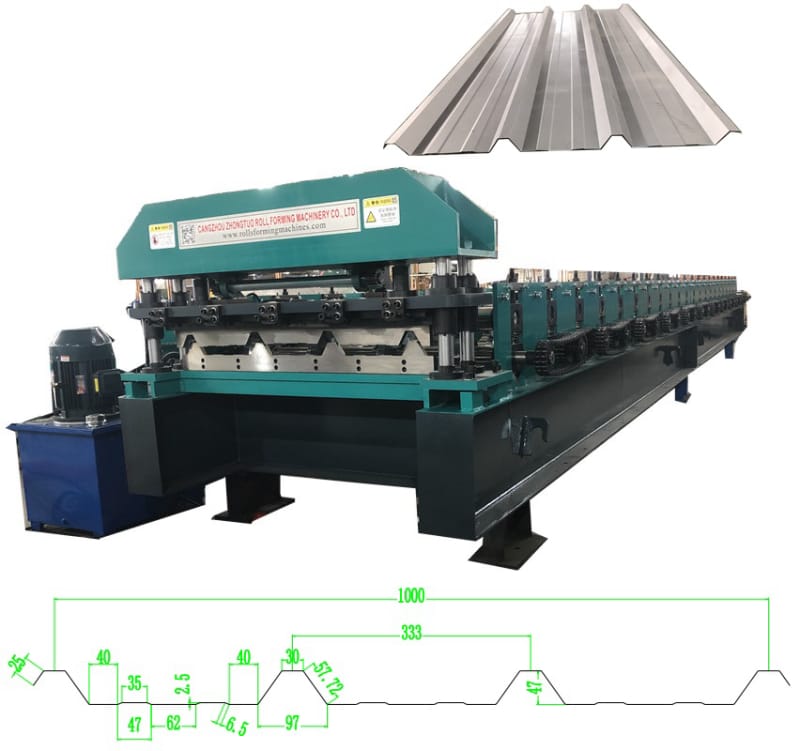

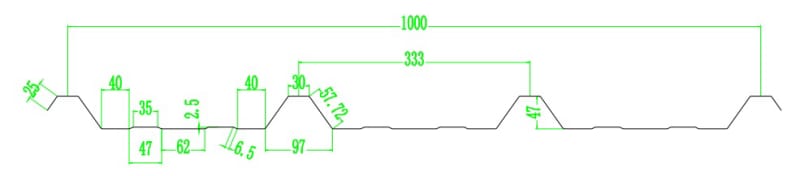

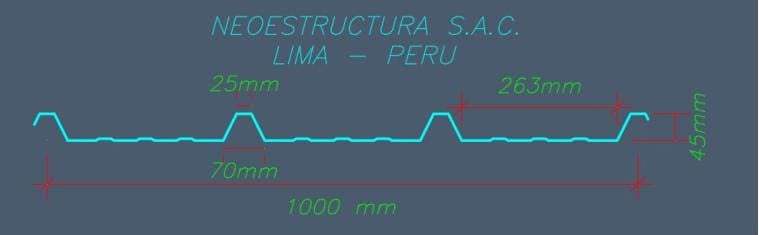

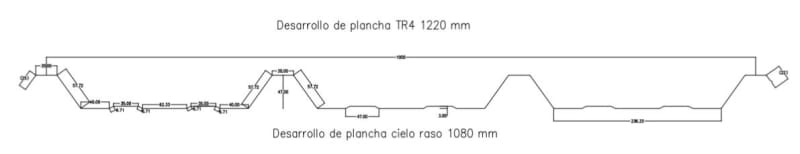

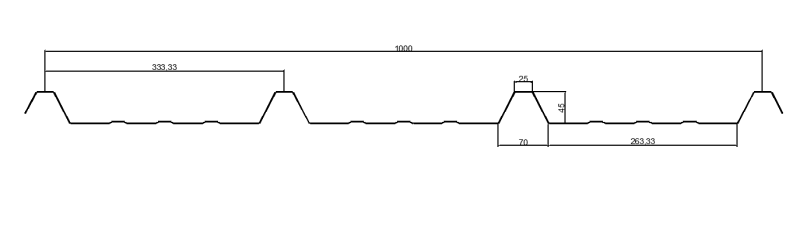

TR4 roofing sheet roll forming machine is designed to produce TR4 metal roofing sheet which is very popular in Peru Market in batch automatically. TR4 refers to the trapezoidal roofing sheet profile with four waves. According to the requirements of different customers, the waves height and distance will be slightly different, but the effective width is basically kept at 1000mm, and the color steel coil with a width of 1220mm is used for production.

Here are some TR4 profiles for your reference.

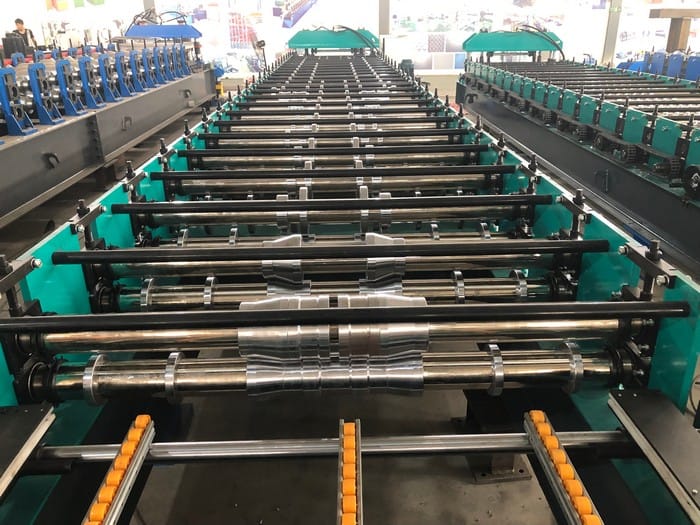

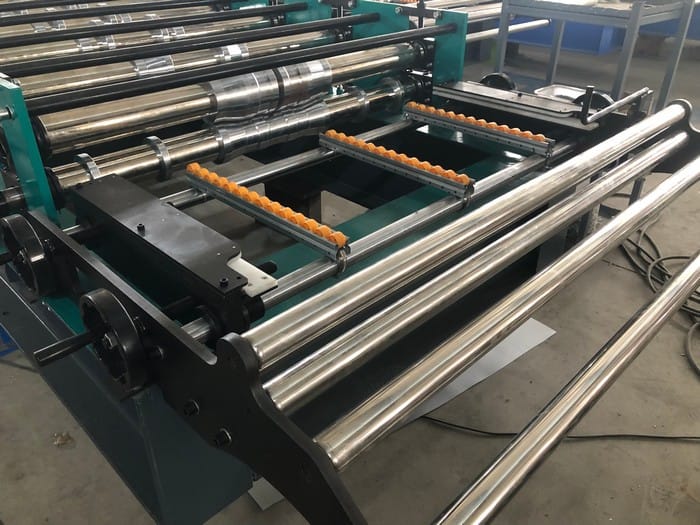

With many years experience and professional R & D team, we can provide our customers with more suitable machine solutions according to theis requirement. Here are some picetures of TR4 roofing sheet roll forming machine for Peru Market.

Technical parameter and feature of TR4 roofing sheet roll forming machine

Power: 11KW

Roller stations: 22

Roller shaft: 80mm, solid steel

Rollers: 45# steel, hard chrome coated

PLC: Delta, touch screen, multi order support

Hydraulic shearing system: double pillar structure

Cutting blade material: GCr12, HRC58-62

Production speed: 0-20m/min

Machine frame: 400H high grade steel

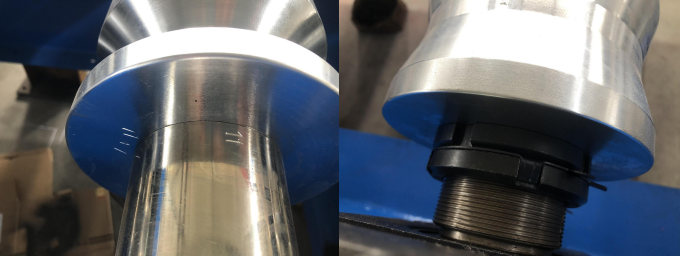

Strong solid steel shaft with key-way, the machine runs more stable.

Zhongtuo machines have more big rollers and more thicker spacer, they can avoid deviation of coil during forming and

guarantee a faster production speed, as well as the precise shape and size of the roofing sheet.

Marked with letter or number on each roller and shaft, easy to maintenance.The design of double nut and thrust pad will not

loosen even used continuously for a long time.

PLC control system, use famous brand siemens or delta, as your requirement

The wiring in the electrical cabinet is neat, and low voltage electrical components adopt Schnerder brand, more safety.

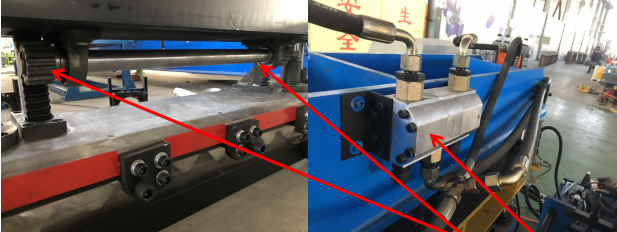

In order to ensure the same cutting force at both ends of the blade, we also added a balance shaft or diverter, which also

prolonged the service life of cutting system.

Equipped with fan on the tank, in case the oil temperature getting hot when the machine working for hours continuously, ensure the hydraulic oil in a constant temperature to have enough power for cutting device.

For more information, please contact with us. And here is the machine working videos for your reference:

<