C Purlin Roll Forming Machine

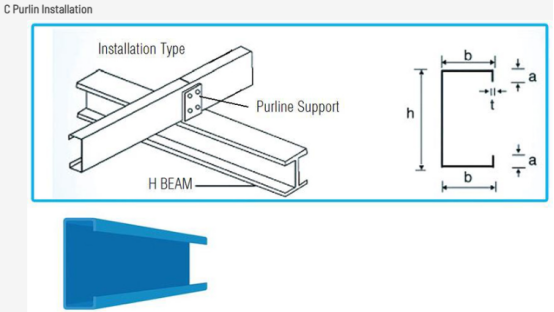

C-shaped steel is widely used in purlins and wall beams of steel structures,and can also be combined into lightweight roof trusses and brackets.In addition,most C channel purlins for sale can also be used for columns,beams,and arms in the manufacture of mechanical light industries.As the features of green,solid,economical,durable,fast&easy to install and good looking,steel purlin and other steel building materials are used more and more widely.

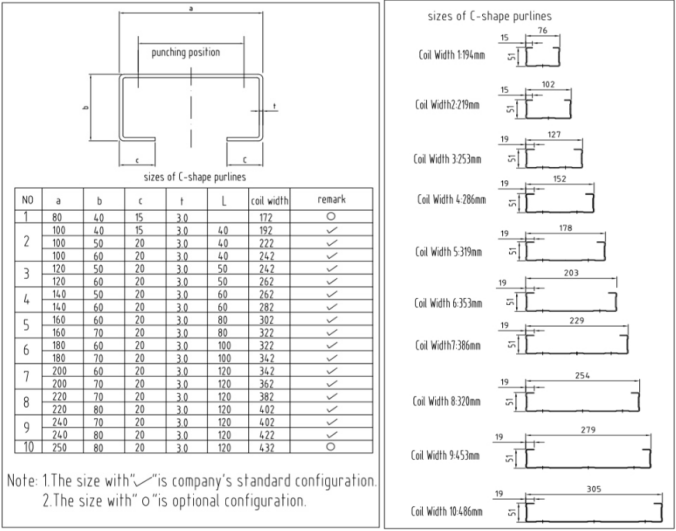

Here Is The One Drawing Profile For Your Reference:

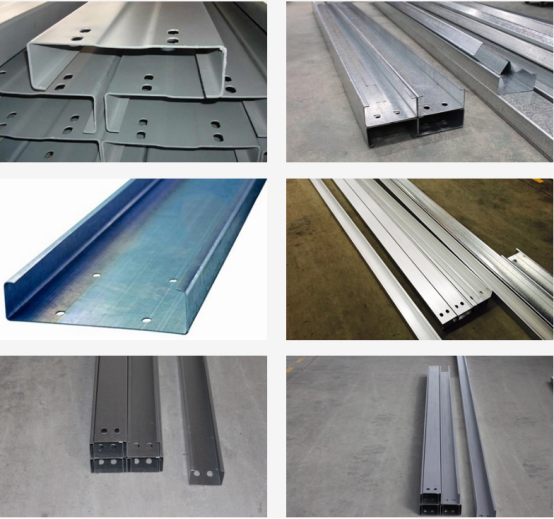

C purlin images

The below C purlin images will show you some finished C purlin panels completed by our C-purlin roll forming machines.

Working flow of C purlin roll forming machine

Pre-cutting flow:

Decoiler(passive/auto)→Feeding and Guiding table→leveling system→hole punching system(as profile requests)→pre-cutting to length→roll forming system→output manual supporter/Auto stacker(optional)

Post-cutting flow:

Decoiler(passive/auto)→Feeding and Guiding table→leveling system→hole punching system(as profile requests)→roll forming system→post-cutting to length(hydraulic)→output manual supporter/Auto stacker(optional)

C Purlin Roll Forming Machine

Features and advantages of C Purlin Roll Forming Machine

Fully automatic continuous C profile purlin roll forming machine for both heavy and light-duty use.

Adopts changing spacers to make multi sizes profiles sections.

Inline flexible punching system integrated.

Pre-cutting and post cutting is optional:If need to produce many sizes,we can adopt pre-cutting to save cost and much time on changing blades during change sizes.

If profile sizes are not so many,post-cutting can improve profile quality greatly.

Forming speed:12-15m/min

For most hot&popular models,we have C purlin forming machines in stock for prompt delivery.

Suitable coll sheet material for C purlin roll forming machine

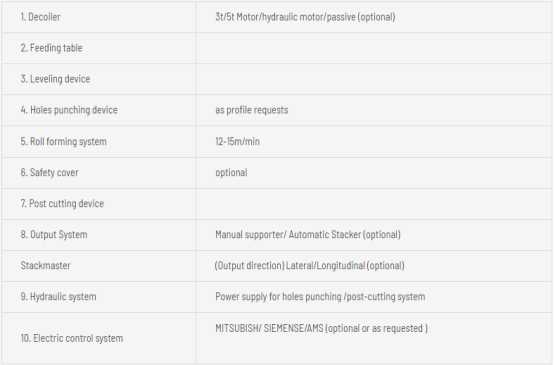

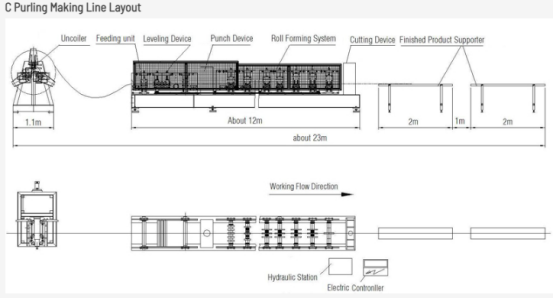

Production line components and parameters of C roll forming machine