C Purlin Roll Forming Machine

What is Purlins?

Purlins carry the roof deck or sheathing loads and are supported by large rafters and/or building walls, steel beams, etc. In comparison to closely spaced rafters, the use of purlins is common in pre-engineered metal construction systems and both the ancient post-and-beam and newer pole construction methodologies for frame construction.

Purlins pass roof loads to the major structural elements supporting the roof; the form and arrangement of purlins is a design factor that depends on the instance of roof loads as well as the limiting sheeting lengths to use. In the final analysis, local building codes should always be understood and implemented in the design of a concrete roof structure.

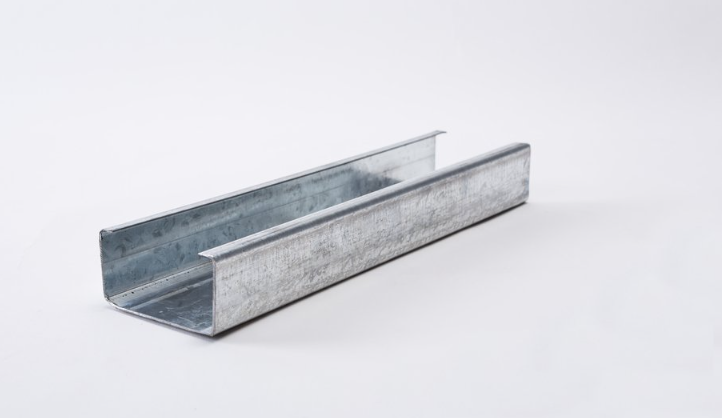

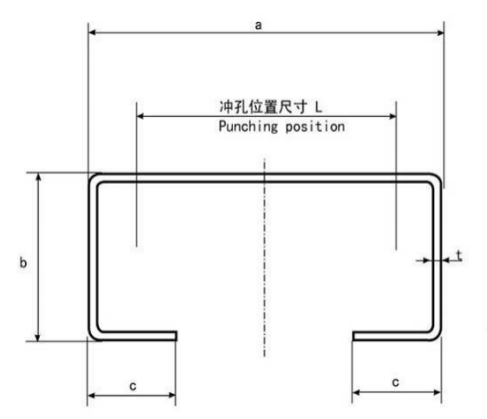

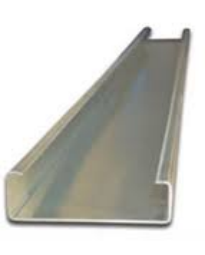

Basicl C section purlins are available in a wide range of thicknesses and are manufactured to the exact specifications of the customer up to any length, enabling them to be easily modified for use in buildings of various sizes. Bansal also manufactures them un-drilled or with different diameter pre-drilled holes (Oval shape and round shape holes of any dimensions can be provided on request). Web height up to 300 mm is available and thickness up to 3.2 mm is available.

Standard of C Purlin

Main Product

The Standard - CZ purlin machine has a specification of 13 m x 1.5 m x 1.7 m and weighs about 13 - 14 tons. Its total power is 32.5 KW. The CZ transform adjustment is manual, while the purlin size adjustment is semi - automatic. It features an arc frame and chain - driven transmission, with a speed of 20m/min. It is equipped with 5 pre - punching units, and both the decoiler and the receiving part are manual. The price of this machine is USD 45000.

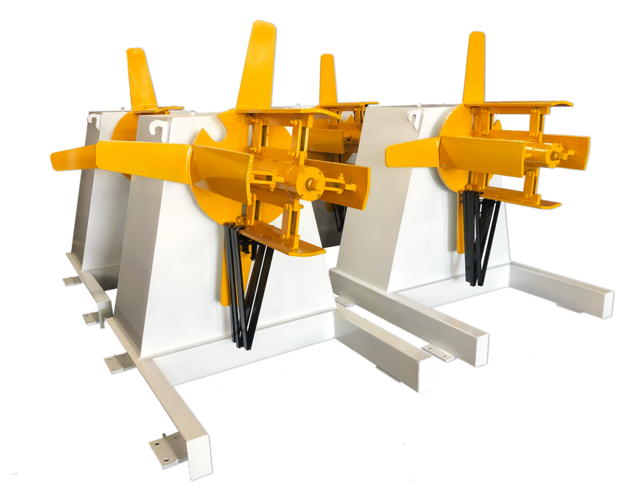

The 3 - ton Manual Decoiler is of a passive work type. It has a load capacity of 3 tons. The inner diameter of the coil it can handle ranges from Φ450 - 550mm, the outer diameter of the coil should be ≤1500mm, and the width of the coil should be ≤500 mm. The tightening method of this decoiler is manual.

