Stone Coated Metal Roofing Tile Sand Coated Metal Roof Tile

Sand coated metal roof tile is a new type of advanced roofing material produced by high and new technology, which takes aluminum zinc coated steel plate with excellent anti-corrosion performance as the substrate, aqueous acrylate as the adhesive, sintered colored sand as the surface layer, and acrylic resin with strong weather resistance as the outermost layer (equivalent to paint). Because of its beauty, lightness, durability and environmental protection, it has become the mainstream product of international roofing materials in recent years, which is used in high-grade buildings.

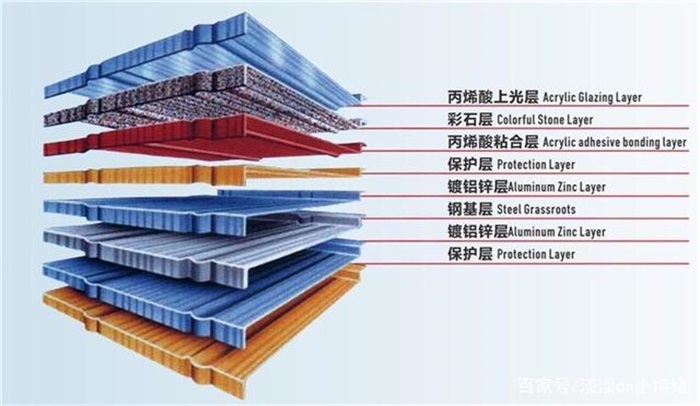

structure

It is composed of aluminium zinc coated steel plate as substrate, fingerprint resistant coating, color sand, acrylic resin and acrylate.

1) The aluminum zinc coated steel plate is formed by hot plating with a hot plating solution composed of 55% aluminum, 43.4% zinc and 1.6% silicon. Its processability and coating are basically the same as that of galvanized steel plate. The normal service life of aluminum zinc plated steel plate is 2-6 times that of ordinary galvanized steel plate.

2) The fingerprint resistant coating is on the top of the aluminium zinc coated layer. The fingerprint resistant coating plays a role in protecting the aluminium zinc coated layer. At the same time, the fingerprint resistant coating can better bond the aluminium zinc coated steel plate with the colored sand. The color of the fingerprint resistant coating is divided into colorless, transparent and light green.

3) Sintered colored sand is the decorative layer and base protective layer of metal tile. It is made of basalt particles with a certain particle size through high-tech coloring process and high-temperature sintering. With more than ten colors, it can resist ultraviolet radiation and reduce the noise caused by rainwater to metal tiles.

4) Acrylate is the key material for bonding steel plate and colored sand. At the same time, it is also used as the protective layer of sand mining surface to prevent the leakage of detail rainwater and prolong the service life of sand color.

5) Structure of stone coated metal roof tile

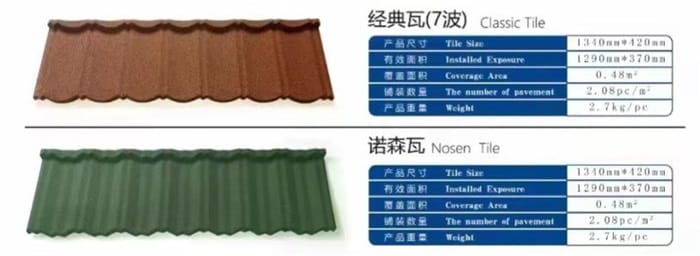

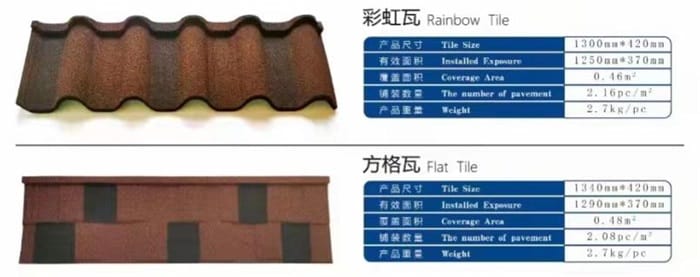

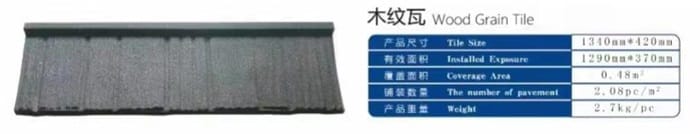

Common types of stone coated metal roof tiles:

Classic tile (7 waves), Nosen tile, Milan tile, Roman tile, rainbow tile, flat tile and wood grain tile.

Main features

Green, environment-friendly and beautiful appearance - stone coated metal roof tile, not falling, not afraid of sun exposure, bright color, not afraid of acid rain, sound insulation and noise reduction, self-cleaning surface and lifelong maintenance free

Strong weather resistance - after professional testing, the colored stone metal tile can maintain its good performance in the temperature range of - 40 ~ 100 ℃.

Earthquake resistance - when an earthquake occurs, the metal tiles will not slide like ordinary tiles to reduce injuries.

Light weight - light weight, reducing the load-bearing of buildings.

Construction convenience - light weight, large area, simple accessories, greatly reduce the construction intensity and shorten the construction time.

