Description:Unistrut channels, also known as strut channels or metal framing channels, are widely used for structural support in various applications. The roll forming process plays a crucial role in producing high-quality Unistrut channels with precision and efficiency. We will discuss the importance of Unistrut channels, the roll forming process, and the advantages of utilizing Unistrut channel roll forming machines in manufacturing operations.

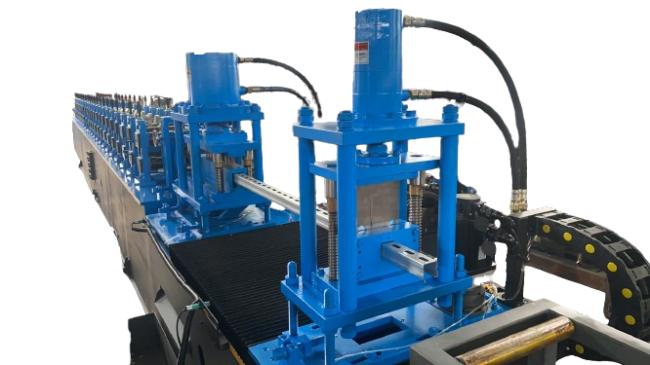

High Quality Unistrut channel roll forming machines

The roll forming process is a highly efficient and precise method for manufacturing Unistrut channels. It involves feeding a continuous strip of metal through a series of rollers that gradually shape the material into the desired profile. Here are the key steps involved in the roll forming process:a. Material Feeding: The roll forming machine receives a continuous coil of metal, typically steel or aluminum, which is fed into the machine’s entry section.b. Pre-Punching (Optional): Depending on the specific requirements, the roll forming machine may incorporate pre-punching stations to create holes or slots in the material.c. Roll Forming: The metal strip passes through a series of rollers, each designed to gradually bend and shape the material to match the Unistrut channel profile. The rollers are precisely positioned and controlled to ensure accuracy and consistency.d. Cutting and Shearing: Once the desired length of the Unistrut channel is achieved, the roll forming machine performs the cutting or shearing process to separate the formed channel from the remaining strip.e. Finalizing and Stacking: After cutting, the Unistrut channels undergo any necessary final shaping, such as curving or flanging. They are then stacked or conveyed for further processing or packaging.

Here Is The One Drawing Profile For Your Reference:

High Quality Unistrut channel roll forming machines

The Significance of Unistrut Channels

Unistrut channels serve as a versatile framing system in the construction, electrical, and mechanical industries. They provide a robust framework for supporting electrical conduits, cable trays, HVAC systems, plumbing, and other infrastructure components. The key advantages of Unistrut channels include:a. Strength and Load-Bearing Capacity: Unistrut channels offer excellent load-bearing capabilities, making them suitable for supporting heavy equipment, piping, and structural components.b. Flexibility and Adjustability: The modular design of Unistrut channels allows for easy configuration and adaptability to changing project requirements.c. Cable Management: Unistrut channels provide a practical solution for organizing and routing electrical cables, reducing the risk of damage and enhancing safety.d. Time and Cost Efficiency: Unistrut channels simplify installation processes, saving time and reducing labor costs during construction or retrofitting projects.

Advantages of Unistrut Channel Roll Forming Machines

Utilizing Unistrut channel roll forming machines offers several advantages for manufacturers:a. Increased Production Efficiency: Roll forming machines enable high-speed production, significantly reducing production time compared to traditional fabrication methods. They can produce Unistrut channels at a consistent rate, leading to enhanced productivity and output.b. Precision and Consistency: Roll forming machines ensure precise and consistent shaping of Unistrut channels throughout the production process. The machines’ advanced controls and automated systems result in accurate dimensions, hole patterns, and profile shapes.c. Customization and Design Flexibility: Unistrut channel roll forming machines offer the ability to customize various parameters, such as channel width, height, thickness, hole spacing, and flange dimensions. This flexibility allows manufacturers to meet specific customer requirements and produce tailored Unistrut channels.d. Cost Optimization: By utilizing roll forming machines, manufacturers can optimize production costs. The high-speed production capabilities, material savings, and reduced labor requirements contribute to improved cost efficiency and profitability.e. Quality Control: Roll forming machines provide consistent quality control, ensuring that each Unistrut channel meets the required specifications. Through precise control over the roll forming process, manufacturers can minimize variations, defects, and material waste.f. Versatility and Adaptability: Unistrut channel roll forming machines are versatile and can be adapted to produce different profile shapes or sizes beyond Unistrut channels. This versatility allows manufacturers to expand their product offerings and cater to diverse market demands.