High Quality Triple Layer Forming Machine for three type tiles

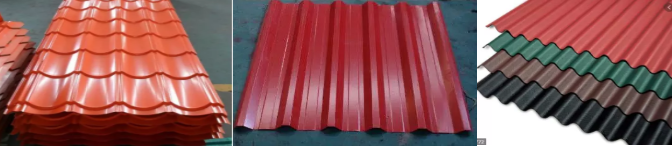

Glazed tile, Corrugated sheet and IBR sheet Three Layer Roofing Sheet Making Machine

The brief introduction of triple layer roof tile making machine

This machine can produce three kinds of roof sheet, glazed tile, trapezoid and corrugated roof sheet.

These three layers use one PLC control system, one hydraulic oil pump station, so each time only can produce one kind of profile.

Advantage of Three Layer Roofing Sheet Making Machine

Space-saving, cheap price

There are some picture of products for your reference.

Technical Parameter

Series | Details | Parameter | |

Product sheet | Raw material | GI&PPGI | |

Material thickness | 0.3-0.8 mm | ||

Feeding width | 1250 mm | ||

Sheet cutting length | Adjustable |

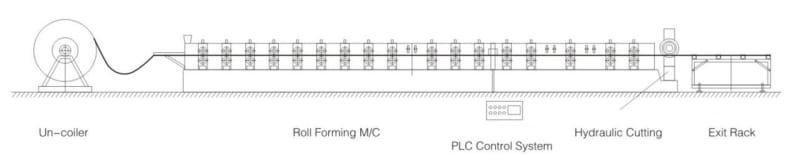

The work flow of roll forming machine

5T Manual Decoiler

Decoiler | Work type: passive type |

Structure: Steel channel welded for the basic frame | |

usage:To support the coil and make the uncoiling | |

Loading capacity: 5 tons | |

Inner diameter: 450-550mm (manual adjustment) | |

Coil width: 1250mm | |

Brake system: manual brake |

Main Roll Former

Roll forming macne |

Guide feeding device | Hand cutter |

Steel plate welded platform to carry the sheet and feed into roll forming system | ||

Feeding width is adjustable with the handle wheels | ||

Rolling shaft | Shaft material:High grade 45# STEEL | |

Shaft diameter: 80 mm, solid | ||

Tempering treatment to prevent deformed and improve hardness | ||

Roller | 45# steel | |

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

Rolling station | Glazed tile layer: 15 rolling stations | |

Corrugated layer: 18 rolling stations | ||

IBR layer: 18 rolling stations | ||

Work speed | 0-12 m/min (including shearing time) | |

Machine structure | Steel plate welded structure | |

Machine basic frame | 350# H steel welded | |

Work power | 5.5 kw | |

Rolling spacer | Anti rusty treatment | |

Pull rod | Anti rusty treatment | |

Transmission | By Chains with cover | |

Noted: please fill the lube in case the chains getting dry |

We could make such machine, but if not special sitation, we do suggest to use the double layer machine or single layer machine.