ZTRFM Fully automatic villa keel roll forming machine

Brief Introduction:

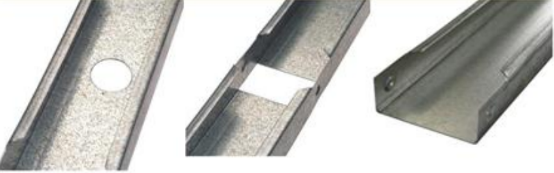

Fully automatic villa keel roll forming machine are becoming more and more popular in today's construction market. One Fully automatic villa keel roll forming machine can complete the entire structure of a two-layer or three-layer light steel villa. It is very suitable for the construction of tourist houses, hotels, and portable quick-build villas. It is becoming more and more popular in the United States, Australia, South America and other regions.

ZTRFM Fully automatic villa frame roll forming machine working flow chart:

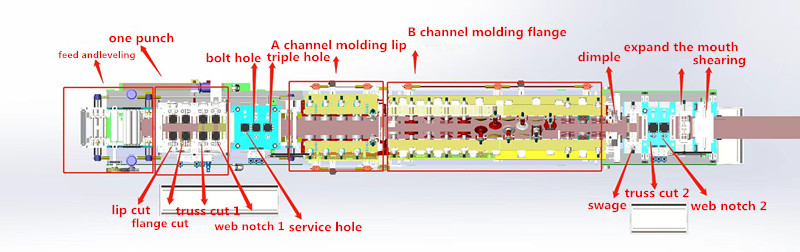

Our machine can produce coils with a thickness range: 0.5-2mm, customers' materials normally max is 1.5mm; the keel bottom width can adjust form 89mm to 350mm, our finish keel production support print logo and code(Traditional machines use inkjet printers, our machines have now been upgraded to use laser printers) . During the forming process, the machine needs to complete the punching and forming steps, end truss,swage,bolt hole,dimple,web notch,service hole,lip cut,flange cut,web hole in sequence.

Next, I will analyze and introduce our machine step by step through the following questions:

Q1. What parts does villa keel roll forming machine consist of?

| Part1 | Hydraulic decoiler |

| Part2 | Main villa keel forming machine |

| Part3 | Automatic production receive table |

| Part4 | PVC nylon wire baling machine |

Q2.What are the main parameters of the different parts?

Part 1.Hydraulic decoiler

Our hydraulic decoiler utilizes a simplified hydraulic cylinder, resulting in a compact design while maintaining stable speed and enabling faster expansion and contraction. We've also added a sensor to ensure optimal coordination between uncoil speed and the villa keel roll forming machine, ensuring worker safety.

Operating Mode: Hydraulic power station provides active uncoiler.

Working Width: Max. 500mm

Part 2. Main villa keel forming machine

A.Punchine die material (Raw materials use SKD11)

1.50X12mm side hole

2. Beehive holes

3.Function bolt for easy installation

4. 60x30mm for cable tray holes

5. 89x50 for the square holes

6. web hole and 45 degree bending or shearing.

Note: if your country bolt sizes are different, please tell me in advance.

B.Main rolling forming machine

1. Transmission, we use gear, chain as tranmission.

2. Main servo motor: 5.5kw

3. Roller material: SKD11

4. Shaft mateiral : 40Cr

5. Forming speed: 30m/min

Production capacity: 80 to 100 square meter per day, if you work 8 hours per day.

C.PLC control system

We are using the vertex system

Screen: Detla screen

Automatic length measurement

Automatic quantity measurement

PLC is used to control length and quantity. Machine will

automatically cut to length and stop when required quantity is achieved

Length inaccuracy can be amended easily

It is optical, you can choose others. Or if your villa sizes are fixed, you do not need to buy.

And if you feel manual inputting parameters is okay, and you also do not need to buy the software.

D.Printer equipment

What we are showing now is the inkjet printer equipped with our machine, but with the development needs, customers are more inclined to buy laser inkjet printers, which are faster and have more beautiful inkjet effects. We have two options

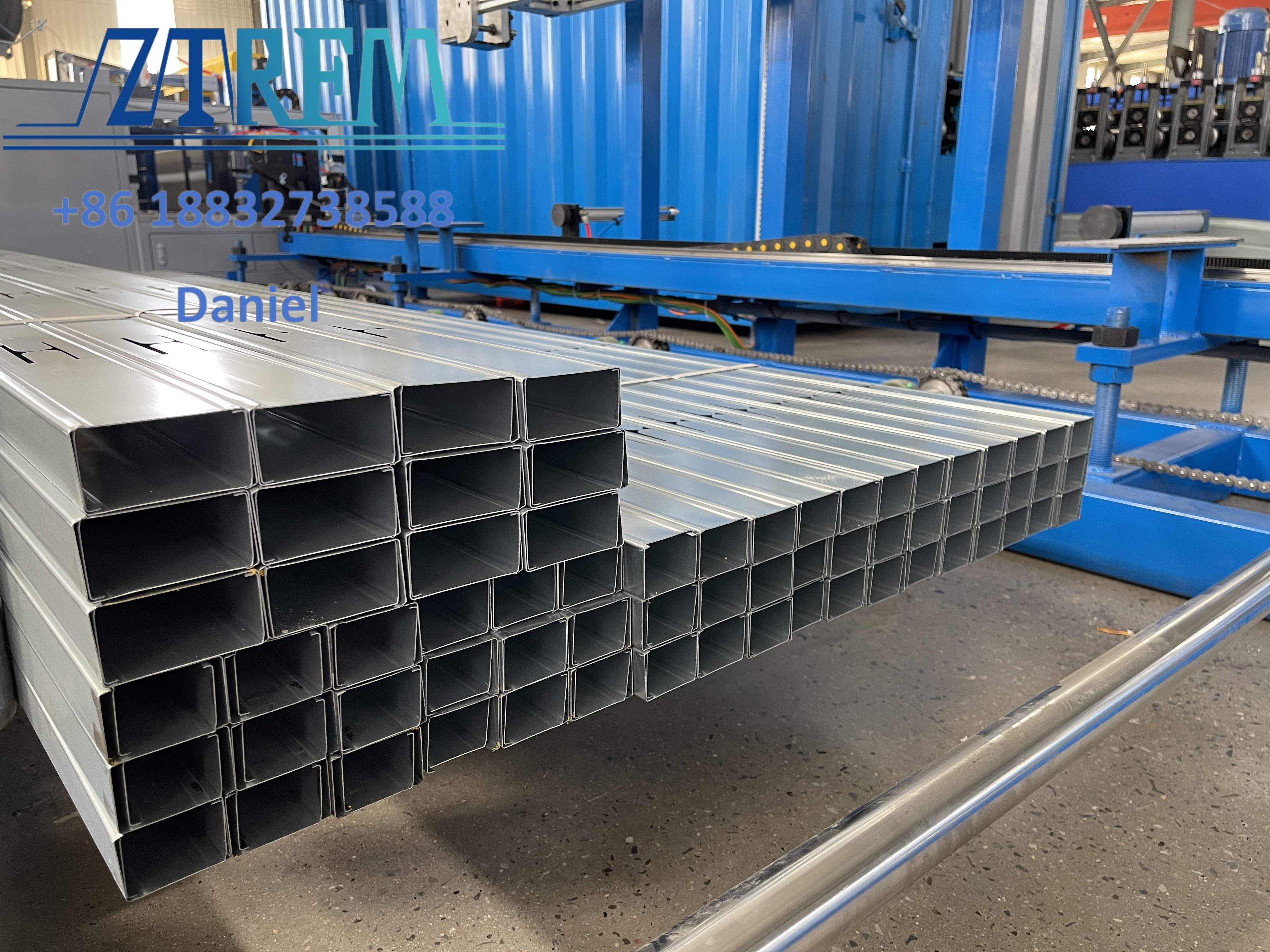

Part 3. Automatic production receive table

Because villa keel roll forming machine begins, the number of finished products is enormous,and the specifications vary.

Relying solely on workers to manually sort them would reduce efficiency and easily lead to mixing of finished products

of varying specifications.

Fully automatic material receiving racks, also known as automatic palletizers, use hydraulics to align,

push, and stack finished products. This is combined with an automatic palletizer.

Workers only need to use a forklift to remove the stacked finished products after switching models,

making this very convenient.

Q3. What are the advantages of ZTRFM fully automatic villa keel roll forming machine?

1. Highly automated, high production efficiency. Light steel villa light steel structure components are mechanized and can be fully automated in batches.

2. The machine's PLC system supports direct input of CAD or PDF drawings, making operation convenient for customers. Our operating system also supports remote control, facilitating both user experience and ongoing maintenance.

3. The machine is highly customizable, supporting width adjustment and a variety of interchangeable molds.

4. The machine features a dual control system, allowing for both automatic PLC adjustment and manual adjustment via electric buttons. This provides dual security. After automatic adjustment, manual adjustments can be made to minimize errors.

Q4. What are the detailed parameters of the machine?

PLC | PC control | |

Changeable distribution box | 1 (installed in the middle of the rack) | |

External controller | 1 (can facilitate the advancement and retreat in the production process and debugging process) | |

Main accessories origin | PLC (Panasonic, Japan), relay (Schneider, France), proximity switch (Ortonix, Korea) | |

Printer | One-piece inkjet (single nozzle, fixed side waist high spray) | |

power system | Servo motor 22KW+ curved bevel gear reducer | |

Mian hydraulic | Hydraulic station power 11KW + air cooling | |

Fuel tank capacity 200 liters | ||

Small hydraulic station | Hydraulic station power 3.75kw + heat sink; fuel tank volume 30 liters (underline flange mold) | |

Main parts origin | Solenoid valve oil research and development | |

Supporting weight: 5 Ton | ||

Expansion | Hand rail | |

The center of the four links is outwardly supported | ||

Driven | Motor drive, automatic discharge | |

Supporting length 12 meter, it has two parts, one is for 6 meter and another is for 3 meters | ||

Metahod | The frame body is welded with angle steel and angle steel, and the surface is loaded with rollers. | |

Roller | Material:Gcr12 | |

Processing technology: after CNC machining, heat treatment to HRC58-60, and then fine car | ||

Shaft | Material: 40Cr | |

Processing technology: after CNC machining, quenching and tempering treatment HRC28-32, and then fine plating | ||

Weight | The weight of the whole machine is about 9 tons. | |

Q5. Why choose us?

We are a one-stop supplier of cold roll forming equipment. We have 12 years of export experience on Alibaba and have a professional after-sales service team and overseas engineers. We are the manufacturer of the machine, so we understand the details that customers want better.