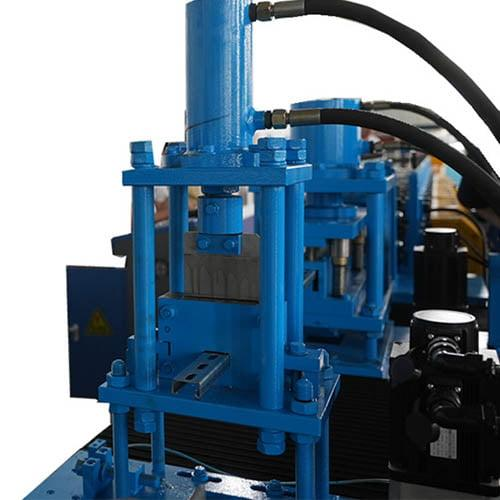

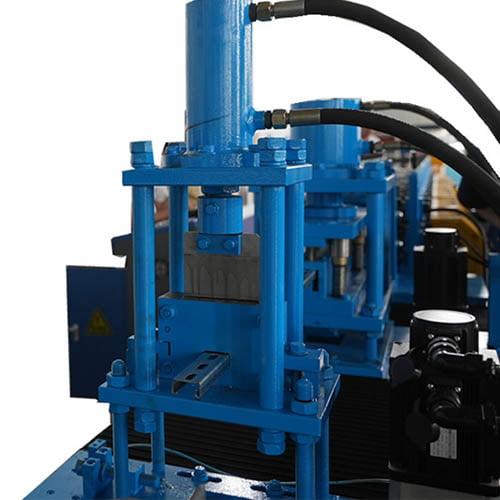

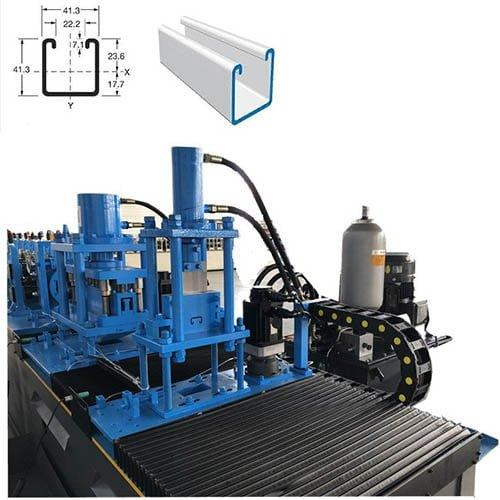

STRUT CHANNEL ROLL FORMING MACHINE

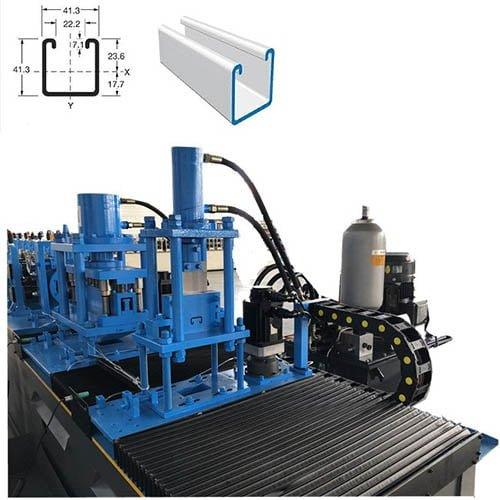

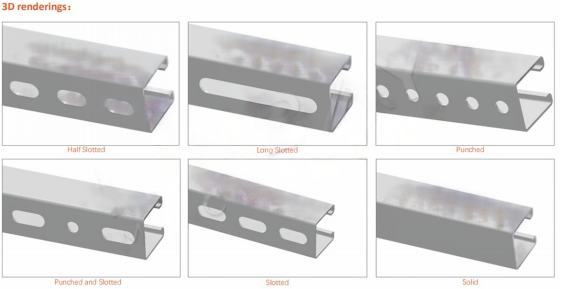

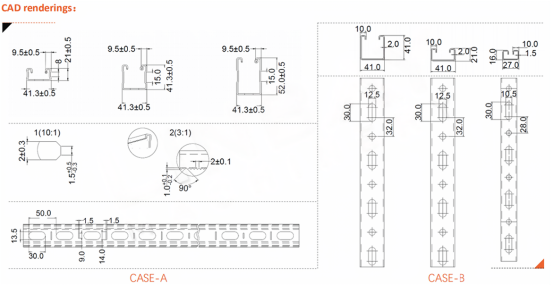

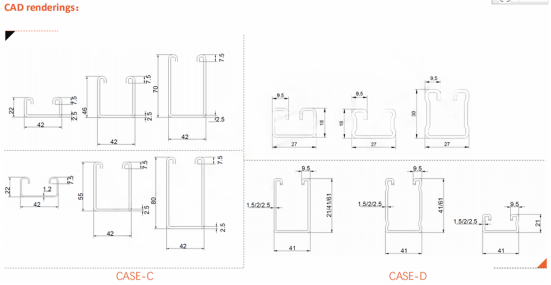

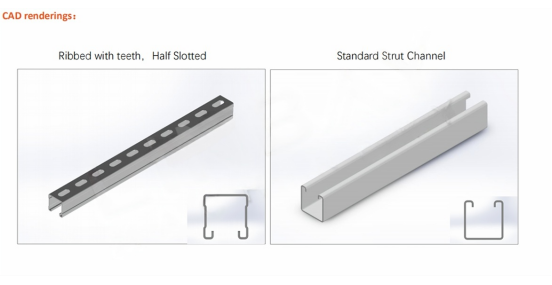

Strut channel roll forming machine has two main application: One is also called like seismic support roll forming machine or seismic channel roll forming machine, its product is used to mount, brace, support, and connect lightweight structural loads in building construction. Other is called solar rack roll forming machine or photovoltaic (PV) rack roll forming mahcine, its product is used in PV support bracket. Our strut channel roll forming machine is suitable to produce strut channels with 12 gauge ( 2.6mm ) or 14 gauge ( 1.9mm ) thick sheet metal ( normally range 2-2.5mm ), raw material could be Hot-rolled and cold rolled steel, Hot-dip galvanized sheet, PreGalvanized Steel, Mill ( Plain/Black ) Steel, Aluminum, Stainless Steel etc. And according to slot type, our machine could produce solid channel, slotted channel, half slotted channel, long slotted channel, punched channel, punched and slotted channel etc.

Application

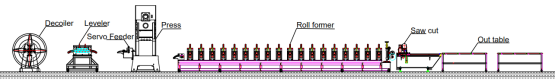

Working Process Of STRUT CHANNEL ROLL FORMING MACHINE

This strut channel production line is made for our Pakistani customer finished in 2018. This is a similar line of SAMCO, Canada using flying hydraulic punch and flying hydraulic cut, it means non-stop punch and non-stop cut. Normal working speed reach 20m/min. Also we suggest you a rotary punch, whose speed can realize 40m/min if you want a higher-yield production line.

STRUT CHANNEL ROLL FORMING MACHINE

Technical Specifications

Machinable Material : | A) Hot-rolled and cold rolled steel | Thickness(MM): 1.8-2.6 , 2-2.5 |

B) Hot-dip galvanized sheet | ||

C) Pre-Galvanized Steel | ||

D) Mill(Plain/Black) Steel | ||

E) Aluminum | ||

F) Stainless Steel | ||

Yield strength : | 250 - 550 Mpa | |

Tensil stress : | G250 Mpa-G550 Mpa | |

Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

Punching system : | Hydraulic punching station | * Punching press (Optional) |

Forming station : | 20-22 | * According to your profile drawings |

Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

Driving system : | Gearbox drive | * Chain drive (Optional) |

Machine structure: | Forged Iron station | * Wall panel (Optional) |

Forming speed : | 15-20 (M/MIN) | * Or according to your profile drawings |

Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

Cutting system : | Post-cutting | * Pre-cutting (Optional) |

Frequency changer brand : | Yaskawa | * Siemens (Optional) |

PLC brand : | Panasonic | * Siemens (Optional) |

Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

Machine color : | Industrial blue | * Or according to your requirment |

Images: