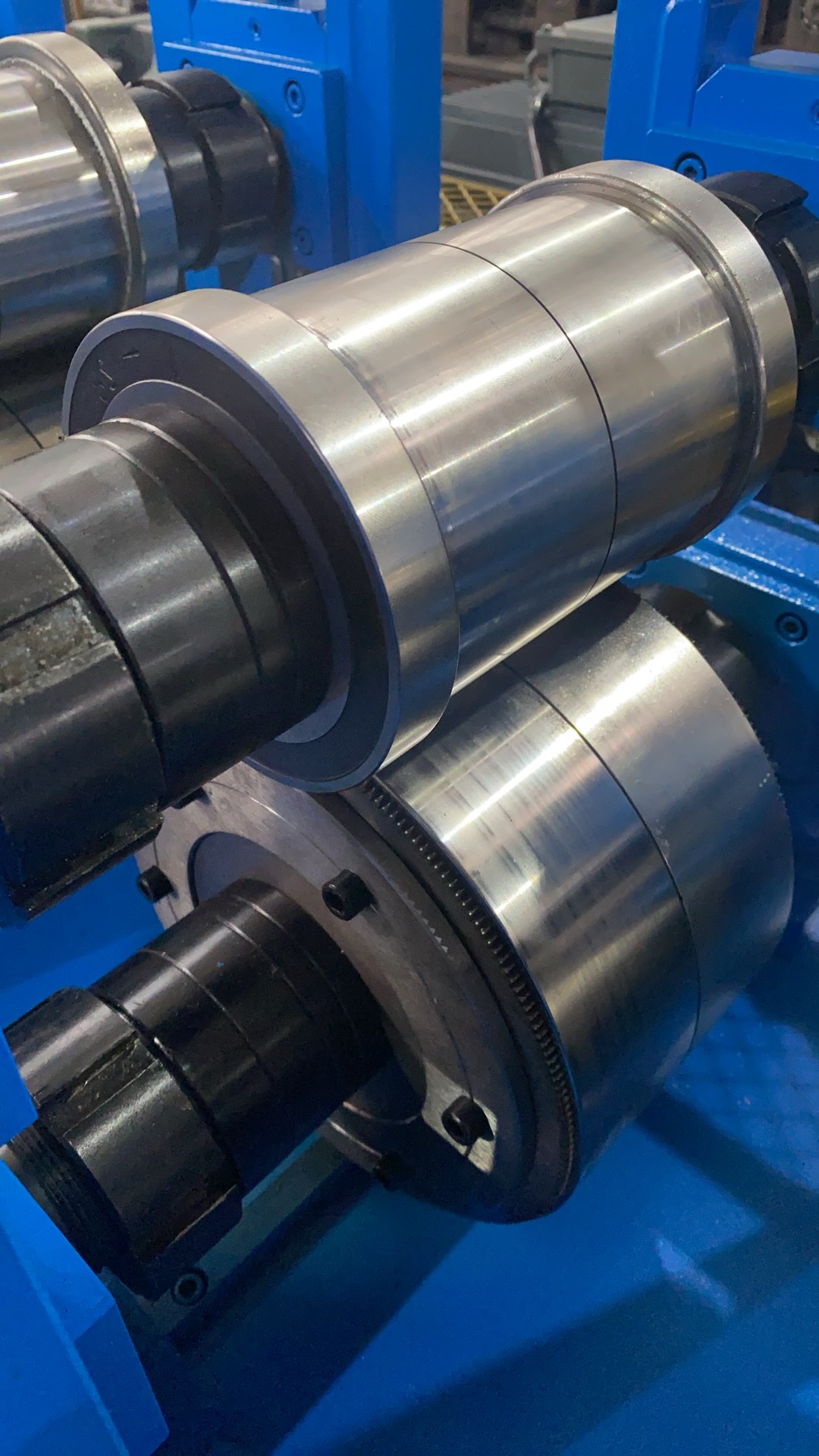

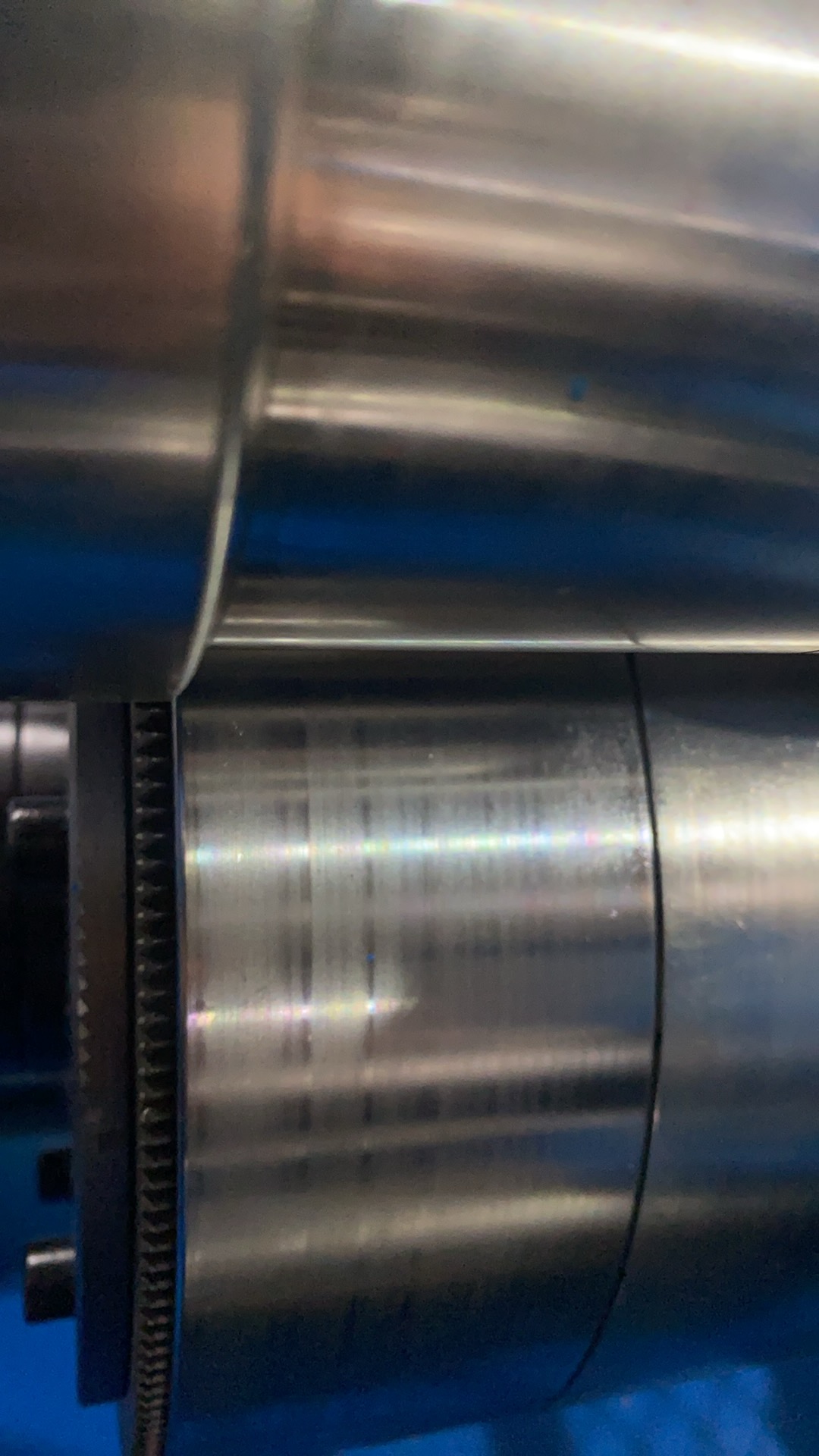

Roller material Gcr15 mould steel

Gear and chain move the line or gearbox move the line are optional

This strut channel with perfect curved edges, used to support solar panel to collect sun energe for electricity.

Strut channels provide ideal framework for support system without the need for welding, full flexibility and easy install.

Strut Channel Types

Work Flow

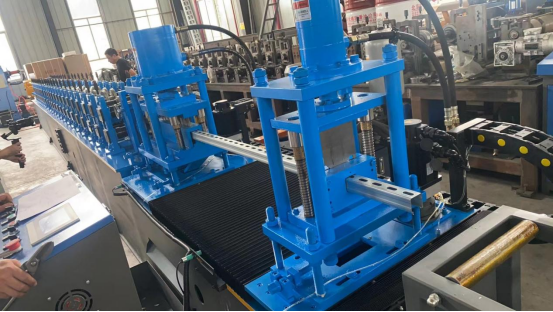

C Strut Channel Forming Machine

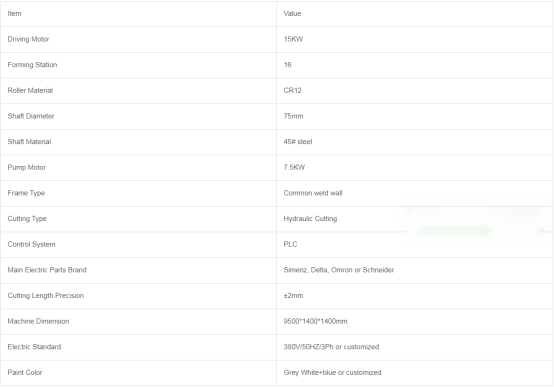

Machine Parameters

Purpose of the Equipment:

Primarily used for producing strut channels in solar photovoltaic mounting systems. These channels are utilized for installing, supporting, and connecting lightweight structural loads in construction projects.

Production Capacity:

The production capacity of the equipment varies depending on the manufacturer. Our roll forming machines can achieve a rolling speed of up to 30m/min, typically ranging between 25-30m/min.

Material Compatibility:

The machine can process various types of raw materials, including hot-rolled and cold-rolled steel, hot-dip galvanized sheets, pre-galvanized steel, mill (plain/black) steel, aluminum, stainless steel, and more.

Product Specifications:

Based on the design and configuration of the equipment, it can produce different specifications and types of strut channels, such as solid channels, slotted channels, half-slotted channels, long-slotted channels, perforated channels, and a combination of perforated and slotted channels.

Machine Features:

The equipment typically boasts high precision and long service life, ensuring the high quality and stability of the produced strut channels.

It is easy to operate, reducing the skill requirements for operators.

Technical Specifications:

The specific technical specifications of the equipment may include the roll forming machine’s dimensions, weight, power, voltage, etc. For instance, some models may weigh up to 5000kg, while others may be lighter.

Additional Attributes:

The equipment may offer various optional features, such as customized logos, customized packaging, customized patterns, and more.

The machine is equipped with core components like PLC control systems, engines, bearings, gearboxes, motors, pressure vessels, gears, pumps, and so on.