In the field of modern industry and construction, C Frame making machine has become the preferred material for many engineering projects due to its excellent performance and wide applicability. From the construction of building structures to the manufacturing of mechanical components, C Purlin making machine provides a solid guarantee for the efficient promotion and safe operation of various projects with its unique advantages. C Purlin machine can be used on roofs or roof supports, other supports in factories built with steel structures.The material thickness of C Frame making machineis about 1.5-4mm, width is 50-400mm, and the heights of both sides are 30-100mm.

A big advantage of C Purlin making machine is its high customization ability. Producers can flexibly change its size, specification and thickness based on different project needs. Whether large industrial factories need big-span and strong C Purlin machine or small civilian buildings requireC Frame making machine in specific sizes, these can be satisfied. Also, C steel can have surface treatments like galvanizing or painting as needed. This helps with anti-corrosion and appearance in different places, and extends where it can be used.

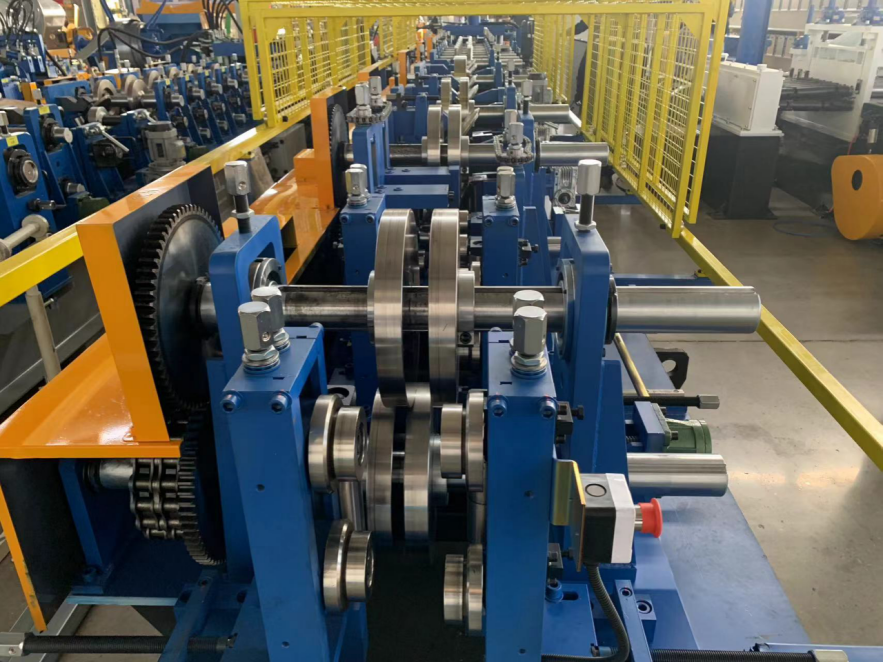

When mechanical transmission is needed, C Purlin making machine is mainly used with chain drive or gear drive.

First, let's talk about chain drive. It uses a chain to connect two wheels. When the wheels rotate, the chain moves along, transmitting power through the chain. This transmission has many advantages: it accurately transfers force, can drive heavy loads, and requires little effort, especially suitable for cases where two wheels are far apart. At this time, C Purlin machine firmly supports the chain. If it's not strong, the chain is easy to loosen or fall off, making the production line unable to work normally. For example, in the assembly lines transporting goods in factories, the C Frame making machinestructure ensures the chain runs stably and keeps production uninterrupted.