Feeding and leveling

Main forming part

The main machine has the following parameters. It is equipped with 16 rows of roller stations. The roller shaft is 80 mm in diameter and made of 45# steel, while the roller shaft undergoes Cr15 quench treatment. The motor power is 15 KW. The table frame is composed of 400 U beam, and the transmission is achieved by chains. The machine structure features an arc frame, and its forming speed reaches 20m/min.

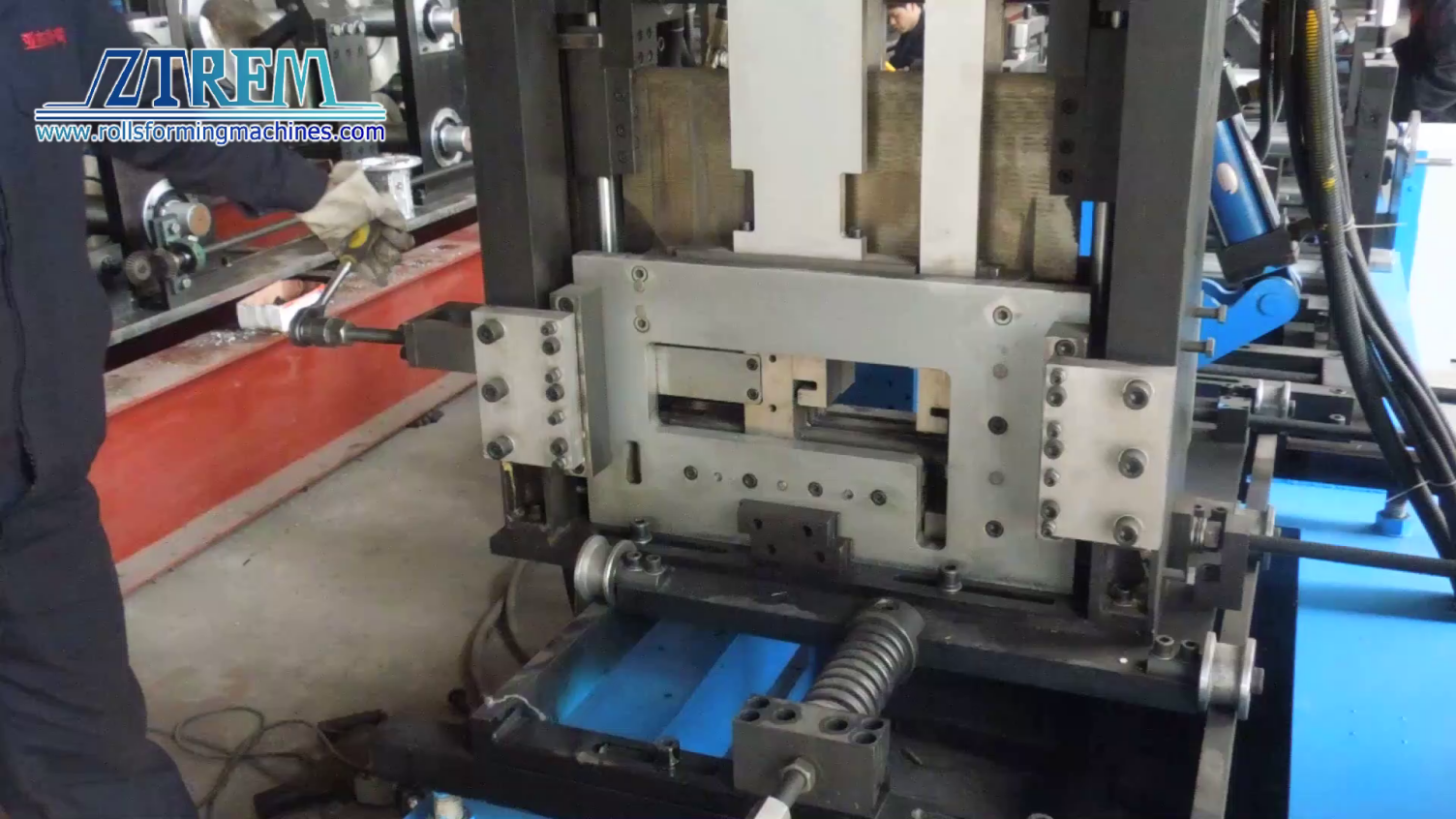

Cutting system

The hydraulic cutting system operates with a cutting type where it stops cutting after the forming process. It is powered by hydraulic power, with a power rating of 5.5 KW. The blade of the cutting system is made of Cr12mov material which has undergone quench treatment. The length measuring is done through an automatic encoder measuring method, and the tolerance of the length for a measurement of 3000mm is within + - 1.0mm.