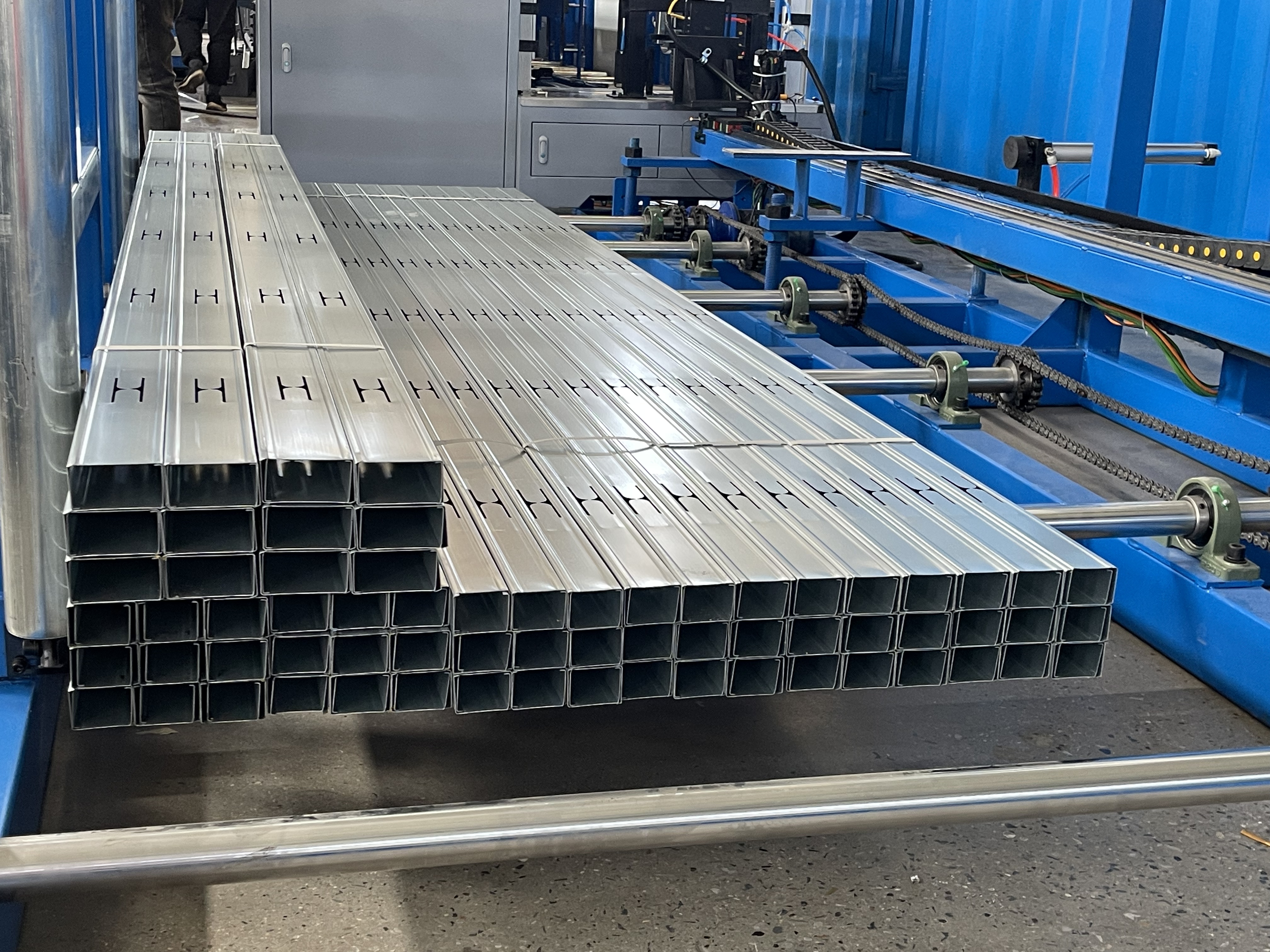

Fully Automatic & High Speed C Stud and U Track forming machine

Zhongtuo C stud and U track making machine version support customization. Production speed can be adjusted; the speed of our machine can reach 70m/min, equipped with a double head hydraulic unwinder and automatic palletizer. Our machines are equipped with a double-head hydraulic unwinder and automatic palletizer. The machines are of high production speed and reliable quality, and have passed the import certifications of ISO, CE, CSA, etc., which are worthy of your choice!

For the forming part of the machine, our inlet is equipped with an automatic oiler, which can inject wheel-slip oil into the raw material steel coil to prevent damage to the paint and zinc layer during the forming process; the machine inlet device is equipped with a handwheel, which can be easily adjusted! Our large frame increased diagonal braces to ensure the stability of the large frame. We use high-speed gearbox transmission, molding more stably, faster.

Feeding device: | With three rollers. |

Shaft diameter: | 70 mm |

Shaft material: | 45# STEEL Tempering treatment |

Rollers

| Rollers |

Roller staions :15 rows | |

Material: GB-Cr12 | |

Tempered treatment (heat treatment) 56-58 degrees | |

Max work speed | 70 m/min |

Machine frame | Vertical arch frame structure |

Motor power | 7.5 KW +11KW |

Motor power brand: | Customized |

Servo power | 1.5 KW*2 |

Details of the machine:

1. The language of the machine electronic control system supports customization. The width of the bottom edge of the machine can be adjusted fully automatically by PLC

5. The machine supports a customized punching device and an inkjet printer (finished product spraying the specified logo)