Flush Wall Soffit Panel forming Machine

Description:

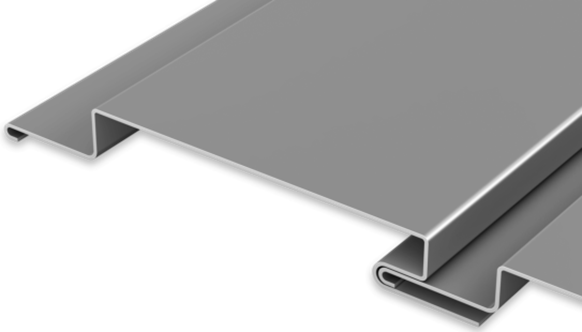

Flush panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system improves the flush appearance while providing additional strength. Panels are factory-formed to length to minimize field cutting. Maximum panel length is 25' and minimum panel length is 4'. Flush panels are available in on-center dimensions designed to complement Petersen’s roofing panel product line. Flush panels are available in Flush and Reveal joint configurations.

The machine produces panels for Flush panels. The machine works with all types of roof covering: steel (including polymer-coated), copper (including painted), aluminum, zinc, aluzinc, zinc-titanium. The material may be in rolls or in sheets. Optimized configuration of grading rollers ensures high quality of the profile.

Distinctive feature of the machine:

Use the handle to control the machine whether to emboss the panels;

The PLC control system can realize the control of the production speed(0-12 m/min), and can also control the length of the cutting panels to achieve automated production;

Suitable for use both in the workshop and on site;

Manufactures roofing panel-painting line and trapezoidal shape, as well as a one-way seam;

high quality of products through the use of an optimized design;

the use of complex composite rollers completely eliminates damage to the polymer coating of metal;

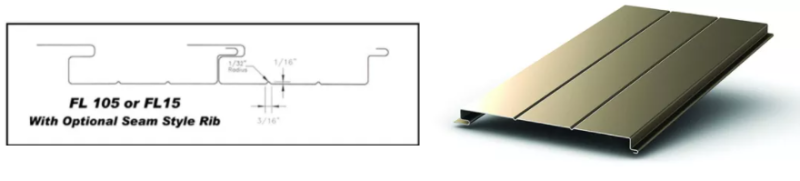

Customer drawing profile:

Thickness range: 0.2 to 0.8mm, Coil width: 381mm(15 inch) Effective width :279.4mm(11inch)

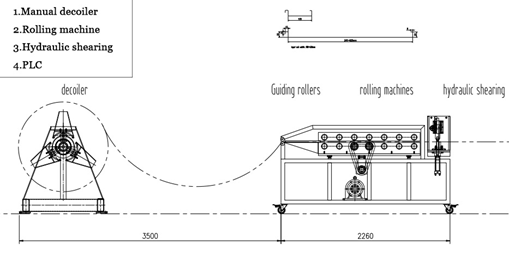

The machine is composed by the following elements:

Decoiler Options | 5t decoiler Manual (for free) / Automatic(Extra charge) |

Working speed | 12 meter/min |

Power | 15kw |

Voltage | Customize |

PLC system | Delta |

Machine size | 3.3x1.3x1.5 meter |

Machine weight | 1.8t |

Roller station | 14 roller station |

Machine pictures for your reference:

This is PLC Control System, you can adjust the speed and the length of cutting, it can realize automate produce.