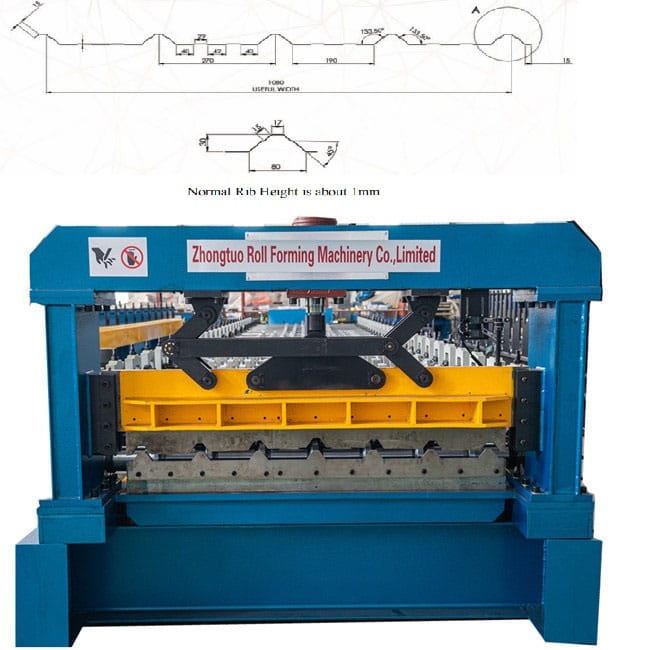

Molding Frame Strong Version Trapezoidal Metal Roofing Sheet Roll Forming Machine

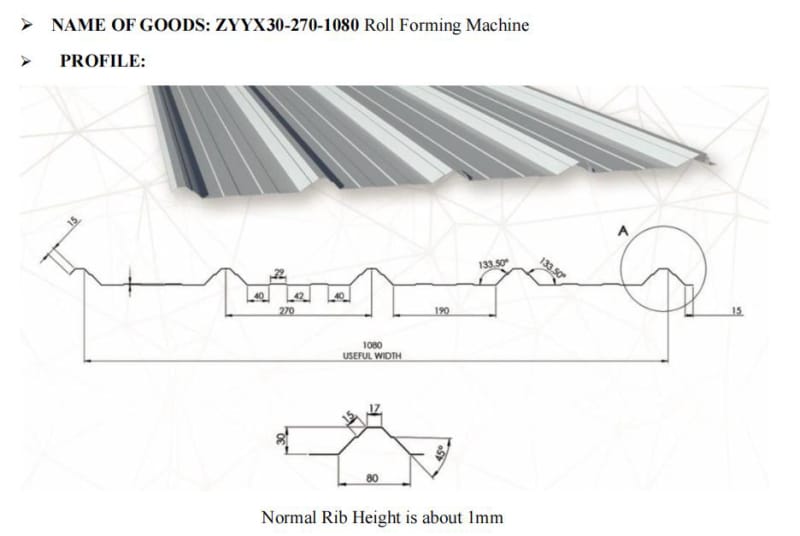

Door structure trapezoidal metal roofing sheet roll forming machine is designed to make the metal trapezoidal IBR roofing sheet machines in batch fully automatically. This machine is good for those who has strong desire to buy some good machines, as it uses the molding frame which thickness is around 35 to 45 mm thickness. And the machine rolling forming takes the separated molding rolling forming to enhance the machine working speed. Here I will take some random popular drawing from Egypt for your reference:

Ø MATERIAL:

1) Coil Width: 1250mm

2) Suitable Coil Thickness: 0.3 mm-0.7mm

3) Suitable Raw Materials: Color steel sheet

4) Yield strength of raw material: 235Mpa

Main rolling forming machine features:

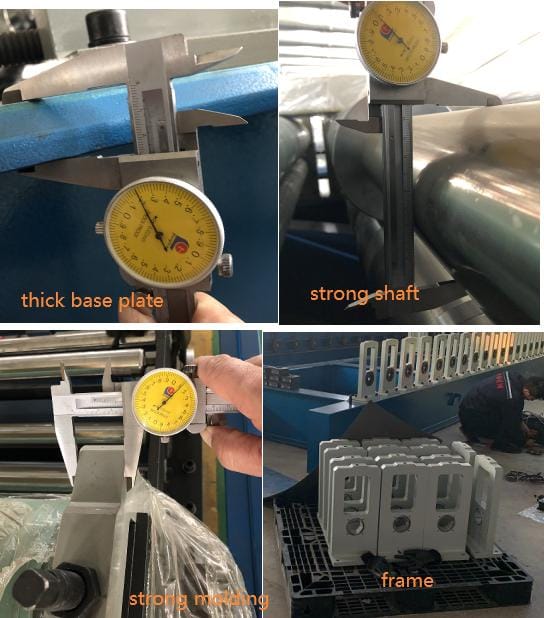

1) The main frame of machine is welded separately and the outside wall is connected by screw after being rotoblasted on the surface.

2) Roller Material is high grade No.45 forged steel, with digital-controlled procession.

3) Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

4) The rollers are plated with hard chrome with thickness of 0.05mm on the surface after being machined by the exact machine tool. So that ensures long life of forming rollers.

5) Shaft diameter is 72mm.

6) Quantity of forming rollers : about 16 stations (Depend on final design, but machine length will be controlled within 7.5 meters length)

7) Adding bearings inside the rollers.

8) Chain and gear move the line, motor drives. All working actions are controlled by PLC electric cabinet automatically.

9) Suitable power voltage:380V/50HZ/3Phase (can be designed according to buyer’s requirement)

10) Line working speed (Forming speed): about 20-25m/min (without cut time)

11) Main machine motor power: about 5.5KW (Depend on final design)

Feeding table or leveling beach:

1. Pre-manual cutter to cut at any length or cut the start of untidy part.

2. Carrier roller can protect your coil from scratch.

3. Film device can loading plastic film and covered on the roof sheet

4. The rubber roller can help feeding the material into machine faster.

5. The machine can roll forming 1220 mm & 1450 mm two kind of width. Here has hand wheel on one side to adjust the feeding width.

For this type design, it could be used to design any roofing profiles, like round wave or step tile and other IBR tiles. Here are more details of elements for your reference.

Molding frame trapezoidal metal roofing sheet rolling forming machine working video for your reference: