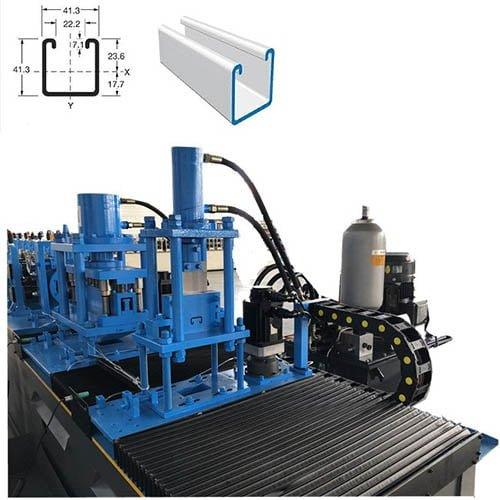

Description:Unistrut C Channel Roll Forming Machine is design for produce 41*41 41*21 high quality perforated Unistrut C Channel, which used in solar panel post pv system.

Slotted Unistrut Channel Roll Forming Machine

Slotted Unistrut Channel Roll Forming Machine is a specialized equipment for producing solar photovoltaic stents. It processes metal materials into the desired bracket profiles through cold bending and molding techniques.

These molding machines usually have a highly automated production process, which can improve production efficiency and product quality.

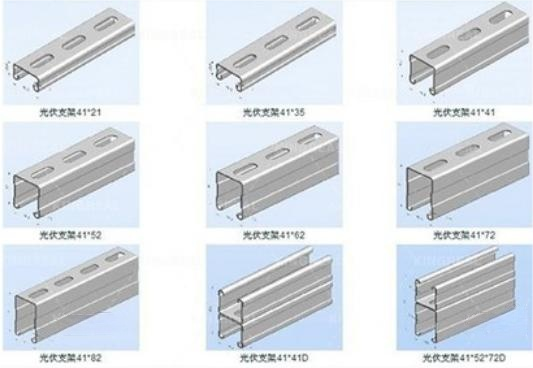

Unistrut C Channel Basic Type

Common Size Types Include: 41mm*41mm/ 41mm*21mm

Common Shape:

U-shape: U-shape bracket is named because of its upward "U" shape, which has good rigidity and stability, can withstand large loads, and is often used in areas with highwind1.

Hat-shape: hat-shape brackets usually refer to brackets with a curved top, which helps to reduce wind resistance and improve the stability of the structure.

C-type: C-type brackets have a "C" shaped cross-section and are characterized by light weight, good rigidity and durability, and are suitable for large-scale PV power plants or high-standard PV power generation projects.

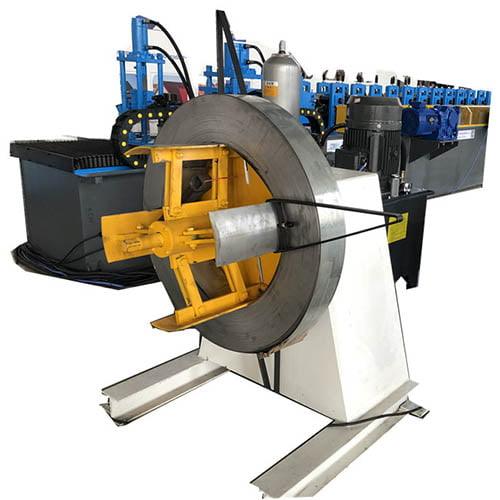

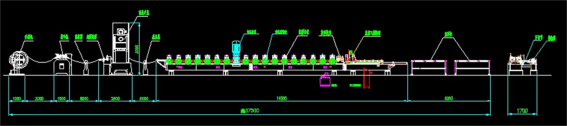

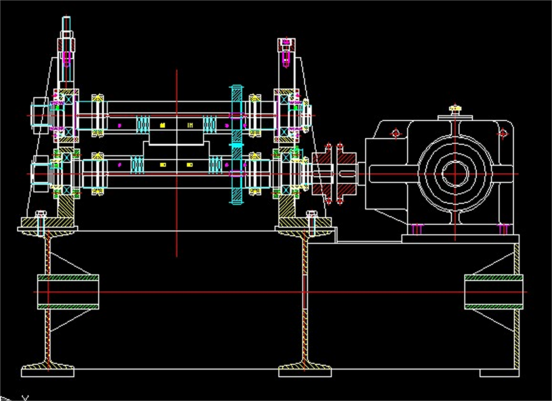

Working Process Of Unistrut C Channel Machine

Slotted Unistrut Channel Roll Forming Machine

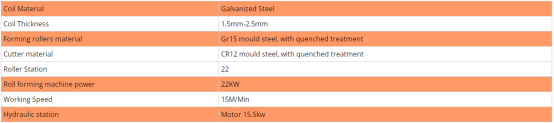

Technical Specification

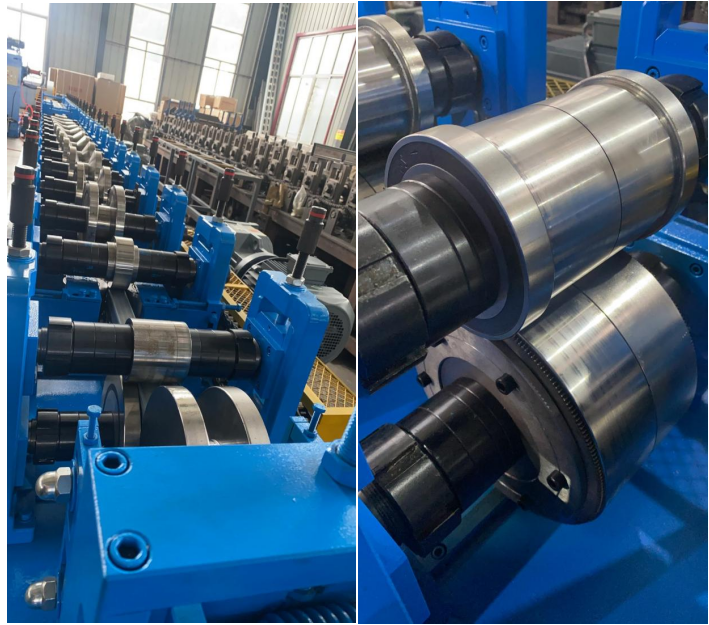

Features Of Unistrut Slotted Channel Machine

Efficient Production

adopting advanced automated production technology to realize fast and efficient processing and assembly, improving production efficiency and product quality.

Energy saving and environmental protection: focusing on energy saving and environmental protection in design, it adopts advanced hydraulic system, energy-saving motor and high-efficiency transmission device, which reduces energy consumption and heat loss, and lowers production cost.

Intelligent operation: equipped with an intelligent control system, the photovoltaic bracket molding machine can realize automated production process and reduce manualintervention.

Versatile Processing

able to process various materials such as steel plate, aluminum plate, etc., and manufacture various specifications of brackets to meet different market demands.

Stability: fast running speed and simple operation ensure the stability of product quality, which is welcomed by more and more manufacturers.