Angel Steel Frame Making Machine

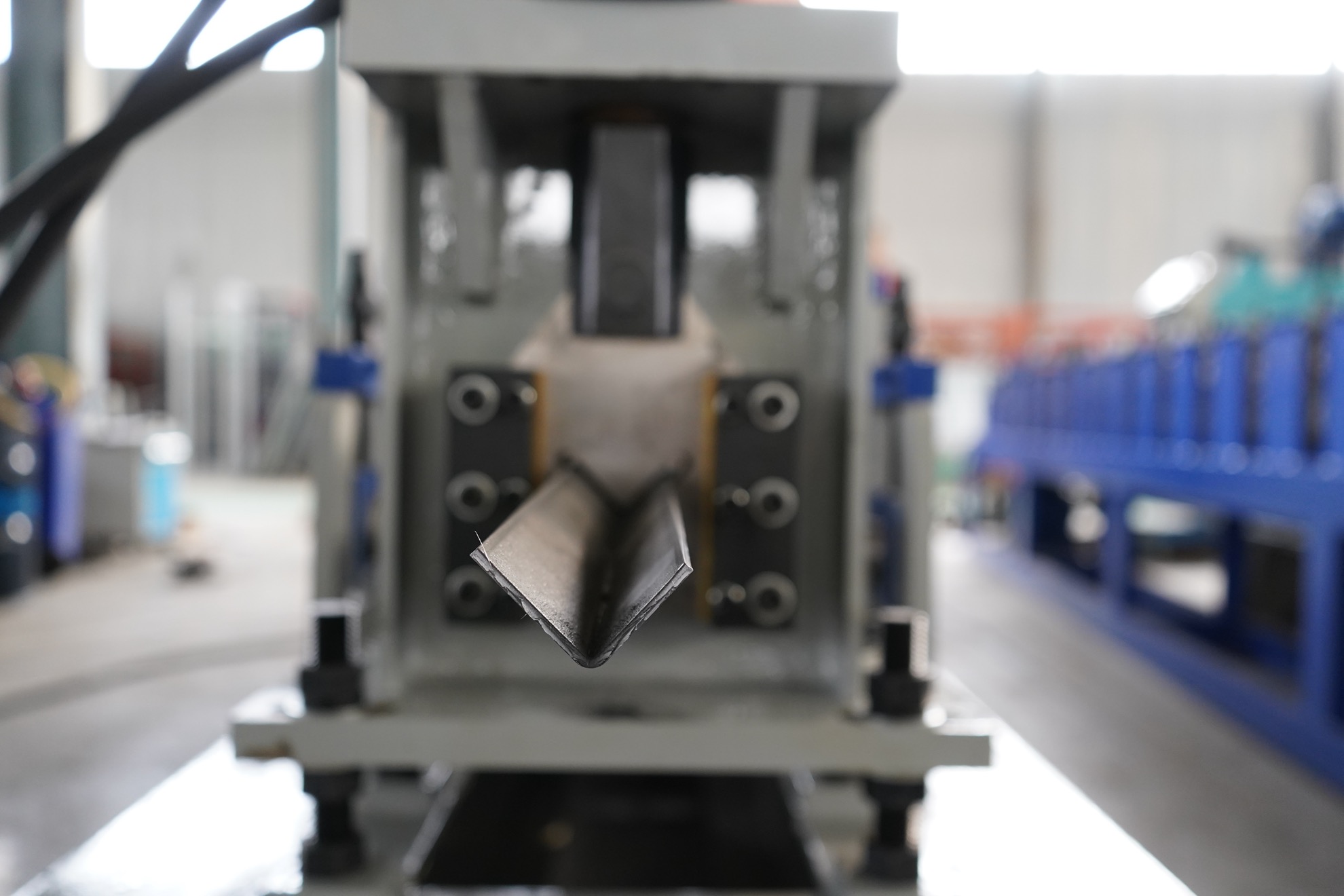

Angle steel frame making machine is a type of building machinery channel forming machine. The main categories of finished products include equilateral angle steel (conventional symmetrical structures) (mainly used in partition wall construction, shelves, and towers), unequal angle steel (mainly used in asymmetric load-bearing scenarios, such as special mechanical supports), and thickened angle steel (like section steel used for load-bearing, mainly used in the construction of steel structure buildings). The forming process of angle steel is relatively simple. Angle steel frame making machine can adjust the roller distance according to customer needs to complete the production of different sizes.

Advantages of the angle steel frame making machine:

1. Greater practicality: Angle steel frame making machine can produce various sizes of templates. The angle of the angle steel needs to be determined in advance, typically 90 degrees, but customization is possible.

2. Easy operation: The customer can directly control the forming speed and cutting length via the PLC, and can also manually input orders to complete different batches.

3. More detailed: Our machine has an automatic oiler at the feed port to prevent the rollers from scratching the material and preventing dezincification during the forming process. A thermometer is also included on the hydraulic station, allowing workers to monitor the machine's operating status at all times.

Main parameter:

Part1. Manual Decoiler

Type: Passive opening coils

Coil width: Max 600 mm(As customers need to customized)

Loading capacity: 3 tons

Inner diameter: 450-550 mm

Our manual uncoiler is equipped with a brake device, which can be used for emergency braking if an emergency occurs during the uncoiler process.

Part2. Main forming machine

Feeding device:With 4 rollers.

Rolling shaft :

Shaft diameter:80 mm

Shaft material: 45# STEEL Tempering treatment

Rollers

Roller staions :11rows

Material: GB-Cr12

Tempered treatment (heat treatment) 56-58 degrees

Work speed:15 m/min

Machine frame:Vertical arch frame structure

Motor power:7.5 KW

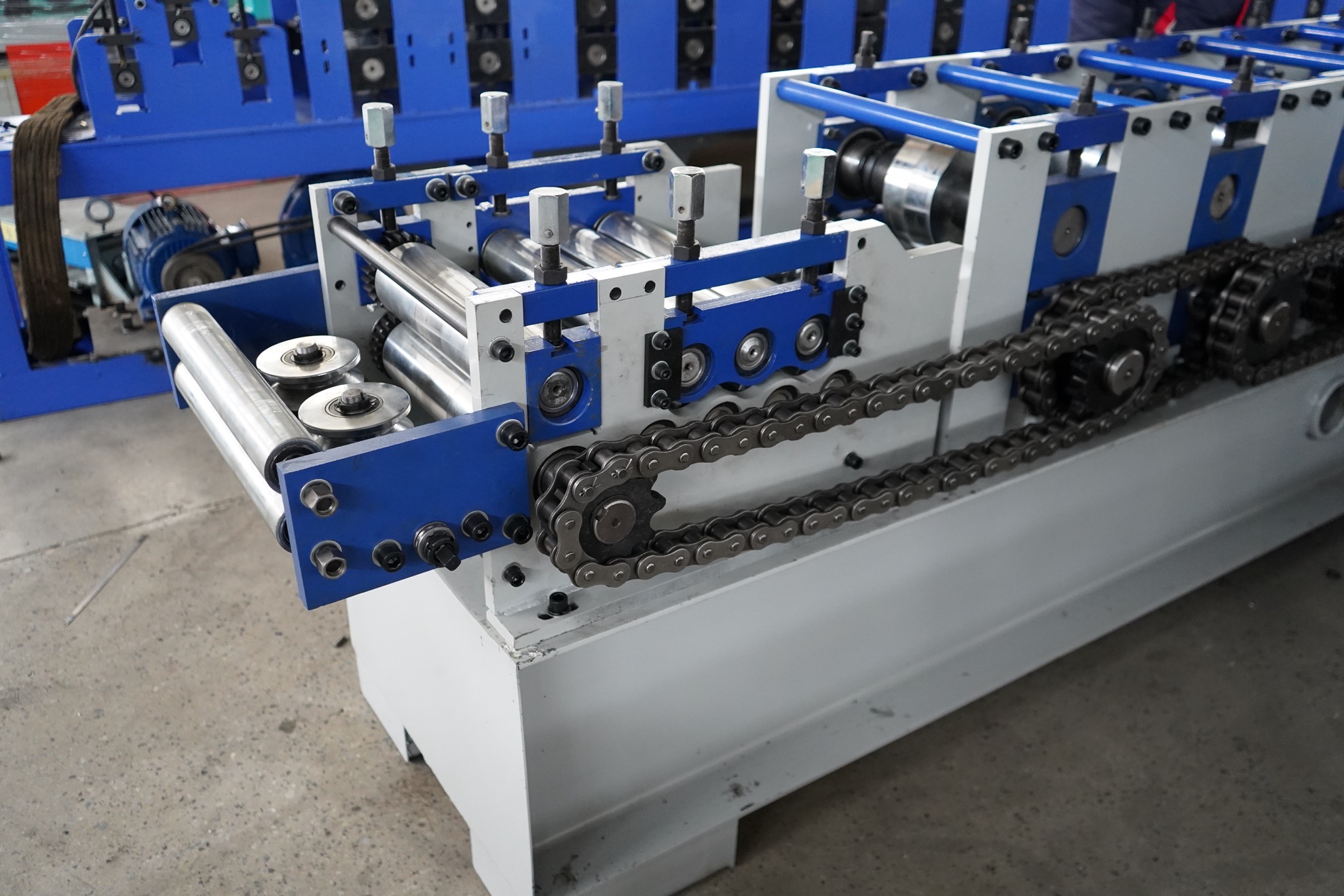

Transmission :By 1 inch chains(Double chains)

The main transmission structure of the machine is the middle shift chain, which adopts a 20mm thick middle plate structure. The chain is upgraded to a double chain structure to ensure more sufficient transmission force. We have also added a chain tensioning device to effectively adjust the chain tightness and enhance the service life of the machine.

