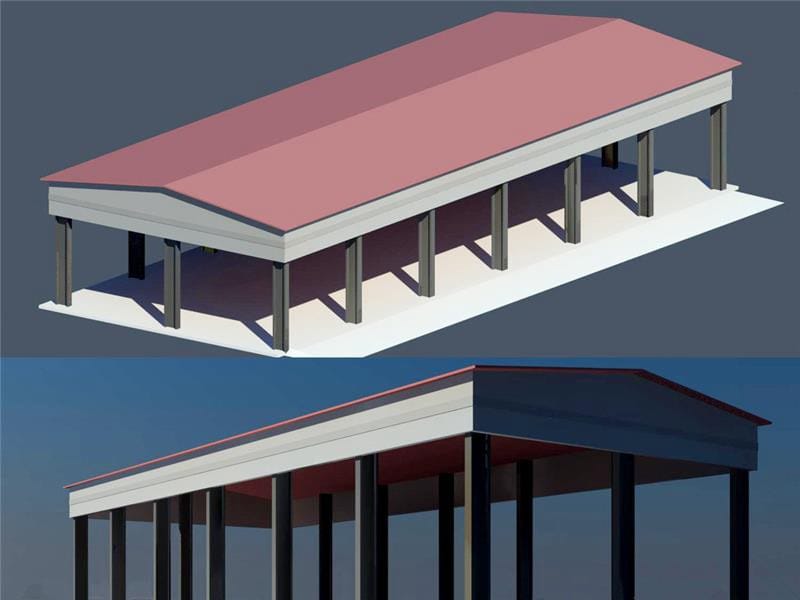

Indian Style Double Layer Roof Panel Roll Forming Machine

Product Description

What is the application of Indian style double layer roof panel roll forming machine?

Indian style double layer roof panel roll forming machine is mainly producing steel roof/ wall sheet .The final products have three types,corrugated sheet and trapezoidal sheet and glazed tiles.As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

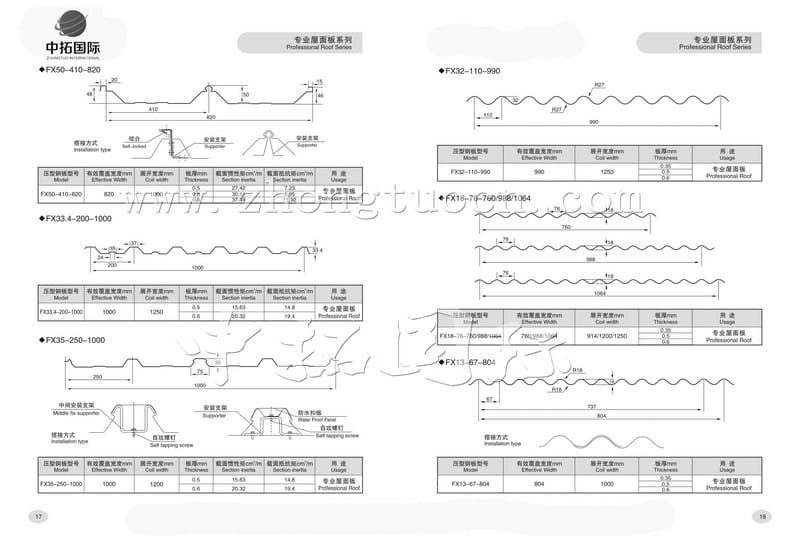

The specifications of the Indian style double layer roof panel roll forming machine1.Profile drawing(we can design as customer's profile drawing):

2.Components of the Indian style double layer roof panel roll forming machine

Item | Name | Remark |

1 | Manual decoiler | 5 tons/7 tons |

2 | Main roll forming machine | Famous brand motor |

3 | Control system | Delta / Siemens brand |

4 | Hydraulic system | Chinese famous brand |

5 | Receive table | 3 meters |

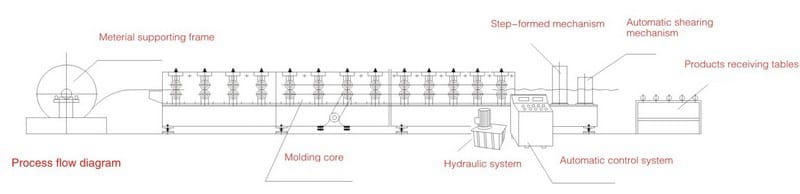

3.Process flow

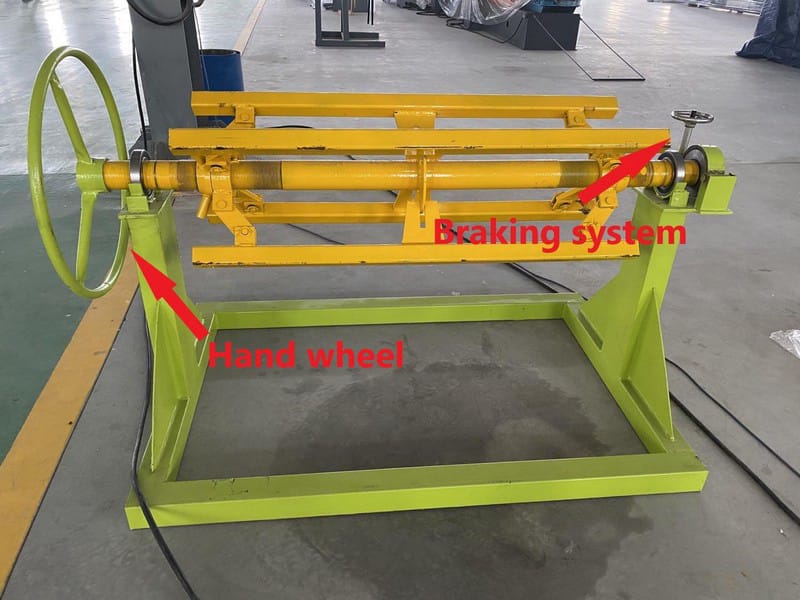

4.Manual decoiler (Hydraulic decoiler is also available)

Item | Name | Description |

1 | Capacity | 5 tons /7 tons |

2 | Coil diameter | 450-550mm |

3 | Coil outer diameter: | 1500mm |

4 | Coil width | 1200mm(as customers' profile drawing) |

5.Main roll forming machine

Item | Name | Description |

1 | Feeding device | With two hand wheels to adjust the feeding of the material,with bearing inside of the feeding rollers. |

2 | Machine body | 350H steel welded |

3 | Machine frame | Iron cast molding frame |

4 | Roller station | 18 stations &15 stations |

5 | Roller material | 45# steel with quenched treatment and hard chroming |

6 | Shaft diameter | 80mm,solid |

7 | Shaft material | 45# steel with tempering treatment |

8 | Motor power | 7.5 kw |

9 | Speed | 0-20m/min |

10 | Transmission | By double chain |

11 | Voltage | 380V,50HZ,3PH |

6.Cutting system

Item | Name | Description |

1 | Blade material | Cr12,with quenched treatment |

2 | Motor power | 4 kw |

3 | Cutting tolerance | +/-1 mm |

4 | Cooling system | With fan cooling |

5 | Cutting type | Hydraulic cutting |

6 | Feature | Low noise and high performance |

7.Control system

Item | Name | Description |

1 | Control system | PLC |

2 | PLC brand | Delta from Taiwan |

3 | Frequency converter brand | Delta from Taiwan |

4 | 5 Encoder | Omron |

5 | Function | Automatic control the length,quantity and batch |

Some pictures of machine for your reference

Manual decoiler

Roll forming machine

Double layer machine working videos for your reference: