Description:As the features of green, solid, economical, durable, fast & easy to install and good looking, Z-shaped steel purline and other steel building materials are used more and more widely. The Z purlin panels are suitable for suits various light steel structure construction, civil construction, and mansions buildings.

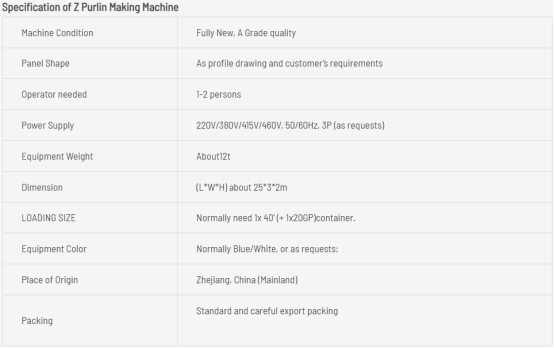

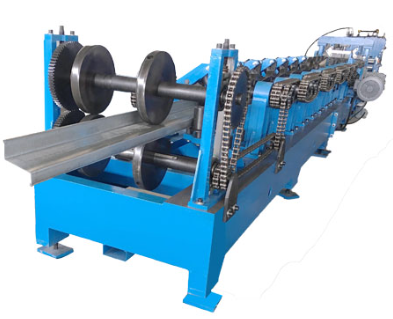

Z Purlin Roll Forming Machine

Z-shaped steel is a common cold-formed thin-walled steel with a thickness of 1.6 3.0mm and a cross -sectional height of 120-350mm. Cold-formed Z-shaped steel has the advantages of adjustable size and large compressive strength. It is widely usedin automobiles, railway vehicles, building doors, and windows, transportation, shelves, electrical cabinets, highway guardrails,building steel structures, containers, steel formwork and saffoling, solar energy Bracket shipbuilding, bridges, transmissiontowers, steel sheet piles, cable trays, agricultural machinery, furniture, storage, guide rails, keel steel, vegetable greenhouses,pipeline supports, municipal construction, and other fields.

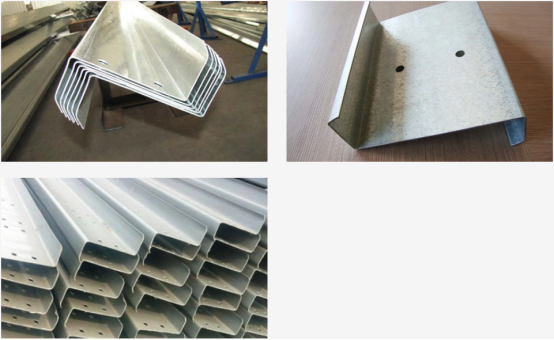

Z purlin panels

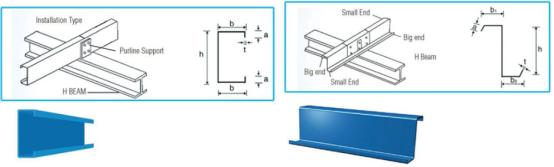

Z purlin installation

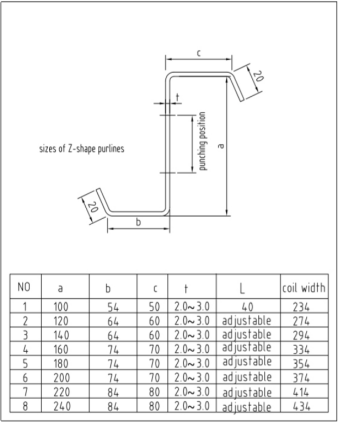

Popular Z profile drawings

Z Purlin Roll Forming Machine

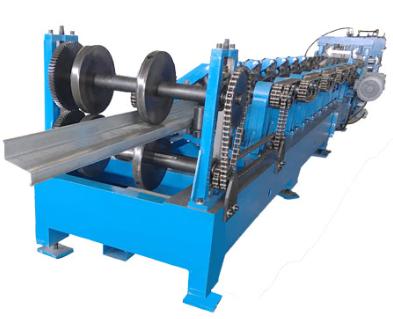

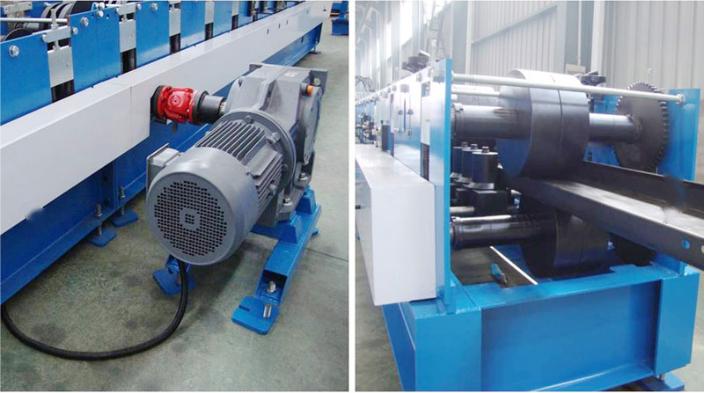

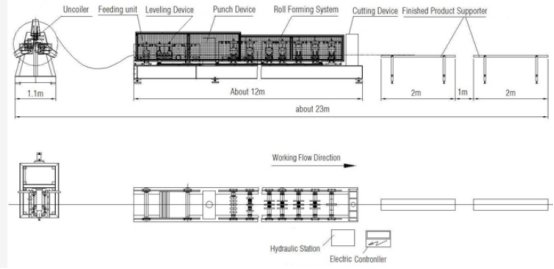

Working Flow of Z Purlin Making Machine

Pre-cutting flow:

Decoiler (passive/auto)- Feeding and Guiding Table - leveling system - hole punching system (as profile requests) -pre-cutting to length - , Roll Forming System , Output Manual Supporter/Auto Stacker(optional)

Post- cutting flow:

Decoiler (passive/auto) - - Feeding and Guiding Table -leveling system = hole punching system (as profile requests) - T RollForming System - Post Cutting to length (Hydraulic)- Output Manual Supporter/Auto Stacker(optional)

Suitable Coil Sheet Material of Z Purlin Making Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 2.0-3.0(mm)

Yield Strength: 230-300 (MPa)

Width: lt can be made in accordance with your own requirements

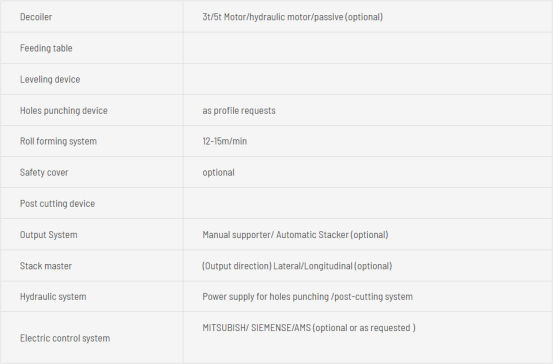

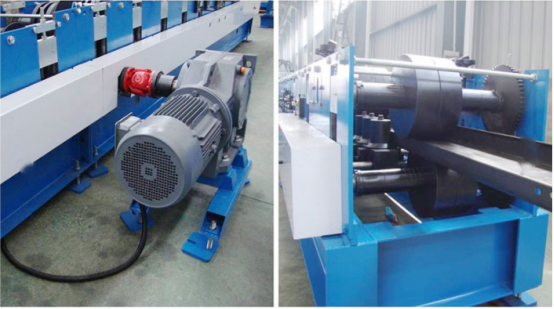

Production Line Components and Parameters of Z Purlin Making Machine