Double Layer Tile/Panel Roll Forming Machine

Double layer tile/panel roll forming machine can produce two different kinds of tile/panel with one machine,you can choose any two kinds of roofing tile/panel ,it can save a lot of room and money.metal roof tile/panel is widely used in constructions and buildings,it can be uesd to build roof and wall.This kind of material can be used in many places such as gyms,warehouses,factories,etc.

Here are some product pictures for your reference:

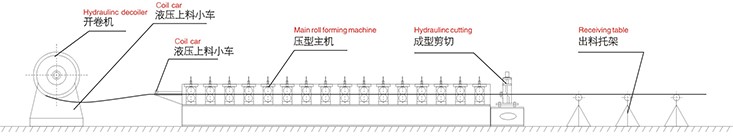

Work flow:Uncoiling→ Feeding material into machine →Roll forming → Auto shearing →Products receiving table

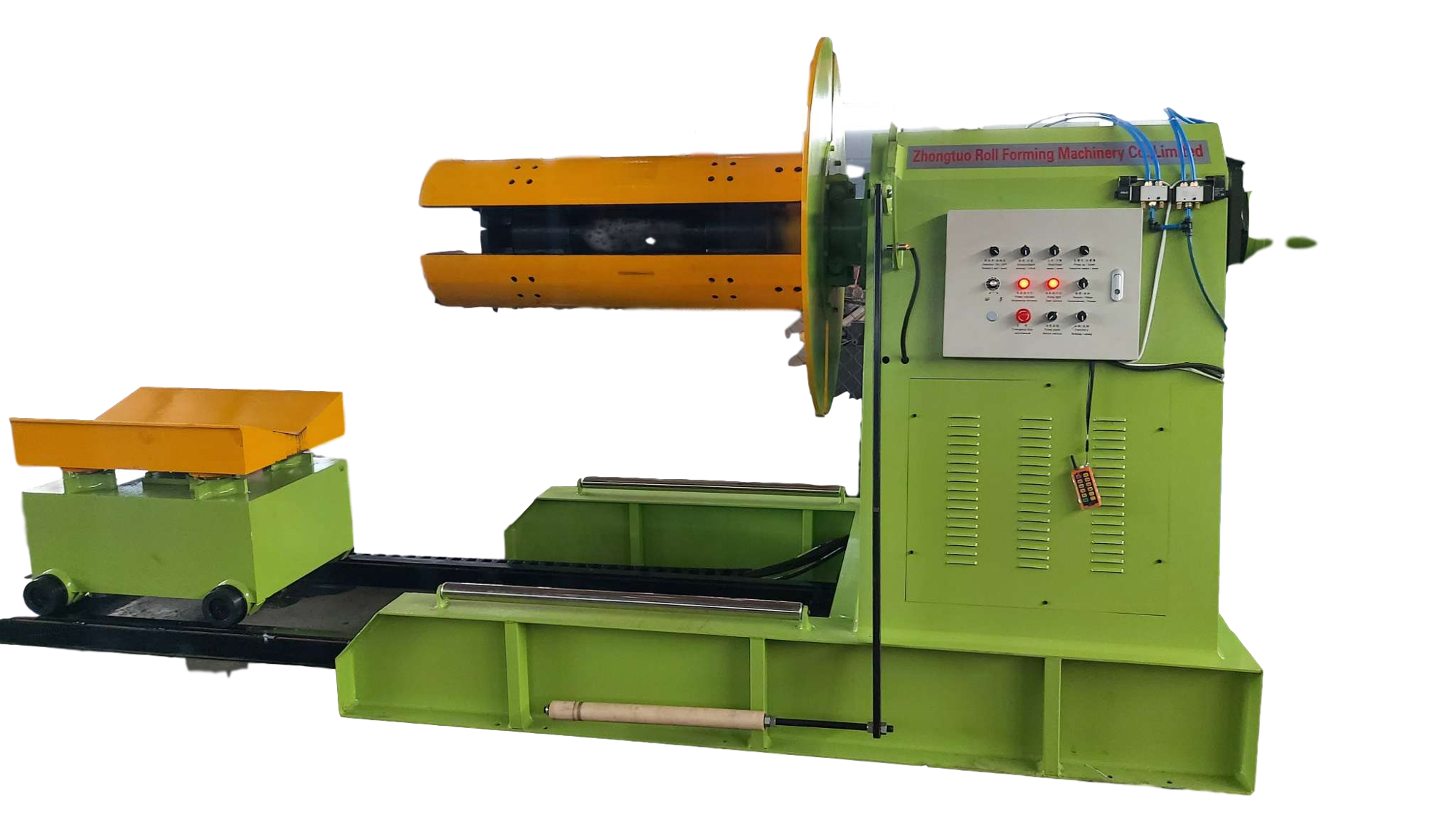

Hydraulic decoiler of Double layer tile/panel roll forming machine:

Loading capacity: 5 T ,6T or bigger

Uncoiling width: 1250 mm

Inner diameter: 450-550 mm

Double layer tile/panel roll forming machine: power:8.5KW

1.The plastic rubber roller at the feeding port can protect the paint surface from scratches and facilitate feeding.

2.External gears increase the transmission speed and ensure the stability of the equipment.

Why zhongtuo Double layer tile/panel roll forming machine is different:

1. Integral forming roll abrasive tools, chrome-plated surface. Increase the service life of the abrasive tool, the surface of the abrasive tool is smooth and will neither rust nor damage the surface of the paint layer, and is really durable.

2. Using Siemens motor, internationally famous brand, the quality is really good.

3.Gears are added inside part of the abrasive tools to ensure uniform force on the rolls,which can reduce wear, and shape beautifully and accurately

PLC system of Double layer tile/panel roll forming machine:

Hydraulic station of Double layer tile/panel roll forming machine:

It designs with the big motor.

With the hydraulic cooling fan system.

IBR/Corrugated tile/panel can be used in many scenes, here are some buildings that built with it ,which is really beautiful

Double Layer Tile/Panel Roll Forming Machine working video for your reference: