Solar Purlins Roll Forming Machine C40-C160 Automatic Changeover

Strut channels, also known as strut channels or metal framing channels, are widely used for structural support in various applications. The roll forming process plays a crucial role in producing high-quality strut channels with precision and efficiency. We will discuss the importance of strut channels, the roll forming process, and the advantages of utilizing strut channel roll forming machines in manufacturing operations.

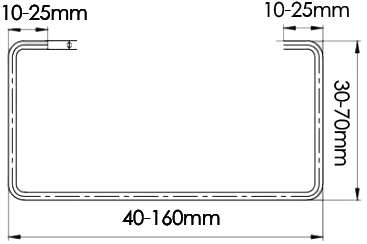

Here is a profile pictures:

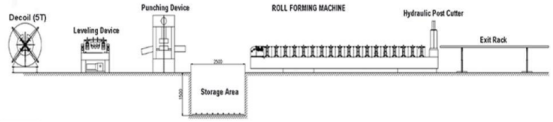

Work flow of Solar Purlins Roll Forming Machine C40-C160 Automatic Changeover:

Hydraulic Decoiler→Feeding And Leveling Device→Hydraulic Punching& Pre-Cutting Device →Roll Forming System→ Servo Controlled Post Cutting→Exit Rack

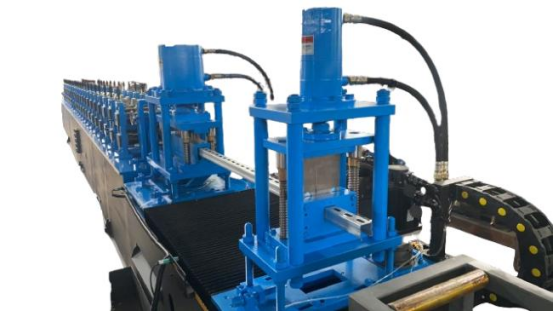

Solar Purlins Roll Forming Machine C40-C160 Automatic Changeover

Features

1.ZTRFM heavy-duty design,whole machine weight more than 20tons,gearbox transmission (high transmission efficiency and accurate transmission ratio) , machine service life more than twice that of other Indian and Chinese cheap machines.

2. One machine for multi-profiles: any C purlin within web range 40-160mm, saving investment and space .

3. Allows you to offer clients 24-hour customized C purlin service an various gauges of material, this includes different widths and flange height combinations.

4. Servo motorized automatic changeover for different C purlinswithin 1-5 minutes, saving time and improving work efficiency.

5.Eight-cylinder punching system can meet various punching holes requirements of the solar industry.

6. European cast steel forging structure with anti deformation and high load bearing capacity, ensures the machine forming accuracy.

7. Servo Controlled Precision Flying Post Cut Off System (for high working efficiency).

8. The latest PLC control system is adopted to ommbine two sets of length counting methods ( infrated counting-hole length counting and encoder-counting-wheel length counting) into one PLC control system.The length counting method can be switched to solve the problem of incompatibility due to the special length of individual orders.

9. Equipped with water cooling system to cool the roller and profile, extend the service life of roller and ensure the quality of finished profiles.

Specifications

Material | Applicable material | Galvanized Steel(GI),Cold roll steel(CRC) |

Material thickness | 2.0-4.0mm | |

With yield strength | Q235-550Mpa | |

Coil | Feeding width | According to the drawing |

Coil ID range | 508mm±30mm | |

Capacity | Max. 5 Ton. | |

Machine | Base Frame | European free standing structure |

Roller Material | Cr12 steel, precision machined,hard Chrome Coated | |

Roller station | 22-steps to form | |

Shaft diameter | ф95mm,High Frequency Processing | |

Cutter

| Hardness | Heat treatment to HRC58-62 degree |

Cutting tolerance | ≤±1mm | |

Power | Driving way | Gear/Sprocket transmission |

Main motor | 30KW,Frequency Speed Control | |

Pump motor for cutter | 22KW | |

PLC Control System

| Inverter | Siemens / DELTA |

Touch Screen | Siemens/WEINVIEW | |

Encoder | KOYO (Japan brand) or OMRON (Japan brand) | |

Control Voltage | 24V |

1) 5 Ton Hydraulic Decoiler:one set

Hydraulic Control Steel Coil Inner Bore Shrinkage And Stop

Max. Feeding Width:600mm

Coil ID Range:508±30mm,Outside Diameter:1600mm

Max Capacity:5 ton,Motor:3KW,Frequency Speed Control

Oil Pump Motor:2.2KW,With Press Arm

Add Automatic Feeding Power And Self-Stop Device

2) Feeding and Leveling Device

Up Three Down Four Totally Seven Shafts Leveling Device

Shafts Manufactured From GCr15 Steel(=EN31 Steel)

Heat Treatment,HRC 58-62.Diameter=φ105mm

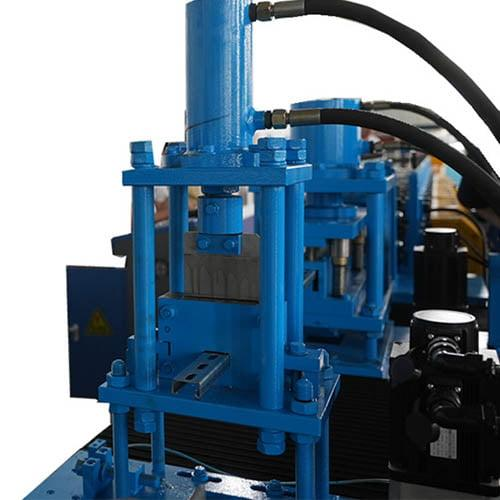

3) Hydraulic Pre-Cutting & Punching Device

Pre-punching and Pre-Cutting, use the same hydraulic system

Hydraulic Motor:22KW,Hydraulic Pressure Range: 0-16Mpa

Punching And Cutting Tool Material:Mold Steel Cr12MoV(=SKD11 steel

With One Million Times cutting Life),Heat Treatment To HRC58-62 Degree

8-cylinders Hole Punching System For Punching Both On Web And Flange

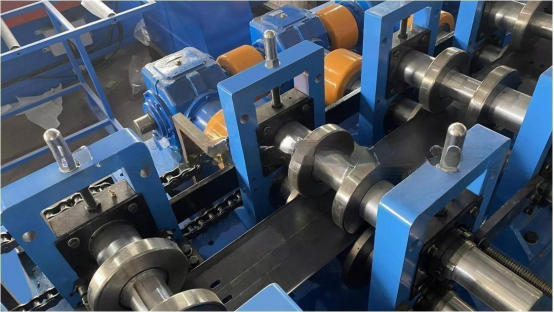

4) Main Machine

Rollers manufactured from Cr12 steel, precision machined,hard Chrome Coated

Shafts manufactured from 45# steel,Quenching and tempering , hard chrome

Real forming speed:15-20m/min(including punching and cutting)

5) Servo Controlled Post Cutting

45 Degree Hydraulic Oblique Sear: Short Shearing Stroke, Small Cutting Resistance And Fast Shearina Speed

6) PLC Control System

Control The Quantity And Cutting Length Automatically.

Input The Production Data(Production Batch,pcs,Length,etc.) On The Touch Screen.

It Can Finish The Production Automatically.

Combined With: PLC, Inverter, Touch Screen, Encoder, etc.

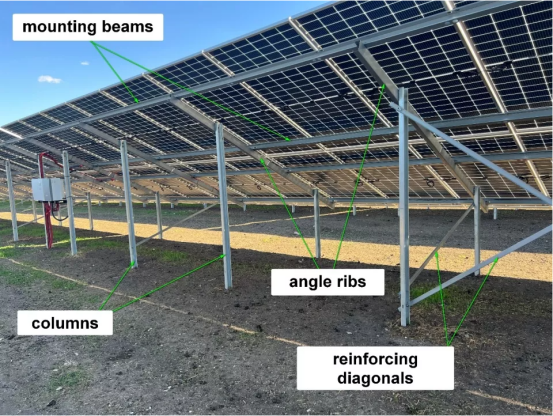

Application Case