Description:

The CZ purlin machine is 90% automatic degree, sizes changing automatically, C and Z change automatically, servo motor high speed driving, Machine only use pre-cutting system, no post cutting system.

Advantage: Machine cutting No waste material, pre cutting machine is faster than post cutting machine. Pre-cutting machine no need adjust the cutting blades.

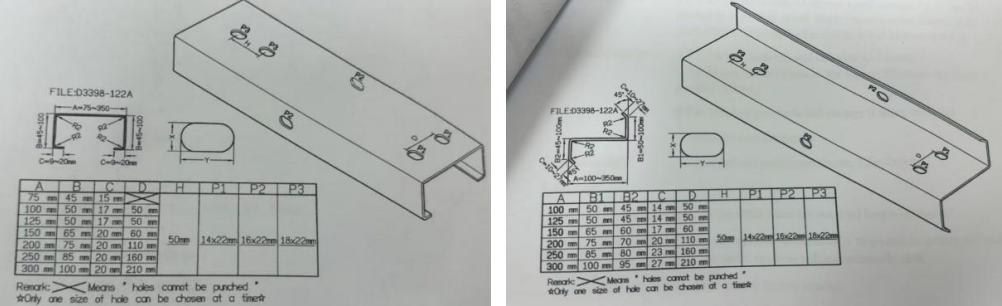

Product requirement:

Thickness:1-3.5mm

Yield strength: 350Mpa

Width: 80-350mm

Flange:30-100mm

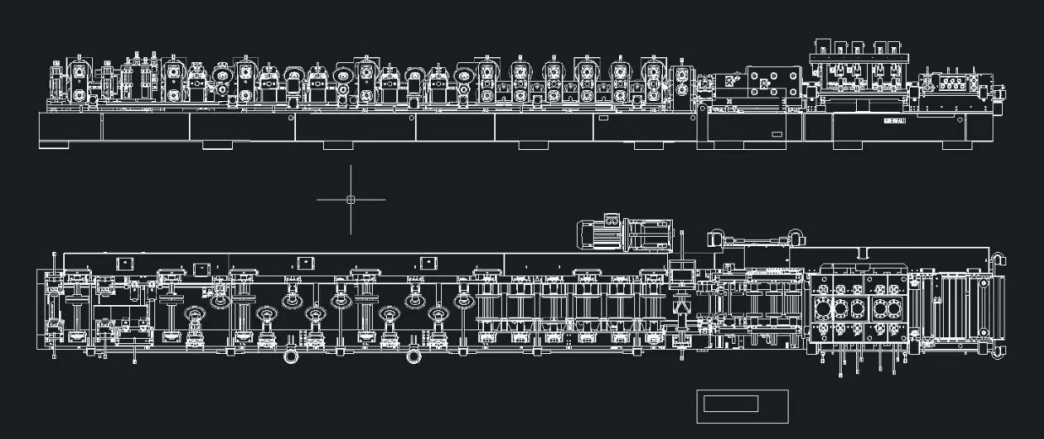

Machine flow drawing:

Uncoiling → Feeding material into machine →Leveling → Punching and Pre-shearing →Roll forming →Products receiving table

Main components:

6 ton hydraulic decoiler

Main roll forming machine

PLC control system

Hydraulic station

Receiving table

Main Parameter:

1. Feeding and leveling part

Leveling rollers: 3 up 4 down

Roller material: Cr15

Roller diameter: 75mm

Feeding width adjustment: automatic by button

Make sure inputted steel sheet straight and neat and then roll forming process could be made accurate

2. Punching and pre shearing part

Punching unit with hydraulic system;

Punching mold:Gcr12 quenched treatment

Station 1: Bottom center holes punching

Station 2: Bottom double side holes punching

Station 3: Bottom double side holes punching

Station 4: Bottom double side holes punching

Station 5: Pre-Hydraulic shearing

3. Mian roll forming part

Roller material:

Cr12 CNC processing heat treatment to

HRC: 58-60 ,finish turning

Roller stations :22 rows

Diameter of shafts:Φ75 mm solid

Material of shafts:

40 Cr CNC processing

HRC28-32 ,finish turning and electroplate

Forming speed: max 37m/min

Voltage: 380V/50HZ/3P (as requested)

Transmission way :

Double chains + shaft end support

Servo motor power: 42 Kw

Sizes changing: by Laptop / Electric button

C and Z purling change : automatically control by PLC

4. Hydraulic station

Punching and shearing use the same one hydraulic tank.

Tank volume: 300 liters

Hydraulic oil: 46#

Hydraulic station power: 15KW + air cooler

If you have other problem or something can’t understand clearly, please let me know.

Contact information:

Email: cnzt011@zhongtuocn.com

Whatsapp: 0086 18631755623

Contact person: lee