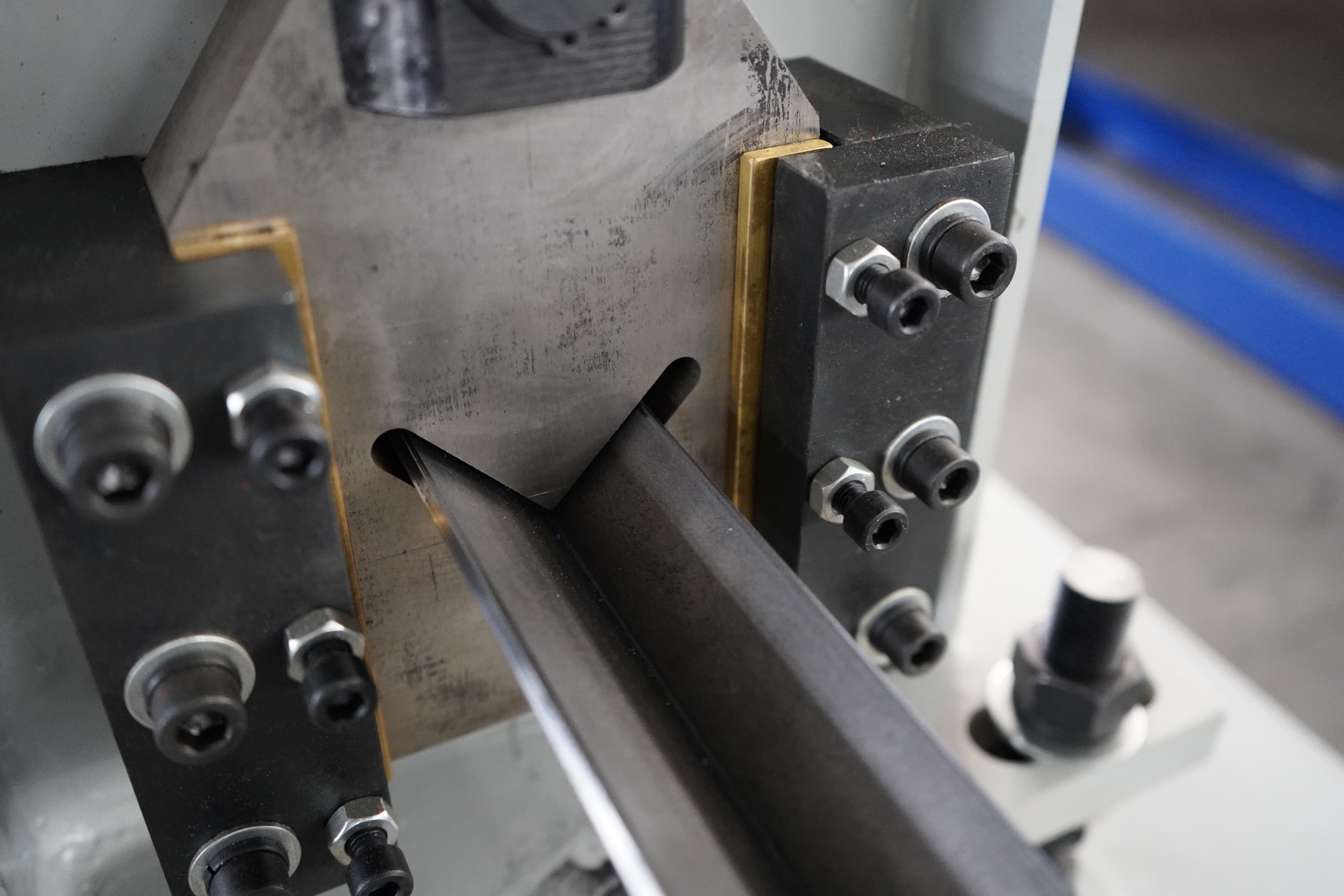

Part3. Cutting system

Cutting type:Stop cutting

Hydraulic motor power :5.5kw

Cutter material :GB-Cr12

Cutting length tolerance: ±1mm/3m

Oil tube and wires connection:

All the tubes and wires will be marked by the numbers or letters,so that it will be very easy to connect for the new.

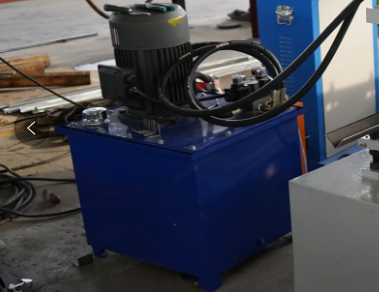

Part4.Hydraulic station

Part4.Hydraulic station

Hydraulic motor power: 5.5kw

Hydraulic oil:46#

Components:The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes.

Valves:They are all large valves, and the meters are also high-quality meters, which are more durable.

Hydraulic station with air conditioner

Cooling system: Dual fan cooling system inside the machine box

Part 5. PLC control system

Our PLC control system utilizes imported Delta/Siemens electronics, and our counters utilize Omron. The user interface utilizes a combination of touchscreen and physical buttons for dual-security control.

Our technicians will digitally mark the internal wiring diagrams before shipment to facilitate wiring. We also use aviation plugs for a more durable and secure connection.

Why choose Zhongtuo Machine:

Cangzhou Zhongtuo Roll forming machinery Co.ltd s a professional manufacturer of large and medium-sized machinery and equipment. Our factory has 16 yeas history, specialized in roll forming lines and roll former. There are about 100 staff working in our factory.

Professional sales team,experienced technical engineers and skilled production mechanics are the greatest factor in our success. Mr Cary Xu, the founder of the factory, is a professional sales engineer, who has been engaged in the design and manufacture of cold forming machines since 2006. Our machines exported to over 150 countires, achieving good fame.

We have 12 years of experience in machine exporting on Alibaba and are currently the number one factory in China for cold-bending machine export. We are a physical factory specializing in R&D, production, manufacturing and export. We have a full set of quality monitoring systems, customer reception service systems, quality inspection systems, and overseas after-sales service systems. We are a strong and reliable machine exporter. So far, we have signed a Sino-Korean joint venture with South Korea and a cooperation plan with Siemens Electronic Control in China. Our strong strength and sincere service are the basis for more than 150 countries around the world to cooperate with us.

One year’s warranty upon machine installed at the buyer’s site. The components are free replaced by new ones if non-human damage, Non-expense and on time technic support during machine’s whole life.

We have a professional technician team on call 7*24 hrs. to help the buyer solve any problems So that guarantee the machine works smoothly without break.