Light steel ceiling frame machine

U ceiling channel is often used in the construction of suspended ceilings of the roof frame overlap,

Our ZTRFM U ceiling channel machine, the degree of full-automatic, conventional speed of 40m/min and 70m/min two kinds of machines, the machine can through the PLC control system adjust the finished product length,molding speed, shearing speed.

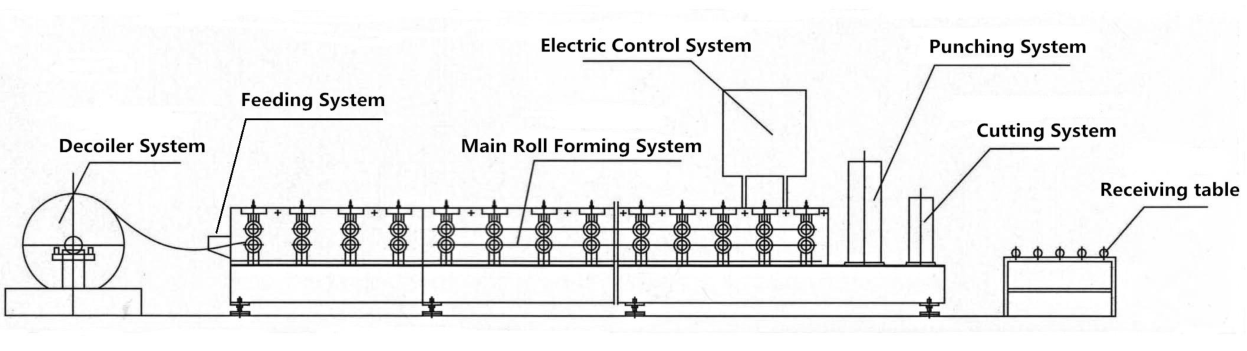

Working flow Chat:

Decoiler --- Feeding System --- Main Roll Forming System --- Electric Control System --- Punching System(Optional) --- Cutting System --- Receiving Table

Advantages

1.Automatic changing size type which is control by PLC

2.Flying shear with servo motor drived, speed can reach at 45m/min or faster as request

3.Equipped with automatic bundle machine

Mannal Decoiler

Type: passive

Coil width: max 400 mm

Loading capacity: 3 tons

Inner diameter: 450-550 mm

Feed Guide Device

A left and right guiding device at the main entrance of the machine. During work,Raw materials on both sides of the plate the enter into the machine by the left and right guiding device,make the raw materials and roll forming system to maintain the correct position. The guiding position can be adjusted by the manual screw mechanism,and the left and right can be adjusted independently.

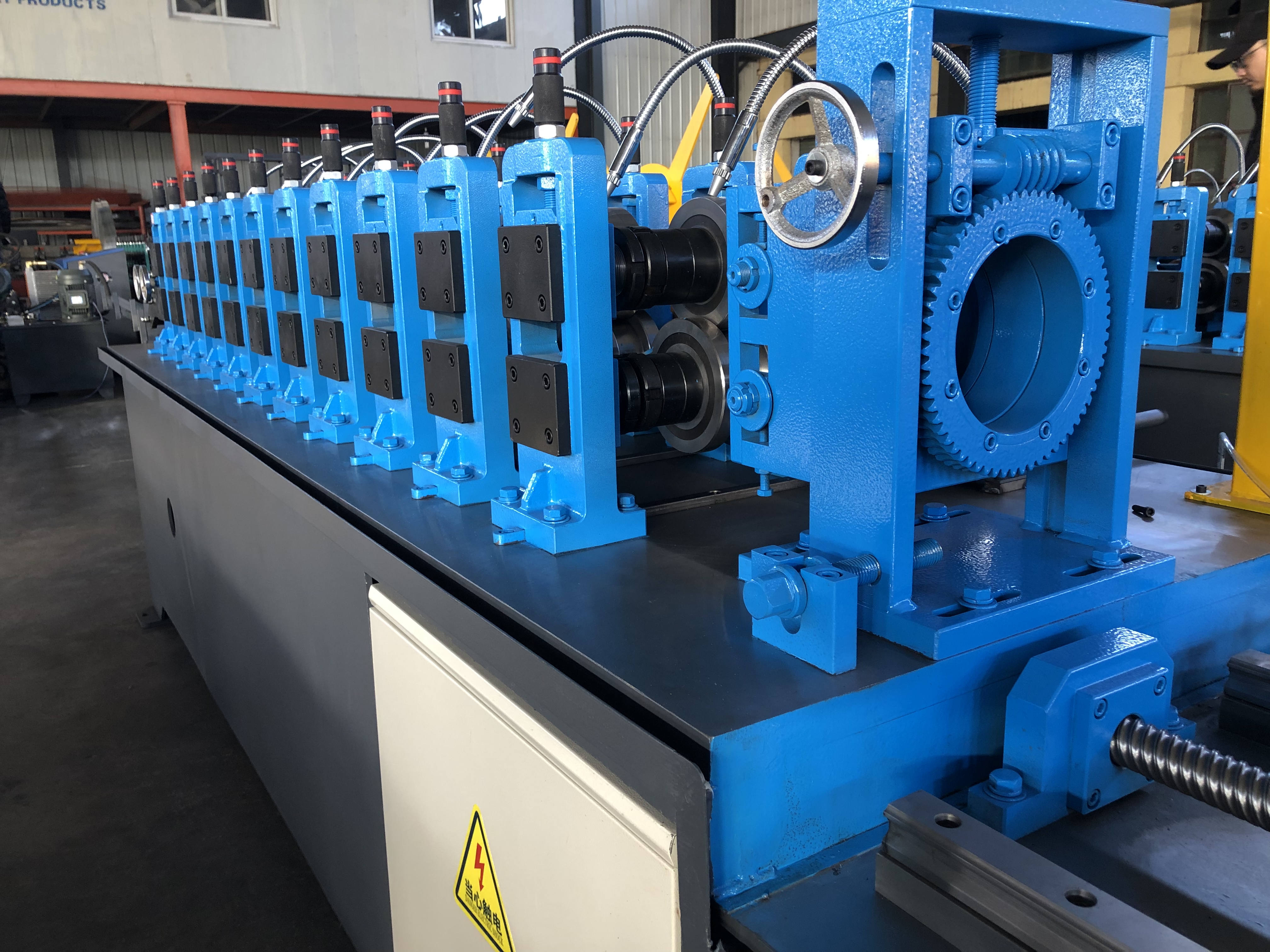

Main Machine

machine body frame: it adopts steel plate welding and CNC machining center processing

Rollers manufactured from Cr12MoV steel,vacuum quenching heat treatment after grinding the inner hole and end face, CNC lathe finishing roller face.

Shafts manufactured from 40Cr Steel,quenching and tempering heat treatment, hard chrome plating, and external grinding.Shafts

Diameter=ф55mm,precision machined

Gear/Sprocket driving,about 14-step to form

Main Motor(Polaroid brand)=15KW , Frequency speed control

Punching &Post Hydraulic Not Stop Cutting Device

No-stopping punching and cutting

Hydraulic servo motor:3 KW ;Cutting pressure: 0-14Mpa

Cutting tool material: Cr12MoV,(= SKD11 with at least one million times of cutting life),Heat treatment to HRC58-62 degree

The cutting power is provided by the main engine indepedent hydraulic station

Hydraulic Station

Hydraulic motor power : 5.5kw*2

Hydraulic oil:46#

Components:The system includes a set of hydraulic tank, a set of hydraulic oil pump, and two hydraulic pipes.

Valves:They are all large valves, and the meters are also high-quality meters, which are more durable.

Cooling system: Dual fan cooling system inside the machine box

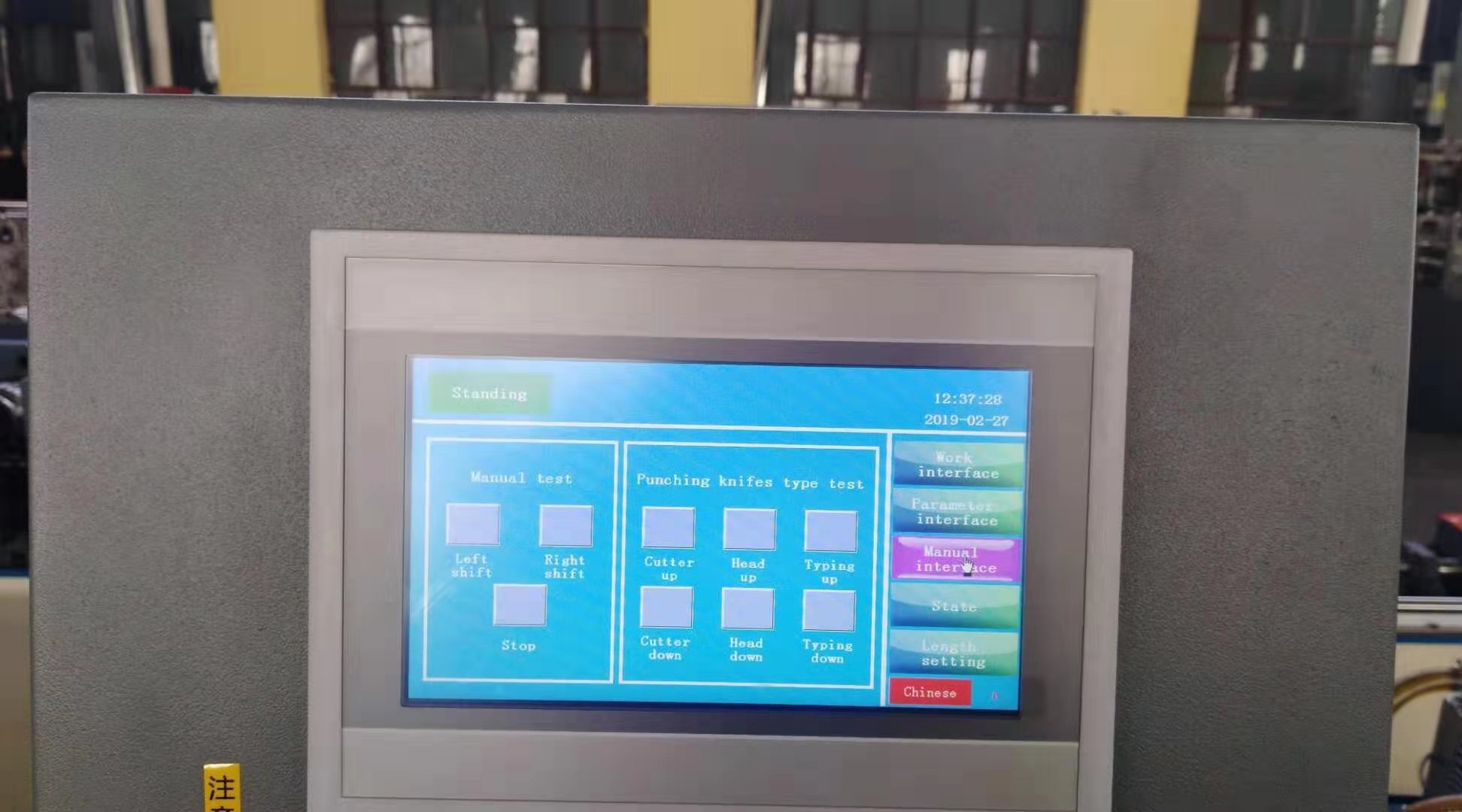

PLC brand: Delta

Frequency brand : Delta

Screen type: Delta

Encoder: Omron

Low Voltage electrical part:Schneider

Screen language : English and Chinese(add other language as client request)

Function : Control the cutting length and quantity, speed adjustment

Table length: 3000 mm

Table total width: 500 mm

Table material: square pipe welded