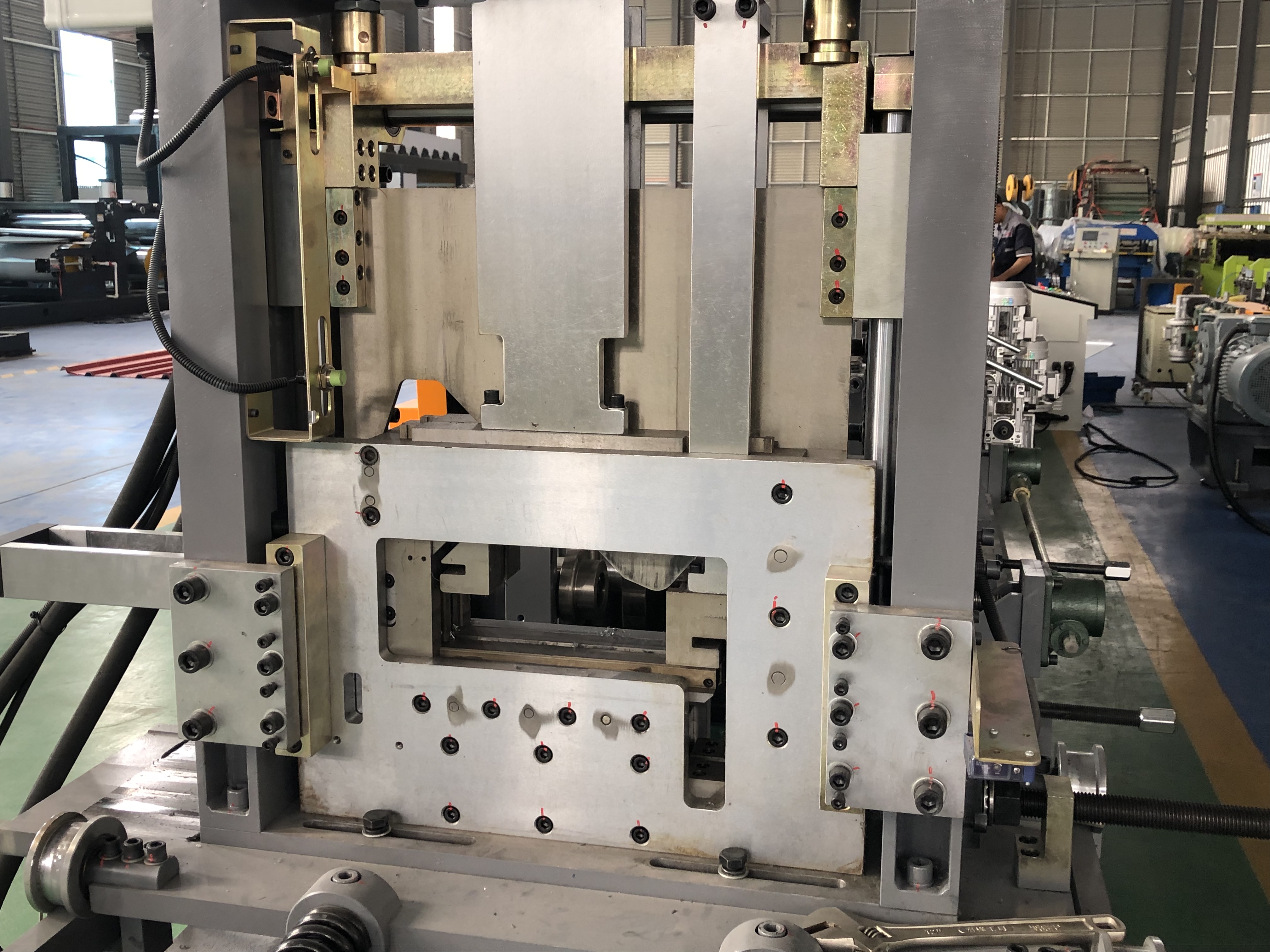

Next is gear drive, where two toothed wheels mesh with each other. When one wheel rotates, the other follows to transmit power. Gear drive is durable, space-saving, and reliable, often seen in places requiring high precision. When C Purlin making machine works with gears, it firmly withstands the thrusts and pulls generated by gear rotation. Without strong C Purlin machine, gears may wobble during operation, causing equipment failures and reducing precision.

In short, whether in chain drive or gear drive, C Frame making machine provides reliable support for mechanical operation with its strong and stable characteristics, playing a vital role in various mechanical applications.

In the production and use of C Purlin making machine , leveling is an extremely important process. The seemingly simple leveling operation can greatly enhance the quality and practicality ofC Purlin machine. During production and transportation, C Frame making machine is prone to surface unevenness and bending deformation, looking "crooked", which is not only unsightly but also makes people worry about its quality. After leveling treatment, the surface of C Purlin making machine becomes flat and smooth, and the lines are straight and smooth, greatly improving the overall appearance. The leveledC Purlin machinecan make the entire project look more beautiful and professional, enhancing the overall image of the project.

Unleveled C Purlin machinesteel has uneven force distribution, and its bearing capacity will be greatly reduced. Leveling can make its structure more stable. In this way, when subjected to pressure and tension, it is not easy to deform or break. In mechanical manufacturing, the leveled C Frame making machine, as the equipment framework, can better withstand the vibration and force generated during the operation of the machine, ensuring the safe operation of the equipment, extending the service life, and

making people use it more assured.

If the C Purlin making machine steel is unleveled, workers need to spend a lot of time and energy adjusting and correcting to fix the C Frame making machine in place, which not only has low installation efficiency but also is prone to errors. The leveled C Purlin machine. steel has more accurate dimensions and closer cooperation between various components. During installation, it can be quickly aligned and spliced, greatly shortening the installation time and reducing the labor cost. At the same time, the precise installation also improves the quality of the project and reduces the probability of subsequent maintenance and rectification.

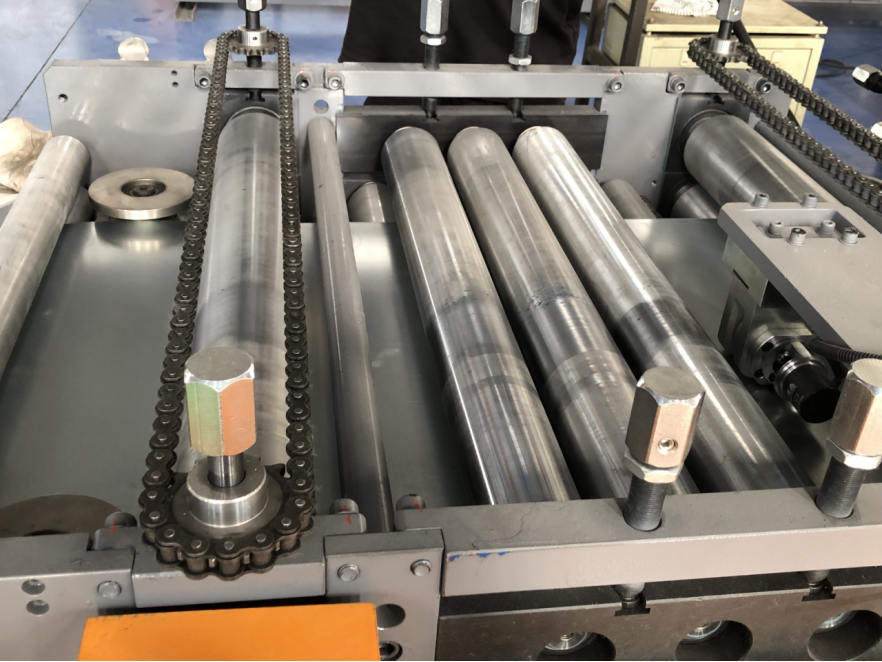

In the manufacturing process of C Purlin making machine, rollers are key processing tools. When the steel coil enters the C Frame making machineforming machine, a series of rollers start to work in sequence. Through the design of different shapes and positions, they gradually press the flat steel coil into a C shape. Each roller has its own "task" – some are responsible for initial bending, and others carry out fine adjustments, eventually shaping the steel plate into C Purlin machine that meets the specifications.

The precision of rollers is particularly important. If the rollers are not accurate, the dimensions of the pressed C Frame making machine will deviate, making it unusable. Through the precise operation of rollers, not only can the shape standard of C Purlin machine be ensured, but also the production speed can be increased, improving the production efficiency of the factory.