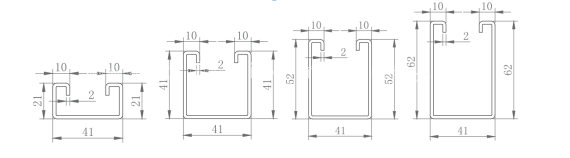

Description:Strut Channel is a standard cold roll formed steel used in electrical industry or constructions for structural support. Which is usually formed from metal coil strips, roll formed into an open channel section with lips to provide additional stiffness. The basis strut channel sizes are: 41*41. 21*21, and also some customized shapes.

Strut Channel Roll Forming Machine 4 In 1 For USA

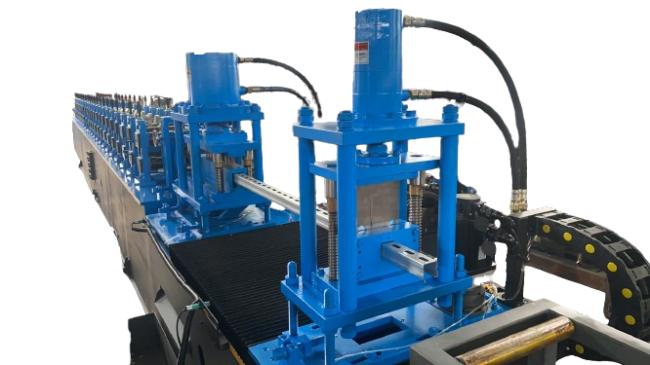

The strut Channel roll forming machine is a powerful and versatile piece of equipment capable of meeting the production needs of strut channels in solar photovoltaic mounting systems. It boasts features like high precision, long service life, ease of operation, and provides various optional features and customization options.

Profile Drawing

Sample Show

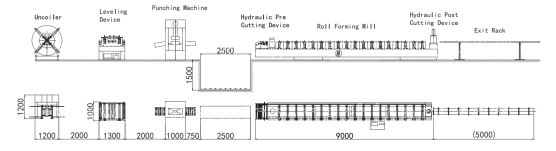

Work Flow

Strut Channel Roll Forming Machine 4 In 1 For USA

Equipment Advantages

1.The Production Line Uses High-Speed Punching Machine And Skd11 Material Mold,So As To Ensure That 12 Meters Of Board Can Be Punched In One Minute.

2.The Production Line Can Produce Four Different Height Profiles,So As To Achieve Multi-Specification Production And Less Floor Space.

3.In Order To Reduce The Deformation Of The Incision,The Post-Cutting Device Of This Equipment Adopts The Method Of Shearing From Bottom To Top.

Material of Strut Channel Roll Forming Machine 4 In 1 For USA(Luxury Type)

1.Material Thickness: 2.0-2.5mm

2.Applicable material:GI/GL/PosMAC

3.Material Yield Strength :235-390Mpa

4.Feeding width:About 98-179mm

Introduction to machine decomposition

1.5T-600 Hydraulic Uncoiler

Hydraulic control of the inner holes of the steel roll contraction and stopping

MAX. Feeding width: 600 mm

Inner diameter of the coil: 508 ± 30mm, outer diameter: 1500mm

Maximum capacity: 5 tons, motor: 3KW, frequency conversion speed adjustment

Oil pump motor: 3KW

Increase automatic feeding power and automatic shutdown device

Liquid pressure arm device

2.Leveling Device

Upper three, down four, and seven rollers leveling device.

With the feeding guide rail, the main framework is welded with H450 steel.

The axis is made of 45#steel, which is hot and hot, and hard chrome.

Diameter = φ90 mm, precision processing.

Electric power: 3 kW.

3.Servo Feeding Device

4.63T Yangli Cylinder Punching Machine

The 63-ton high-speed punch is equipped with a set of punching models before roll forming.

The punch has safety covers on all sides and doors on one side.

Controlled by the PLC system.

The feeding motor is more accurate by the servo motor, the servo motor power is 3KW.

5.Punching Mould

6.Hydraulic Pre Cutting Device

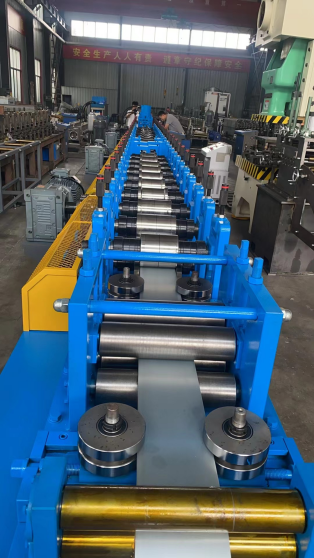

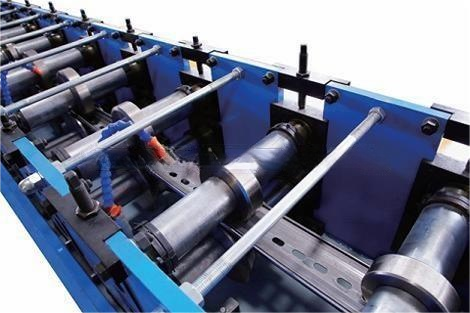

7.Roll Forming Mill

With the feeding guide rail, the main framework is welded with H400 steel.

Side wall thickness: Q235 T18mm;

Tie rod: ф22 galvanized

The rolling wheels use bearing steel GCR15 (= EN31 steel) precision processing, the surface is hard chrome, 0.04mm thick, and the surface mirror treatment (longer service life, stronger rust);

The shaft is made of 45# steel, quenched and tempered heat treated, hard chrome plated.

Diameter = 80 mm, precision processing.

Gear and chain movement about 22 steps to form.

Main motor (Poli Lai brand) = 15kW, frequency speed adjustment.

8.Cooling system

9.Hydraulic Post Cutting Device

Post to cut, stop to cut, two -piece cutting design without feeding

Hydraulic motor: 5.5kW

Cutting tool material: CR12Mov (= SKD11, has at least one million cutting life), heat treatment to HRC58-62 degrees

The cutting power is provided by the host's independent hydraulic station

10.Hydraulic Station

11.PLC Control System

Automatic control quantity and cutting length

Enter production data (production batch, number of production pieces, production length, etc.) on the touch screen,

Automatically complete production.

Combine: PLC, inverter, touch screen, encoder, etc.

12.Exit Rack

No motivation, two units, rolling wheels on it, easy to move