1-3.5mm CZ purlin frame making machine

1-3.5mm CZ purlin frame making machine description

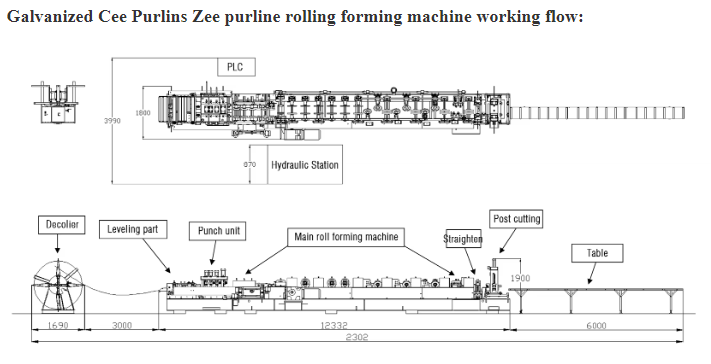

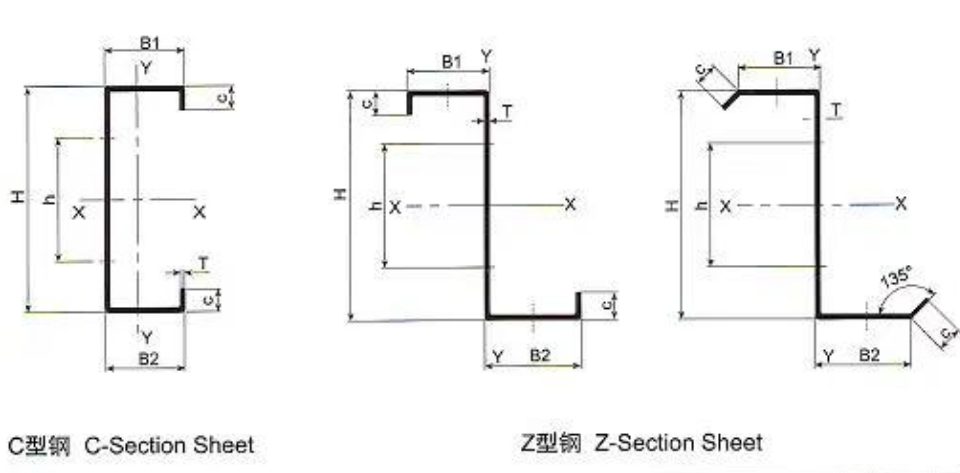

Zhongtuo 1-3.5mm CZ purlin frame making machine use high-speed gearbox transmission and support all sizes of C and Z models below. The machine can realize fully automatic size change and C and Z model conversion through PLC touch control.

Purlin machine parameter details:

C width 80~350 mm,

Z width (120~350mm) can be freely transformed;

Small edge (8-20mm) and small edge ≤ 0.8 * (waist height -20);

Waist height (30-100) mm and waist height ≤ 0.95 * (bottom width - small edge -30);

Adjustable plate thickness t (1.0~3.5) mm;

CZ purlin frame making machine supported material: Q195, Q235, Q345B hot-rolled strip steel or hot-rolled galvanized strip steel

Purlin making machine punching: It can support the following type punching,and also we can design machine according to your drawing profile

Because1-3.5mm CZ purlin frame making machine final material thickness we can process is 3.5mm, we designed the following machine configurations:

1. The feeding mechanism utilizes an integrated feeding and leveling design.

Feeding part: features a motorized feed roller and a feed roller wheel, adjustable to the width of the incoming steel coil.

Leveling part: Our leveling rollers feature a three-upper, four-down structure to ensure precise leveling. These rollers are made from solid wire, tempered, heat-treated, precision machined, and then electroplated. A servo motor controls the width and adjusts the leveling rollers.