Economical - in the roof construction of old buildings, there is no need to remove any roof materials, and the construction can be carried out directly, so as to minimize the cost of waste disposal.

The color stone tile has weatherability, moisture resistance, salt spray resistance, impact resistance, acid resistance, alkali resistance, heat resistance and non combustibility. The product takes aluminum zinc plated steel plate as the base material and has multi-layer protective film treatment. It can withstand the attack of severe weather and natural disasters such as severe cold, hail, storm, rain and snow, extreme heat and earthquake. It will not crack, age, burn in case of fire and lift by wind. It has a long service life of up to 30 years.

Common specifications of stone coated metal roof tile

Take 0.4mm thick aluminum zinc plate as an example

Taking the classic tile (7 waves) as an example, its conventional specification is 1340 * 420 * 0.4mm, and 0.4mm is the thickness of metal tile steel plate. Two tiles can be laid flat, and the overlapping part is removed. The effective area is 1290 * 380mm, the coverage area of a single tile is 0.5m2, and the weight of a single tile is 2.7kg.

Sand coated metal roof tile is simple and convenient to install. It can be used for wooden roof frame, steel frame, all steel grid frame and concrete roof. Because it is easy to bend and cut, it is suitable for all kinds of buildings. It can also be safely constructed for roofs with a slope of (12-90 degrees), especially for "flat to slope and roof renovation" projects. At the same time, it can replace the original clay tile, cement tile, color steel plate, glass fiber asphalt tile, slate tile, etc. during construction, it is not necessary to dismantle the original roof, so it can be constructed directly. Due to the large surface area, light weight, bending and cutting of metal tiles, they are firmly connected and fixed by adopting unique buckle design and structure and horizontal nailing. This dry construction is simple, fast and saves materials.

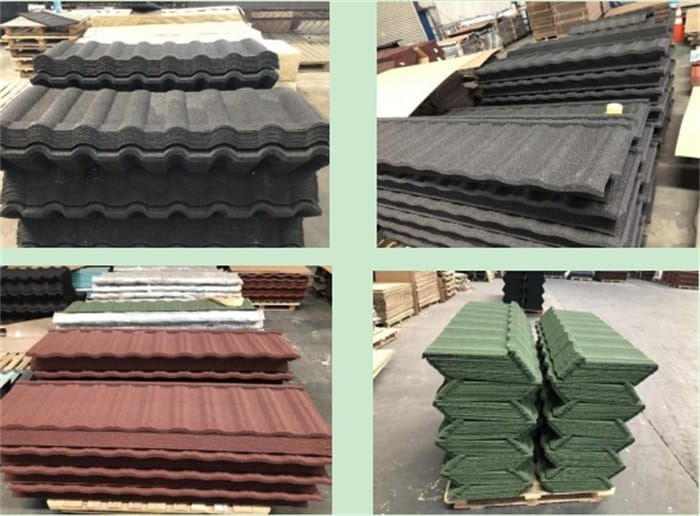

Stone coated meta roof tiles have various colors and can be customized according to your needs. The following is the reference color card.

Code | Color | Code | Color | Code | Color |

2218 | Brick-red | 4718 | Iron color | 23-1 | Agate red |

8318 | Grey | 4218 | Coffee color | 9318 | White |

7518 | Blue black | 8418 | Blue | 3718 | Green |

7918 | Dark grey | 5218 | Black | 4618 | Brown |

3752 | Green+black | 5693 | Tiger skin color | 5293 | Black+white |

2252 | Red+black | 5284 | Black+blue | 4246 | Coffee+brown |

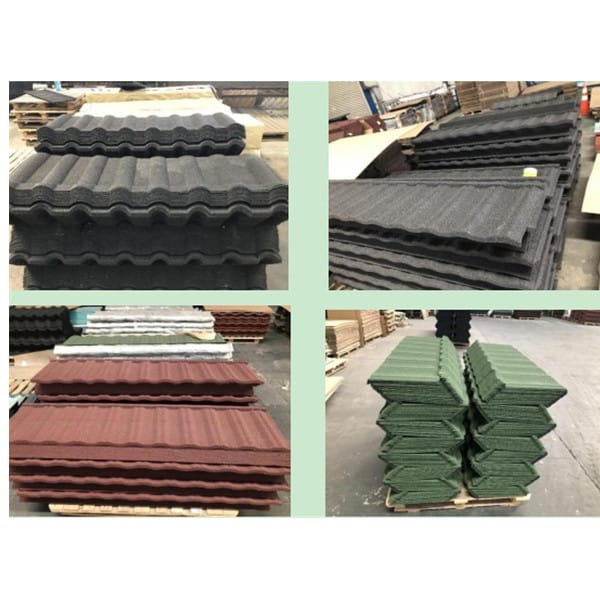

Finish products show

Package

Fumigation free wooden pallet packaging suitable for long-time and long-distance maritime transportation. The packaging is supported and reinforced around, wrapped with film, safe and stable, and effectively protect the products from damage during transportation.

Here is the video of our stone coated metal roof tile and production line.

Here is the stone coated roofing tile production line working video for your reference: