The hat-shaped structure of Furring frame making machine allows it to evenly distribute loads when stressed, enhancing its bending and torsional resistance, and making it suitable for supporting large-span buildings. It has a high degree of standardization, with different models flexibly adapting to various engineering scenarios. Produced by hot-rolling one-time forming technology, the process is standardized and precision-controllable, reducing material waste. During forming, multiple groups of forming wheels with different specifications are used to calibrate angles in sections, ensuring flat cross-sectional angles and small errors, providing a high-precision foundation for subsequent assembly and welding. It has a wide range of applications, playing a stable load-bearing role in building structures such as large-span factories and gymnasiums, as well as in rail transit support. With the advancement of prefabricated buildings and infrastructure projects, its characteristics of easy processing and convenient installation can greatly improve construction efficiency.

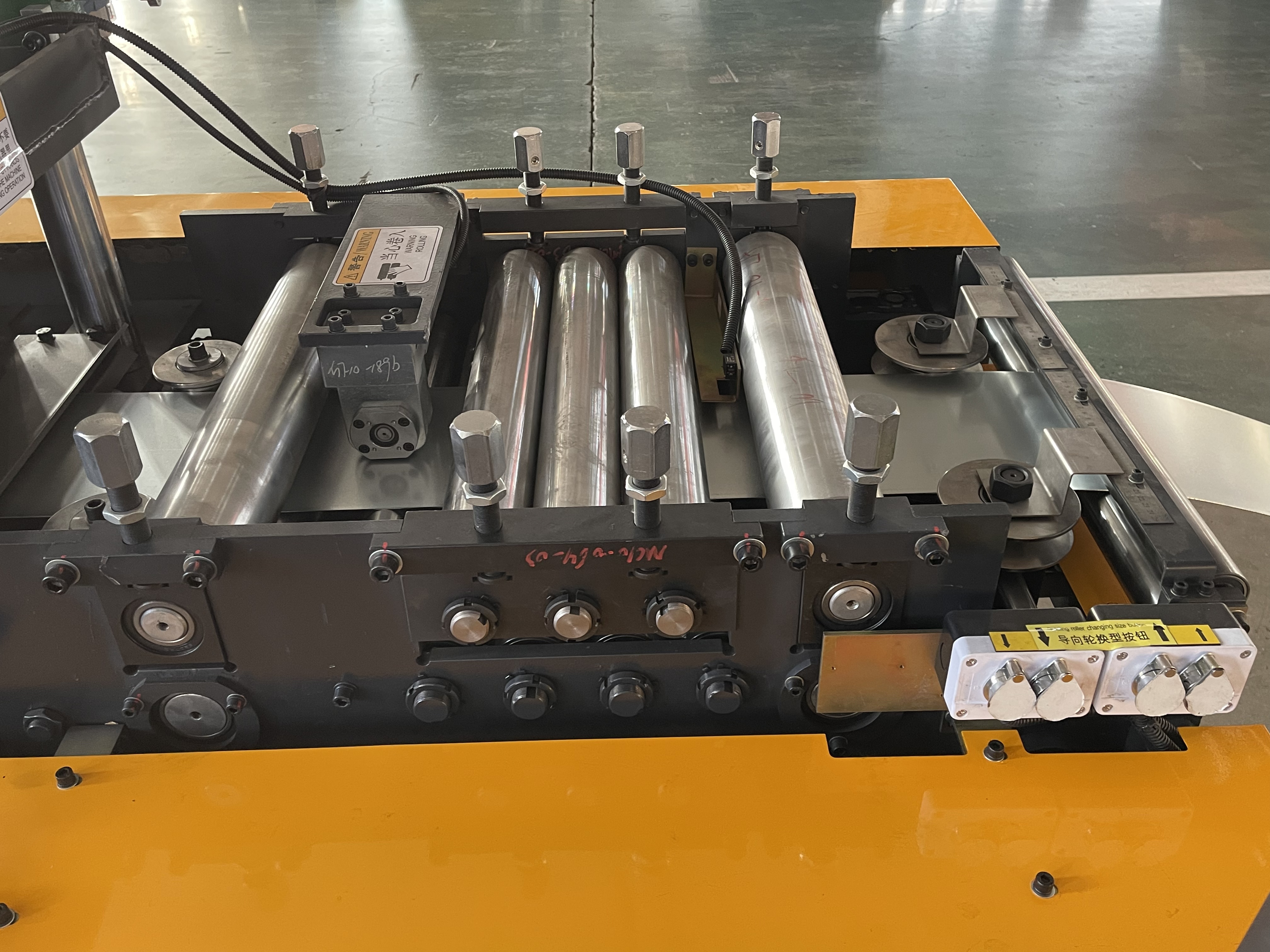

In the material forming of Furring frame making machine, to ensure the flatness and accuracy of the cross-sectional angles, multiple sets of forming wheels with different specifications are used for collaborative operation according to different forming stages and angle requirements. These forming wheels are professionally designed, and their contour shapes, diameter sizes, and surface precision are all optimized for the cross-sectional characteristics of Furring purlin machine.

Specifically, the forming wheel sets are usually arranged according to the principle of "segmented forming and gradual calibration":

Initial forming wheels: They mainly responsible for preliminarily rolling the steel into a basic profile close to the cap shape. The wheel surface is designed with a gradient arc, which can reduce material stress and initially fix the angle between the web and the flange at the same time

Angle calibration wheels: They are used for precise correction of the key angles ofFurring frame making machine, such as the vertical angles between the web and the straight leg, and between the straight leg and the flat leg. The edges of these forming wheels adopt high-precision grinding technology, with high surface hardness. By applying uniform pressure, the angle deviation can be controlled within a very small range.

Finishing forming wheels: As the last process, their wheel surfaces are mirror-treated, which can not only eliminate the fine wavy lines on the material surface but also perform secondary fine-tuning on the angles. Through the repeated rolling of multiple sets of finishing wheels, the cross-sectional angles of small Furring purlin machine reach the standards of flatness and smoothness, meeting the high-precision requirements of subsequent assembly or welding.

The material surface of smallFurring is flatter. Its cross-section is hat-shaped, with a regular overall contour and precise connecting angles at each part. The vertical deviation between the web and flange is extremely small, and the surface flatness far exceeds that of ordinary steel, with almost no wavy bending or local bulges. The finished product has high material strength and light weight, can evenly distribute loads, and has outstanding bending and torsion resistance. It can be directly used for building structures such as roof purlins of large-span factories and wall supports of gymnasiums, and is also suitable for structural support components in rail transit. Due to the adoption of standardized hot-rolling technology in the production process, the finished products have uniform specifications, smooth and flat surfaces, and can meet the requirements of subsequent processes such as welding and painting without additional grinding. When installed, it has a high degree of fit with other components, which can effectively improve construction efficiency. Especially in prefabricated buildings, it can be directly used as standardized components for rapid assembly, providing a guarantee for the stability and aesthetics of engineering structures.