2. Main forming machine: 23 roller rows (one of which is a waist-height-molded, 87-95 degree adjustable roller group).

4. Transmission structure: Independent gearbox type. A 1:1 gear ratio ensures efficient and stable production.

5. C and Z model changes: Equipped with 12 sets of CZ exchange modules, the switch can be completed by rotating 180 degrees, and the linear guide rail can be changed.

6. Added anti-concave roller device,

7. Added compression bar, straight bar, straight bar.

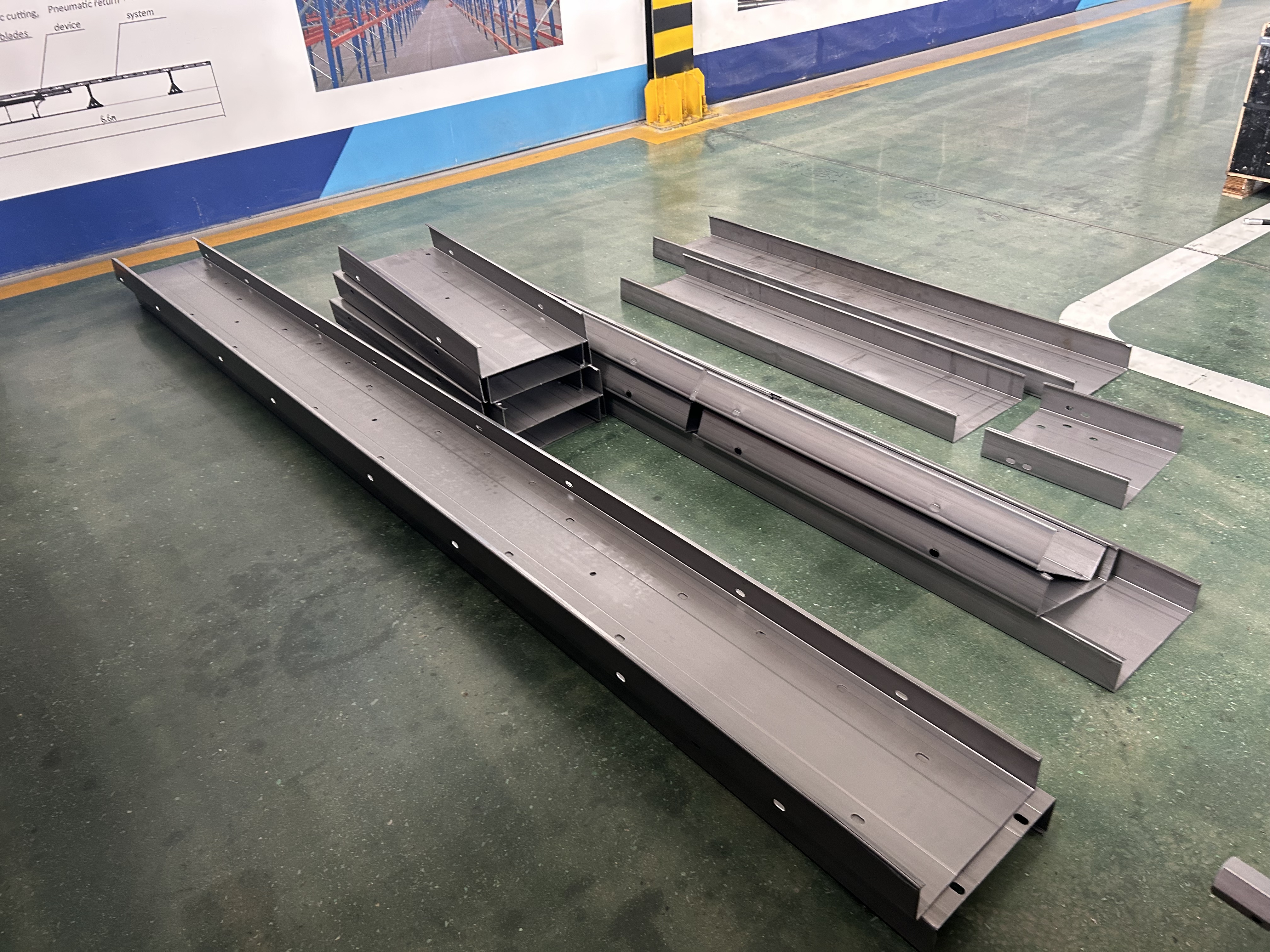

1-3.5mm CZ purlin frame making machine product display

5Tons Manual decoiler

Coil Inner Diameter: 450-550mm

Feed Width: Maximum 500mm

Structure: Manually operated coil expansion and contraction

Maximum Load Capacity: 8 tons

The manual uncoiler has a brake device to prevent material leakage and facilitate operation. It can also be equipped with a hydraulic uncoiler according to requirements. The hydraulic uncoiler is an active uncoiler with adjustable speed, which will increase the overall efficiency.

Feeding And Leveling Device

1.Has an electric button here, which can automatically adjust the feeding width

2.Leveling rollers: 3 up 4 down (Roller material:Cr15 Roller diameter: 75mm

3.Feeding width adjustment: automatic by button Make sure inputted steel sheet straight and neat and then roll forming process could be made accurate)

Puching Unit With Hydraulic System

Station 1: Pre-Hydraulic shearing

Station 2: Bottom center holes punching

Station 3: Bottom double side holes punching

Station 4: Each side flange holes punching

Gearbox Transportation

Servo motor drive, gear box transmission

The gear transmission ratio reaches 1:1, ensuring that the entire roller starts to transmit evenly when the machine starts.Ensure the high speed of the machine

Main roll forming machine

1. Rollers material:Cr12 CNC processing heat treatment to HRC: 58-60 ,finish turning Roller

2. Stations: 21 rows , 12 unit roller

stations for C and Z changing.

3. Shaft material:Shaft material: 40 Cr CNC processing HRC28-32 ,finish turning and electroplate Drive

Muti Sizes In One Full Automatic Adjustable Steel Frame Purlin Machines 1-3.5mm CZ purlin frame making machine

| ||

1.Formed Material | PPGI,GI,AI | Thickness:1.5-4mm |

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

3.Main | Roller station | 24 rows(As your requirement) |

Diameter of shaft | 90mm solid shaft | |

Roller Materials | Cr12 CNC machining, heat treatment to HRC: 58-60, precision turningMaterial of rollers | |

Machine body frame | Metal steel welded | |

Drive | Chain transmission | |

Dimension(L*W*H) | 12000*2500*1200(customize) | |

Weight | About 8T | |

4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

5.Power | Motor Power | 40KW |

Hydraulic system power | 15KW+cool system | |

6.Voltage | 380V 50Hz 3Phase | As your requirement |

7.Control system | Electric Box | Customized(famous brand) |

Language | English(Support multiple languages) | |

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

8.Forming Speed | 40m/min(customized) | The speed depends on the shape of the tile and the thickness of the material. |

Hydraulic Cutting system

1.Fully automated knuckle pressing

2. Fully automated cut of products

3.No need change cutter-produce different sizes C Z purlin in one machine

Our hydraulic station is equipped with a fan cooling system, and can also be equipped with an air conditioning cooling system according to production needs. The oil pump is equipped with a thermometer to monitor the temperature of the hydraulic oil at any time.

PLC control cabinet

1.Adopt Siemens electronic control, can support remote control

2.Adopt touch screen for easy operation.

3.Adopt aviation plugs for easy installation

4.Languages can be customized

The PLC control system supports the input of customers' fixed sizes and parameters. When using the machine, customers only need to select the size they want, which is easier to operate and saves time.

Automatic Stacker

Saving manpower

Can improve productivity

Equipped with rubber wheels and nylon pads to better protect the finished product.

Length: 6 meters The frame body is welded with channel steel and angle steel, and the roller is installed on the surface.

Related suggestion: If the local labor cost is high, you can also choose automatic palatalizing