Sigma Purlins M purline rolling forming machine

Purlin roll forming machine is the most popular and has an extensive use in the construction work. Sigma Purlins M purline profile, we can design according to the size range, thickness range and give the different solutions of purlin roll forming machine to manufacturer a complete range of structual purlins(height and width change using automatic system by motors): In the market, the most popular is C/U/Z/M section-manual change 4 stations from C to Z, change time: 2 minutes

C/U/Z/M section-automatically change from C to Z, change time: few seconds. But this design, the cost will be a little higher. Here I will share a more economic design which only can produce M purline, by this way we can save the cost:

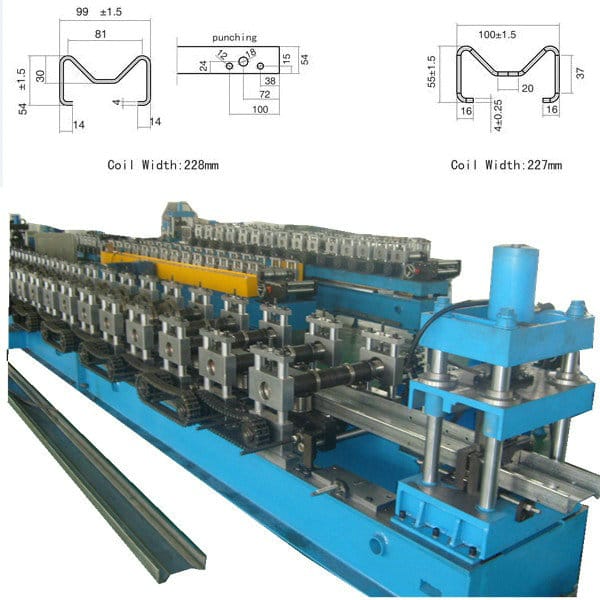

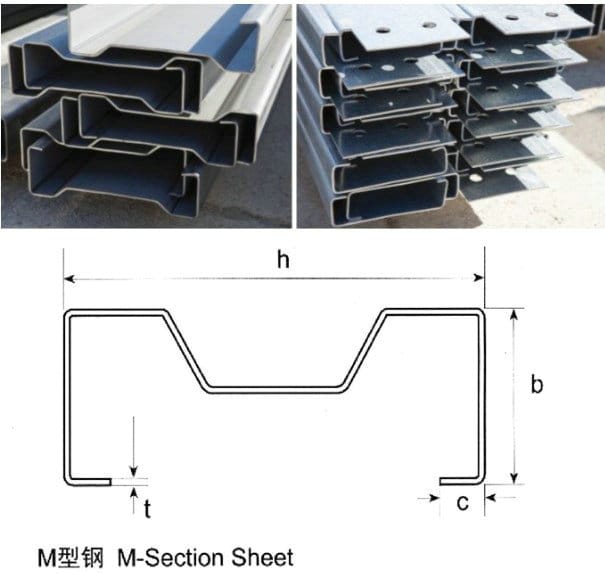

Sigma Purlins M purline drawing profile for your reference:

Here is just one size for your reference, by manual adjustment, the production line can produce more sizes meanwhile the cutting blades also needed to be changed also.

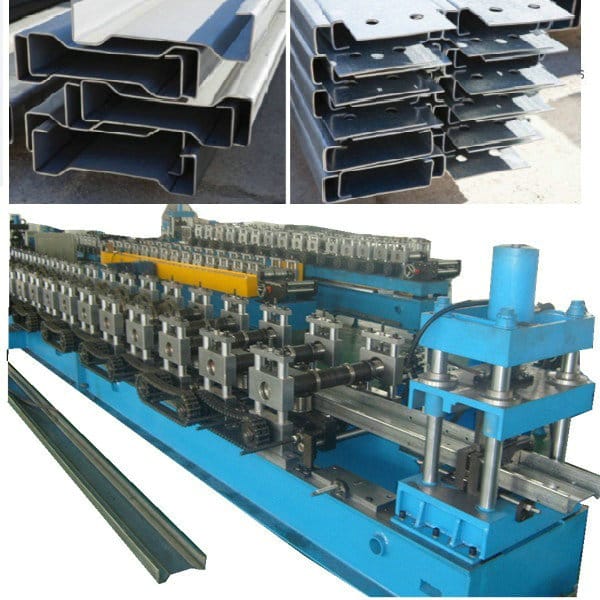

Sigma Purlins M purline rolling forming machine manual adjustment type for your reference:

Sigma Purlins M purline rolling forming machine working flow:

Uncoiling---guiding---feeding&flatting---forming---punching&cutting---product receiving

M purline roll forming system | ||

Roll forming system | Guiding roller | Two pcs |

Diameter of 40mm | ||

Tempering treatment | ||

Usage: to let the sheet feeding into next device in the right position | ||

Feeding&flatting device | 5 pcs | |

Diameter of 70mm | ||

Tempering treatment | ||

Usage: to feed the sheet into forming system positively and remove the sheet radian from coil, avoid the product curve and keep straight | ||

Rolling shaft | Shaft material: 45# steel | |

Shaft diameter: 80 mm | ||

Tempering treatment | ||

Roller | Roller material: Cr15 | |

Quenched treatment | ||

Rolling station number | 15 stations | |

speed | Working speed: 0-25 m/minute without punching and 0-12 m/minute with punching | |

Machine frame | Carbon steel welded structure | |

Machine body | steel plate welded with grinding | |

Bearing | Chinese famous brand Harbin | |

Work power | 15 kw | |

Transmission | By chains | |

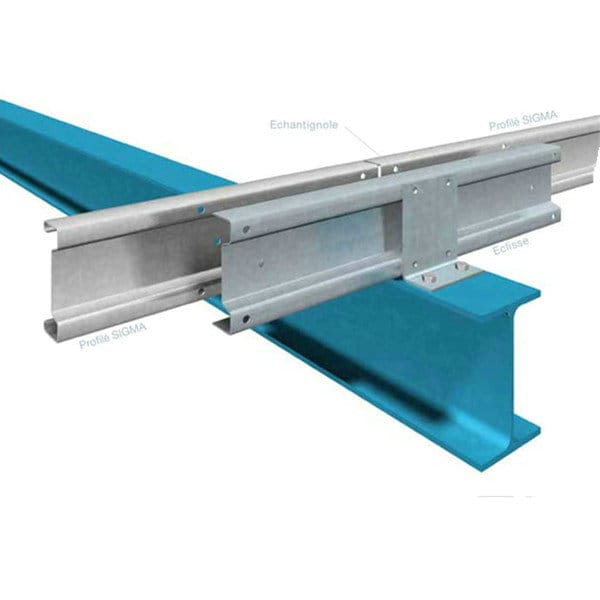

Where to use the M purline:

Roof purlins:

Use sleeves to shorter purline or assemble 2-span purline staggered

Keep a space of approx. 15 mm between the truss and the purlin

Eaves beams are supplied with an angled top flange, so only 1 profile is needed where roof and wall meet

Options of CUM purline fully automatic type, we will share in next article. For more information, please contact us at any time.