Description:In good quality, be rooted on credit history and trustworthiness for growth, will keep on to provide previous and new customers from home and overseas whole-heatedly for Drum Locking Ring Machine, Steel File Cabinet Post Machine, Furniture Frame Manufacturing Machine. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We focus on creating value for users, not chasing short-term profits and superficial prosperity, but with equal and friendly communication.

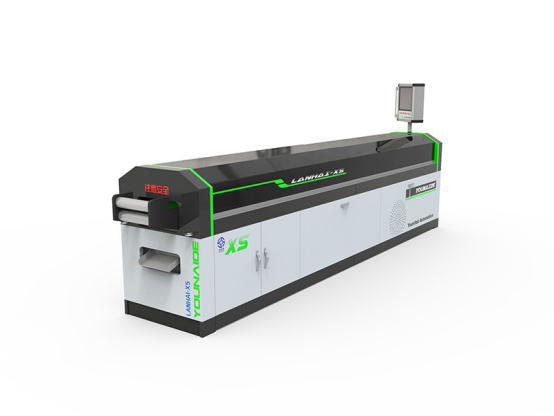

Product Details of C89 Light Gauge Steel House Lgs Framing Roll Forming Machine for Villa

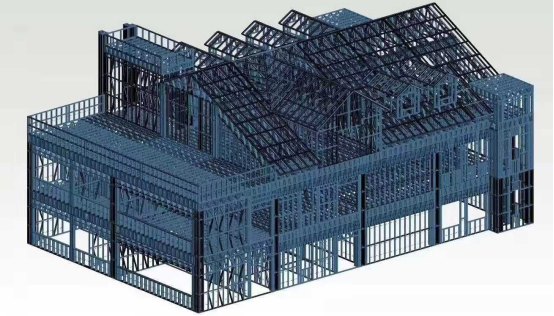

Light gauge steel frame roll forming machine is suitable for high-strength cold roll former light-steel structure building forming machinery and equipment system is a forming equipment system designed for specific building manufacturing enterprises.And this machine integrate of component production and manufacturing,achieving high automation, efficiency, high quality, and high speed.

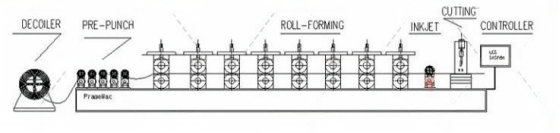

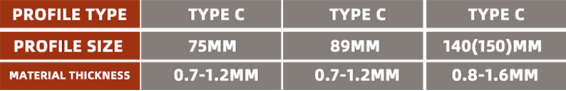

Profile drawing for reference:

Working Flowing

Manual Uncoiler --Feeding--Roll Forming--Cutting--Output Table

Product Details of C89 Light Gauge Steel House Lgs Framing Roll Forming Machine for Villa

Components Of this Machine:

-The servo motor

-Hydraulic system

-Colding system

-Digital control system

The LGS roll forming machine enables the intelligentization of architectural design, production

and processing, construction, and installation by integrating a full version of the design software

and seamlessly linking the equipment system and the software.

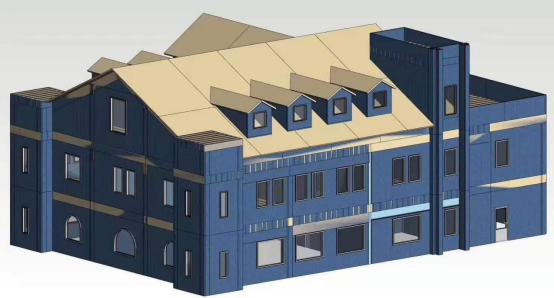

Suitable for building:

Express lodgings, car clubs and hotels, civil dwellings, low-cost housing, and agriculture;

rehabilitation of housing in pastoral and forestry areas and housing for employees' dormitories;

making cold-formed thin-walled commercial and industrial buildings, trusses, mobile homes,

modular homes, and other structures buildings with steel frames, etc.

The light gauge steel profile produced by the 89 type light steel gauge keel machine has the characteristics of the industry and can be installed quickly and quickly. The ZTRFM light steel profile design software integrated with the standard 89 type light steel keel equipment production system conforms to the developed building codes of Australia and New Zealand and the cold-formed thin-wall light steel (LGS) structure design standards.

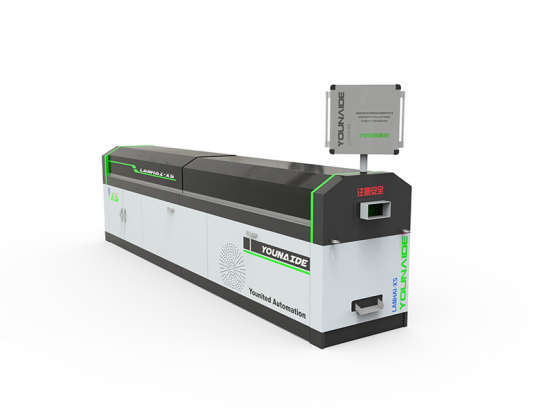

Parameters Of Machine

Material | Galvanized coil |

Material thickness | 0.5-0.9mm |

Power of main forming machine | 5.5KW |

Forming speed | 25-30m/min |

Size | 6*0.7*0.8mm(length*width*height) |

Advantages Of This Machine

Fast running speed : 300-900m/1 hour, 4-6T/8 hours and the mold is large

and the discharge speed is faster

High precision: the accuracy is within ±0.5mm

High quality: SKD11 mold can be used more than 3 million times

Cost saving, no waste: the hole position is accurate and easy to install and precision machining of mechanical parts, quiet and energy saving12 sets of roll forming, stronger and more stable performance, straighter output, no deformation of the product

Independent mold, easy to maintain

Use imported accessories, stable performance, low failure rate

No wear on the surface of the keel material

After-sales support, installation and commissioning, 1-year warranty,

lifetime maintenance

Free housing design, equipment operation training

Cooling device, longer equipment life

Touch screen control, easy operation, clear production status at a glance

Intelligent full-automatic system, automatic identification of house drawings and production documents for production, no special requirements for operators

Die combination (web through hole, dimple screw hole, wire tube hole, foot hole, chamfer, small edge cutting)

The product is seamlessly connected, the world and the vertical bones are seamlessly connected

Double load bearing. The heaven and earth bones and screws achieve double compression, making it stronger

All accessories support universal, no technical barriers.

The thickness of the compressible product is between 0.8-1.2

Application