What is the application of high speed roofing sheets machine?

Roofing sheets machine manufacturers is mainly producing steel roof/ wall sheet .The final products have teo types,corrugated sheet and trapezoidal sheet.As we know, steel roof/ wall sheet is widely used in large span factory building, warehouse, office buildings, villas, roof, cold storage, air purification room, stores, kiosks, and temporary housing.

What is the advantage of high speed roofing sheets machine?

1.The system is easy to operate and use. PLC: Delta(Can customize as customer require)

2.the surface of the final product is very smooth and beautiful without any scratch on the surface.

3.customized:design the machine according to your specification and profile drawing.

Fully Automatic High speed Roofing machine.

Machine base is available for Quick Change platform type, multi-profile purposes.

Production Speed: 25/ 50/ 75 M/min. Product Length: 2.0 ~ 12M.

Raw Material: Pre-Painted Steel sheet G300 ~ 550. Plate Thickness: 0.3 ~ 0.6mm.

Automatic motorized cutting machine.(no hydraulic / pneumatic required).

Automatic piling device. Quantity / Batch automatic production mode available. With unloading chain for reducing the suspension time of different orders.

Machine Progress:

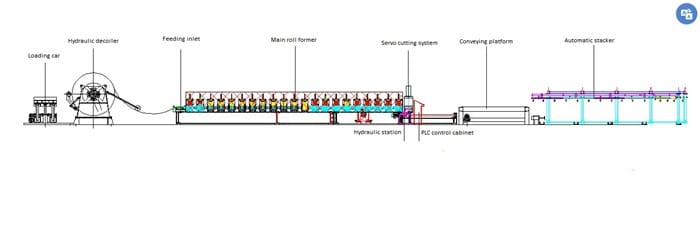

Decoiler → (Option: Pre Cut) → Rollforming → Motorized Cut-off → Conveyor → Double Sided Stacking device → Unloading Device

What is the specification of roofing sheets machine?

Roll forming machine | Feeding device | the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.` Meanwhile, protect the steel sheet surface without damage. |

| The feeding system length:750mm |

Rolling shaft | Shaft Material: 45# STEEL |

| Shaft diameter: 90 mm |

| Tampering treatment, prevent deformed and improve the hardness |

Roller | Roller material: 45# steel |

| Chromed treatment (Cr thickness:0.05 mm), anti-corrosion, Increase hardness, ensure the precision and good abrasion performance |

Rolling station | 22 stations |

Forming type | Separate rolling design concept |

Work speed | 0-35 m/min |

Machine structure | Vertical arch frame structure |

Machine basic frame | 500# H steel frame welded |

| The diagonal bracing will be welded inside the basic frame |

Bearing | Chinese famous brand Harbin |

Work power | 11 kw ( gear reducer and servo motor driving) |

Roller spacer treatment | Electroplate (chromed) |

Steel bar treatment | Electroplate (chromed) |

Transmission | Gear box, more powerful and steady |

Safety cover | The machine will stop directly when the cover open, and need restart the machine manually on the control station |

Details of high speed roofing sheets machine