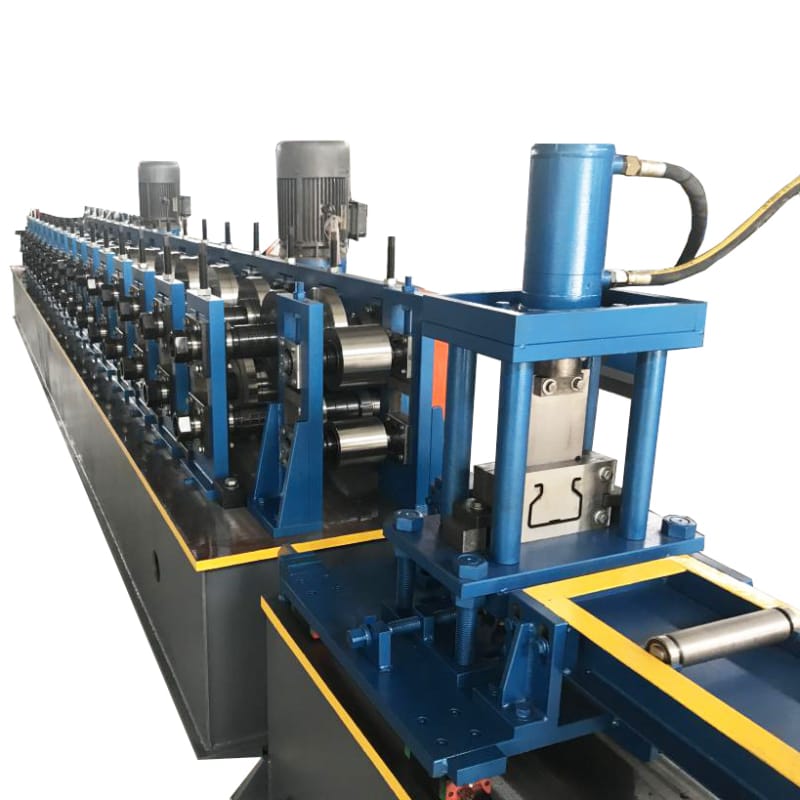

Selective Pallet Racking rolling forming machine

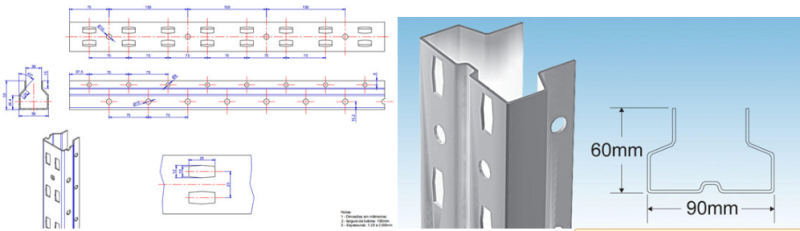

Selective Pallet Racking rolling forming machine is designed to make the pallet racking part in batch fully automatically. Selective Pallet racking is the most widely used storage pallet rack, consisting of frame, beam and other components. The frame is assembled by uprights and bracings and beams are fixed to uprights by hooks. The height of each layer can be adjusted by 75mm, the capacity of each layer can be up to 4500kg. It’s convenient to load and unload pallets with goods on by using forklifts; Such forklifts as front-move forklift, balance-weight forklift, common forklift and stackers can also be used. The system is composed by many elements, here I will take the rack pallet drawing profile for example to show you how the machine is designed, in the following part,we will show the beam rolling forming machine, shelf panel rolling forming machine and other bracing element.

Selective Pallet Racking System:

Selective Pallet Racking rolling forming machine design:

Selective Pallet Racking rolling forming machine machine elements | ||

1 | Hydraulic decoiler | 1 set |

2 | Punching system | 1 set |

3 | Coil feeder | 1 set |

4 | Leveling Machine | 1 set |

5 | Roll Forming | 1 set |

6 | Hydraulic Cutting | 1 set |

7 | PLC Control System | 1 set |

8 | Hydraulic Station | 1 set |

9 | Run-out Table-(Un-powered) | 1 set |

Main forming machine : 1) Forming steps: 18 steps 2) Outer diameter: 70mm 3) Machine frame (type): memorial arch frame, Thickness of memorial arch frame: 30mm 4) Roller information: B. Quenched degree: 56-58°C 5) Shaft material: 45# steel with heat treatment and hard chrome plated on the surface 6) Main motor power: 18.5kw, Reducer ratio: 1:14, Reducer Type: Hardened reducer 7) With cooling device | ||

Selective Pallet Racking rolling forming machine Cost effect elements:

For giving the quotation exactly, here we share some points which will effect the cost of the rolling forming machine.

1. Which type decoiler you like to choose, hydraulic decoiler or manual decoiler.

2. The leveling beach accurately leveling or just the normal type.

3. The main rolling forming machine part, we use the gearbox type or the gear type or the chain transmission.

4. The frame you choose molding frame or middle plate frame.

5. The shearing part you choose flying tracking shearing or jus the hydraulic shearing.

6. The receiving table you choose the manual type or the automatic type.

7. The rollers you choose Gcr15 or SKD11.

8. And the most important the punching machine which type to choose. We use the hydraulic punching station, or world famous punching machine.

And there more elements like speed and automatic degree, all will effect the machine cost.

Now let us check more details if the Selective Pallet Racking rolling forming machine:

Normally we design the machine using the following punching machine. If you feel this type price is higher and then you can choose the normal brand or other brand, no matter how we also buy from the market.

For this machine, if you want to know more information, please contact us at any time. Here is the machine working video for your reference: