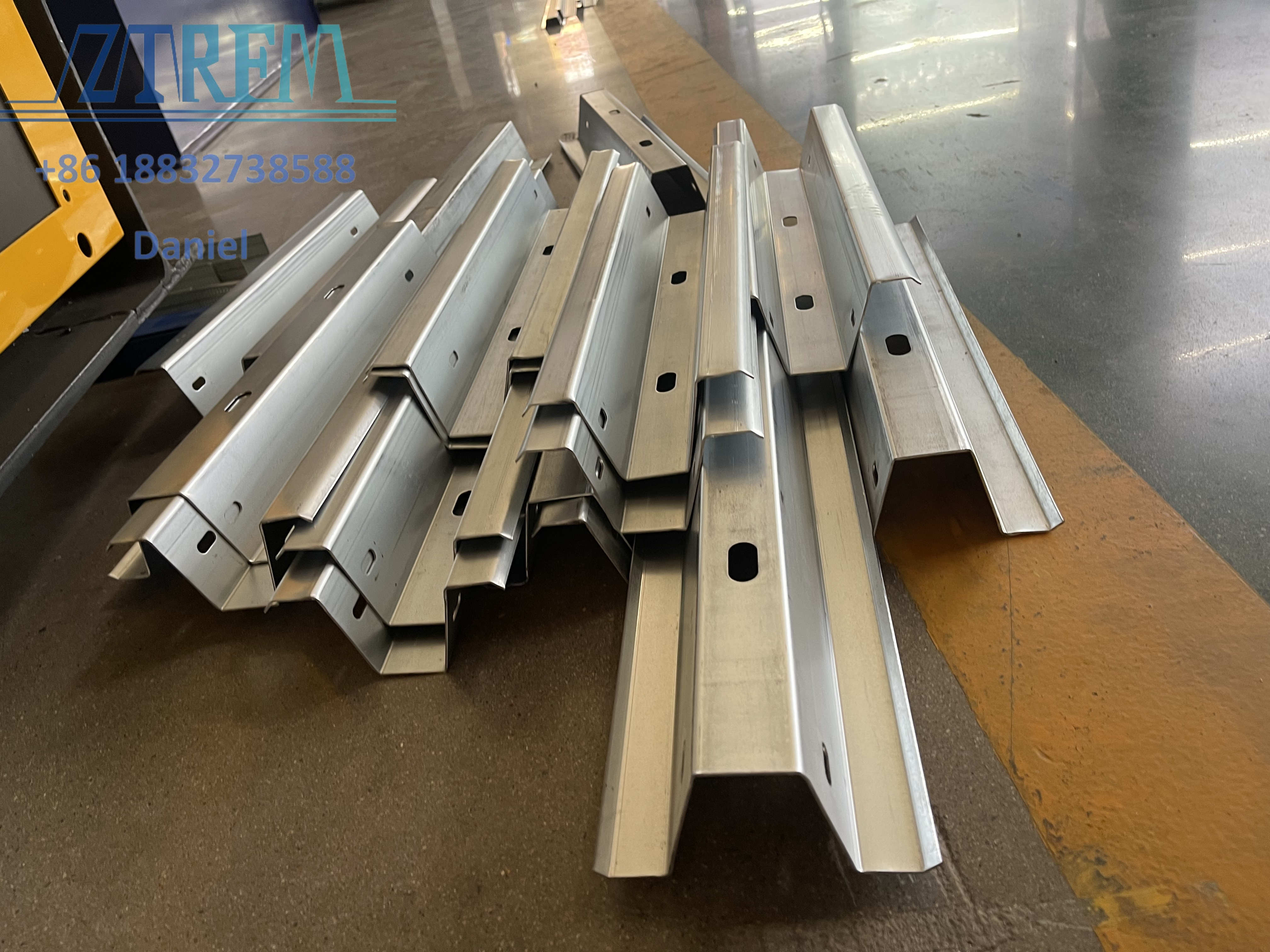

Hat Section Steel Purlin

Hat section steel, characterized by its distinctive cross-sectional shape resembling a hat, is primarily manufactured from 09CuPRE low-alloy high-strength weathering steel through hot-rolling processes. This specialized profile steel exhibits exceptional atmospheric corrosion resistance, high tensile strength, and superior weldability, making it indispensable in rail transport and structural engineering applications.

Key Applications

Railway Freight Cars

Used as side pillars in coal gondola cars due to its optimized load-bearing capacity and vibration resistance.

The 22-gauge model (with bottom width in centimeters) is standardized for Chinese rail vehicles.

Foundation Engineering

Combined with H-beams (e.g., 700×300×13×24) to form composite piles for soft-soil, enhancing lateral stiffness while reducing material usage.

Waterfront Structures

Serves as water-stop barriers insystems, demonstrating excellent sealing performance in hydraulic projects.

Technical Advantages

FeatureBenefitMaterial Properties≤0.12% carbon content ensures ductility and low-temperature impact toughness (-40°C)Structural Efficiency30-40% weight reduction compared to conventional I-beams, lowering transport/installation costsCorrosion Resistance09CuPRE alloy forms protective oxide layers, extending service life in humid environmentsModular DesignPre-fabricated welding joints enable rapid on-site assembly (45m/day progress achievable)

Comparative Analysis

vs. C-section Steel: Higher torsional rigidity due to closed-top geometry

vs. H-beams: Better localized stress distribution at connection points

Future Trends

Lightweight development (thinner webs/flanges) is prioritized to further reduce vehicle deadweight while maintaining structural integrity.