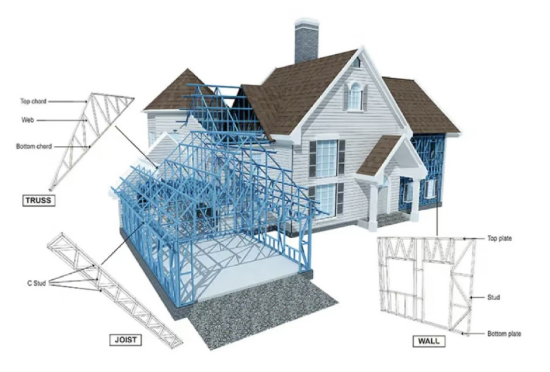

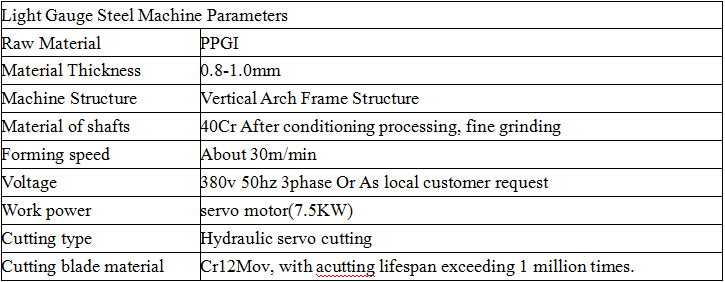

Description:Good Performance G550 Z275 0.8-1.2mm Light steel frame machine What is the investment prospect of light steel frame machine? light steel frame machine (also known as LGS frame machine) is used for LGS structure houses. The profiles used in this kind of house are produced by cold bending forming methods. These profiles are assembled into a structural steel frame by screws and bolts at the construction site, and can also be applied to various wall and floor structures.

Light Gauge Steel Villa Frame Keel Roll Forming Making Machine

Good Performance G550 Z275 0.8-1.2mm Light steel frame machine What is the investment prospect of light steel frame machine? light steel frame machine (also known as LGS frame machine) is used for LGS structure houses. The profiles used in this kind of house are produced by cold bending forming methods. These profiles are assembled into a structural steel frame by screws and bolts at the construction site, and can also be applied to various wall and floor structures. After the frame has been lapped, the building can be completed by installing an outer layer of insulating material or painting concrete. The system can be applied to all characteristic types of buildings, such as schools, residences, offices, hotels, hospitals, factories and warehouses, etc. Different types of profiles produced by light steel frame machine can replace wood in residential and light commercial buildings. It is very suitable for load-bearing walls and interior rooms. The frame is very similar to wood, and because the positions of the screw holes on the profiles are produced through rigorous calculations, there is almost no need to spend time on drilling and determining the hole distance at the work site. Due to its light weight, transportation is more convenient and costly. The profile size is fixed, the installation method is simple, and the construction speed is fast. And because it is made of metal, light steel structure houses will not rot, split, warp, shrink, burn, or be eaten by termites. Compared with wooden frames, steel frames generate less on-site waste, thereby reducing the cost of debris removal. In addition, because waste is used in recycling facilities, waste can even generate some revenue to offset project costs.

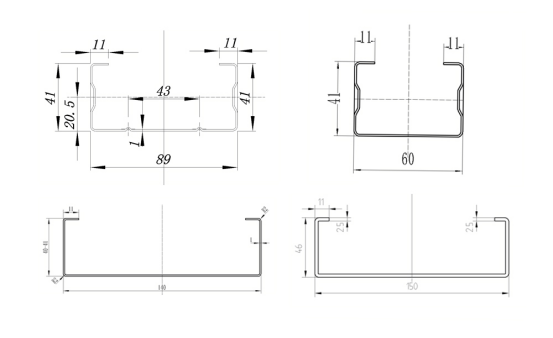

Profile drawing for reference:

Light gauge steel is suitable for residential, commercial, industrial, and temporary structures, offering advantages of rapid assembly, flexible customization, and strong durability.

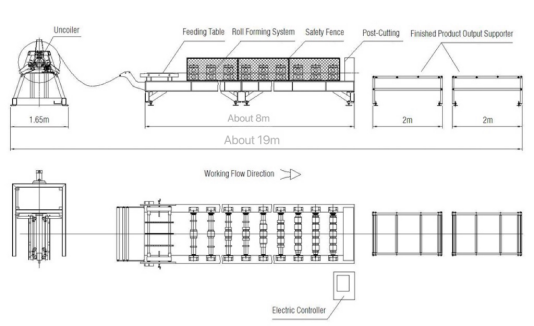

Processing Flow:

Decoiler -Feeding-Material-Roll Forming-POST Cutting-Finished Product Output Supporter

Light Gauge Steel Villa Frame Keel Roll Forming Making Machine

The advantages of a Light Gauge Steel Machine include:

1. High Efficiency Production: Light gauge steel machines can rapidly and efficiently produce components of light steel structures, enhancing production efficiency.

2. High Precision: These machines can accurately cut, punch, and shape light gauge steel materials, ensuring precise dimensions and shapes of components.

3. Flexibility: Light gauge steel machines can produce various sizes and shapes of components as needed, offering high production flexibility.

Decoiler

1.Loading capacity: 1.5 tons

2.Expansion or contraction method: Operate the handle so that the four connecting rods move away from or towards the center axis.

3.Brake: The center shaft is double clamped, prevents forward inertial motion when stopped suddenly.

4.Driving method: unwinder raw material automatically

5.With feeding and leveling device. 6. Feeding device with four guide rollers

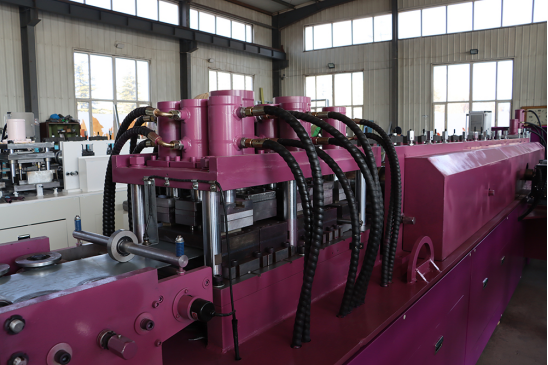

Punching System

1.Punching Hole Types: Rivet holes,countersunk holes, pass-through elliptical holes.

2.Punching Hole Diameters: 3.5mmrivet holes, 16.5mm threading holes.

3.Punching Die Models: A standard setwill be established after confirmingthe base width data. The servo motor drive makes the punching position more accurate

Roll Forming Device

1.Main Shaft Diameter: p80mm. made of 45# round steel.

2.Roller Material: Heat-treated, precisionmachined, chrome-plated, mirror-polished.

3.Cold Bending Forming: The process of coldbending steel material coils into shape.

4. Arch structure: more stable, can produce higher precision products

Hydraulic Cutting Device

1.Guiding Mechanism:Upper andlower cutting devices ensure smoothand deformation-free cuts.

2. Blade Material: Cr12Mov, with acutting lifespan exceeding 1 million times.

PLC control system

1.Function: Design parameters can be directly transmitted to the control computer via USB interface or network, where the installed NC control software automatically imports and reads the BOM (Bill of Materials) upon selection of the production batch.

2.Control method: One 17-inch touchscreen computer + electrical main control cabinet.

3.Main components origin: PLC (Panasonic), relay (Schneider Electric, France), length encoder (OMRON), servo motor (INVT).

Application